Halliburton SP 7 inch TR-SCSSSV

SCSSSV SP

Also known as:

SCSSV, surface controlled subsurface safety valve, SCSSSV

Halliburton SP 7 inch TR-SCSSSV

SCSSSV SP

Also known as:

SCSSV, surface controlled subsurface safety valve, SCSSSVBuy

Made to Order

Product

New

API

Air Freight

Price:

Based on specifications Request for QuoteShipping:

Air freightDelivery Time:

4 weeksNote:

MTM thread sealing and self-locking capabilitySign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Technical Specifications

| Condition | New |

| Material | Steel |

| Price | Based on specifications |

| Company Type | Product Provider |

| Transaction Type | Buy |

| Weight | Less than 250 kg |

| Brand Name | Halliburton |

| Location | United states |

| Quality Assurance | API |

| Shipping | Air freight |

Features and Benefits

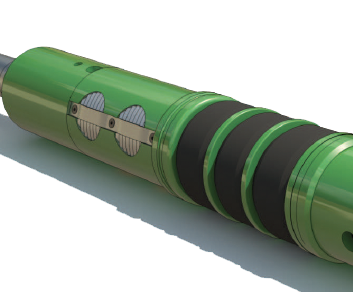

- Unsurpassed reliability of hydraulic actuator; dynamic and static seals independently verified gas tight

- Control line isolated from well fluids by MTM seal with valve in closed position

- Hydraulic system isolated from well pressure by MTM seal with valve in open position

- MTM thread sealing and self-locking capability

- Fluted guide provides maximum debris protection, allowing fluids to enter and exit during valve operation

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

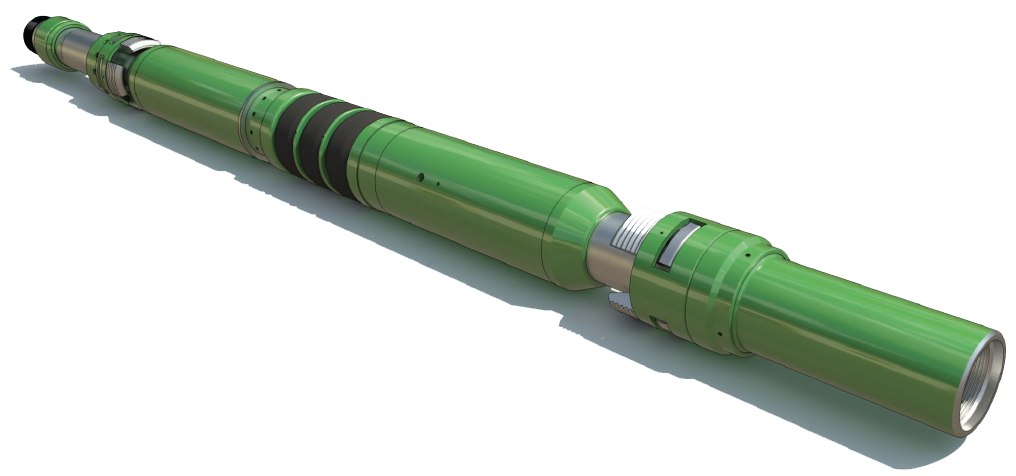

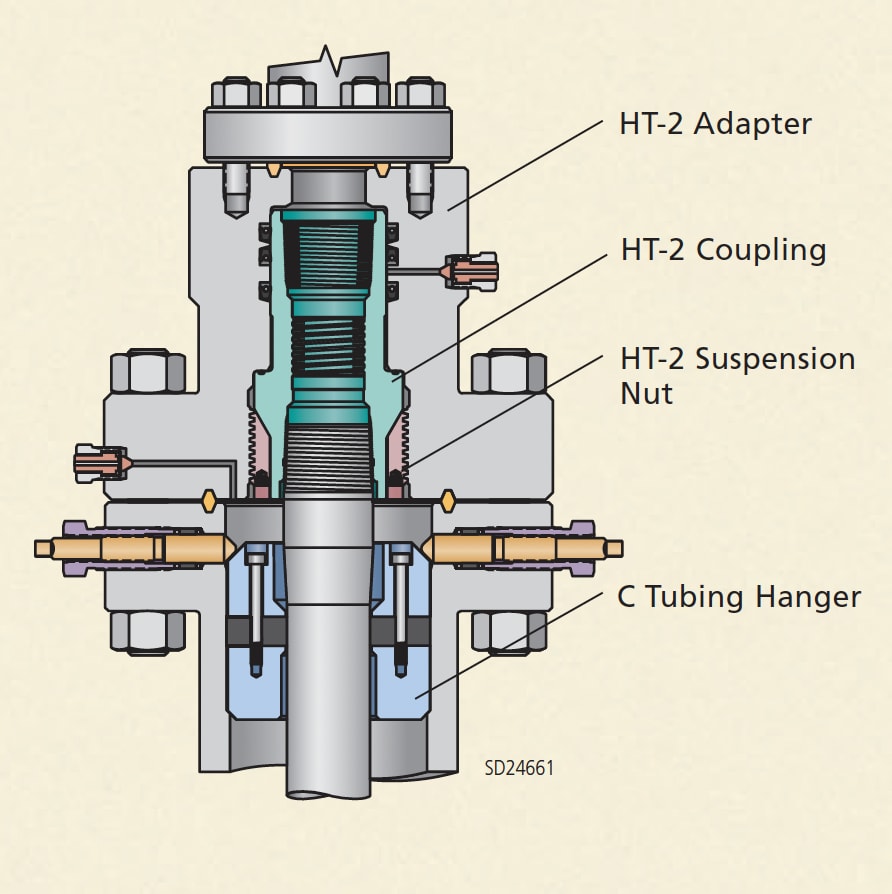

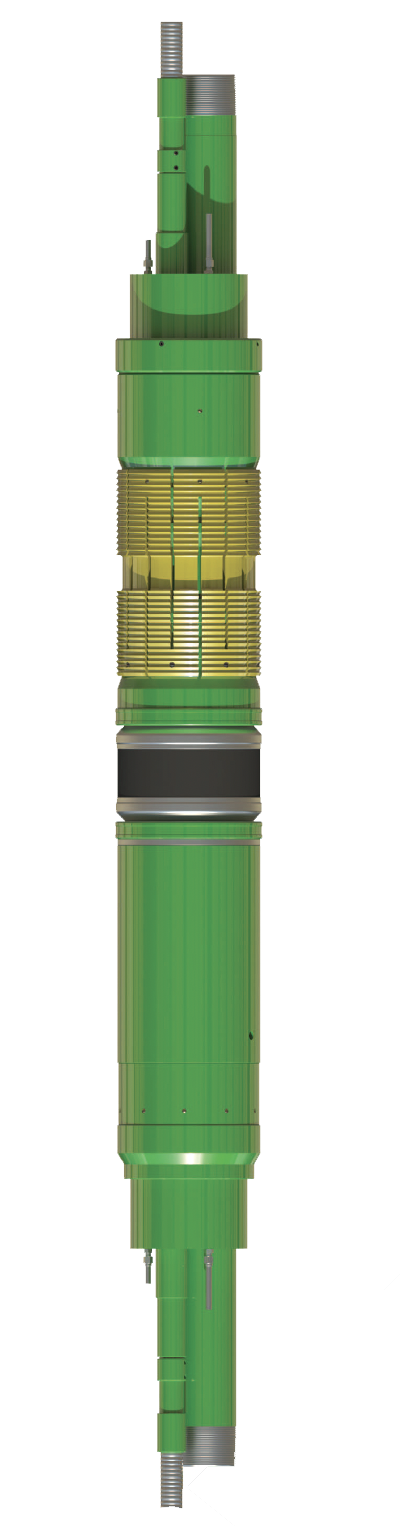

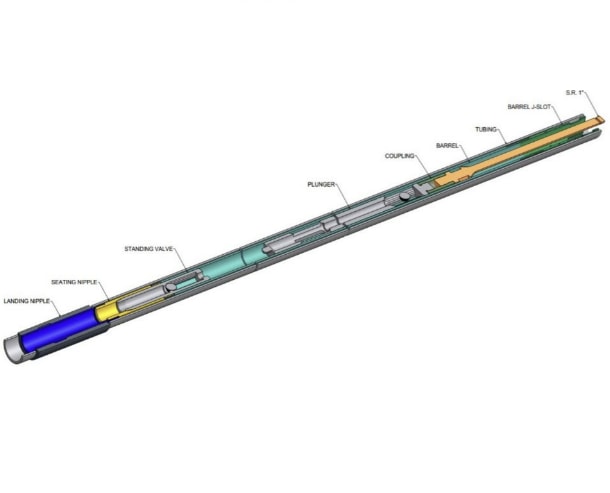

The SP™ tubing-retrievable safety valve (TRSV) is a single rod-piston non-elastomer flapper valve designed for hostile environments and extended life applications where ultimate reliability is required.

Potential leak paths within the valve are minimized with the single rod-piston design. The piston achieves a metal-to-metal (MTM) seal at its uppermost and lowermost positions to seal well pressure from the control system.

The SP valves incorporate flappers using spherical radius sealing surfaces that help greatly improve seal reliability.

The spherical radius design provides full MTM sealing integrity.

For applications where either the OD or ID is restrained, SP valves incorporate a contoured flapper. OD/ID relationships are improved by the contoured flapper design, which helps provide superior MTM sealing when compared to other forms of curved flapper technology.

Applications

» For applications requiring ultimate reliability and longevity, such as high-temperature/high-pressure, and subsea completions, or hostile well environments

Features

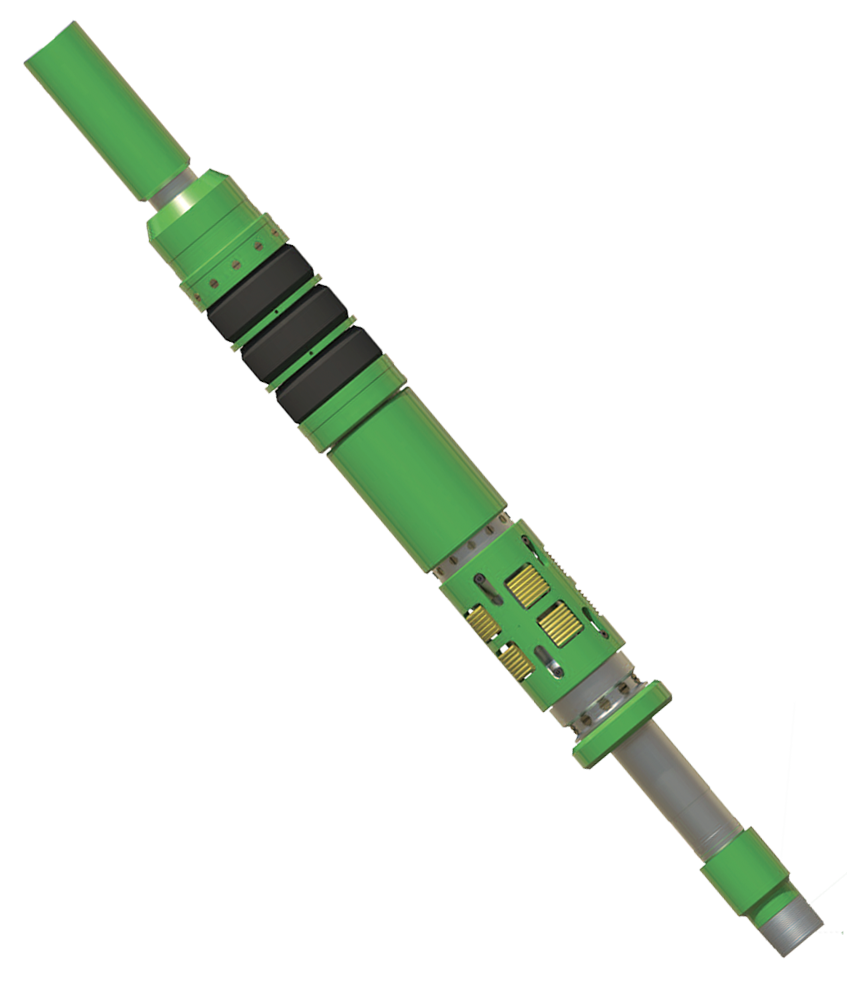

» Non-elastomer dynamic piston seals

» MTM static seal at upper and lower piston positions

» MTM body joints

» Flow tube fluted guide

» 100% MTM flapper

» Concentric thrust bearing

» Wiper ring on upper flow tube

» Cleanout ports in flow tube’s upper end

» Internal exercise profile

» Flow tube shock absorber

» MTM face seat at flow tube downstop

» Setting depths to 9,000 ft (2743 m)

» Critical components isolated from well debris with valve in open position

» Area above flow tube free of solids buildup

» Flow tube can be manipulated by slickline

» Protected from high flow rate slam closures

*information referenced from supplier catalog.