Rod Sentinel - Rod Pump SCSSV

Sucker Rod Surface Controlled Subsurface Safety Valve for beam pump

Also known as:

ISRSCSSV, Sucker Rod Safety Valve, Dual Barrier Rod Pump

Rod Sentinel - Rod Pump SCSSV

Sucker Rod Surface Controlled Subsurface Safety Valve for beam pump

Also known as:

ISRSCSSV, Sucker Rod Safety Valve, Dual Barrier Rod PumpBuy

In Stock

Manufacturer

New

API

Air Freight

Price:

Request for QuoteShipping:

Air freightDelivery Time:

ImmediatelyNote:

The first fail safe insert sucker rod surface controlled subsurface safety valve (ISRSCSSV)Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Technical Specifications

| Condition | New |

| Material | Steel |

| Company Type | Manufacturer |

| Transaction Type | Buy |

| Weight | Less than 50 lbs |

| Brand Name | Sivam |

| Location | Italy |

| Quality Assurance | ISO |

| Shipping | Air freight |

Video

Features and Benefits

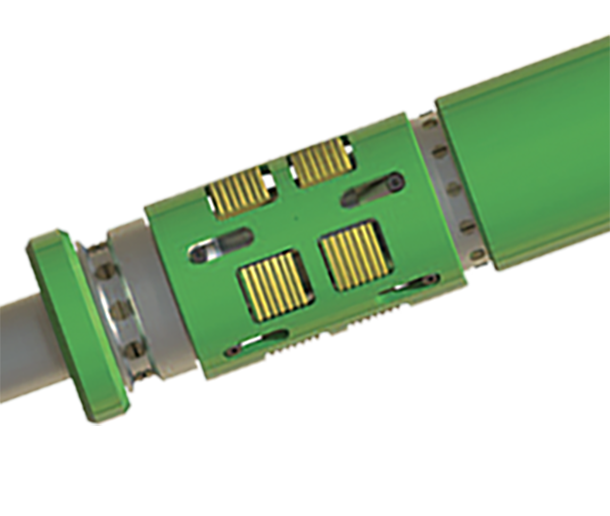

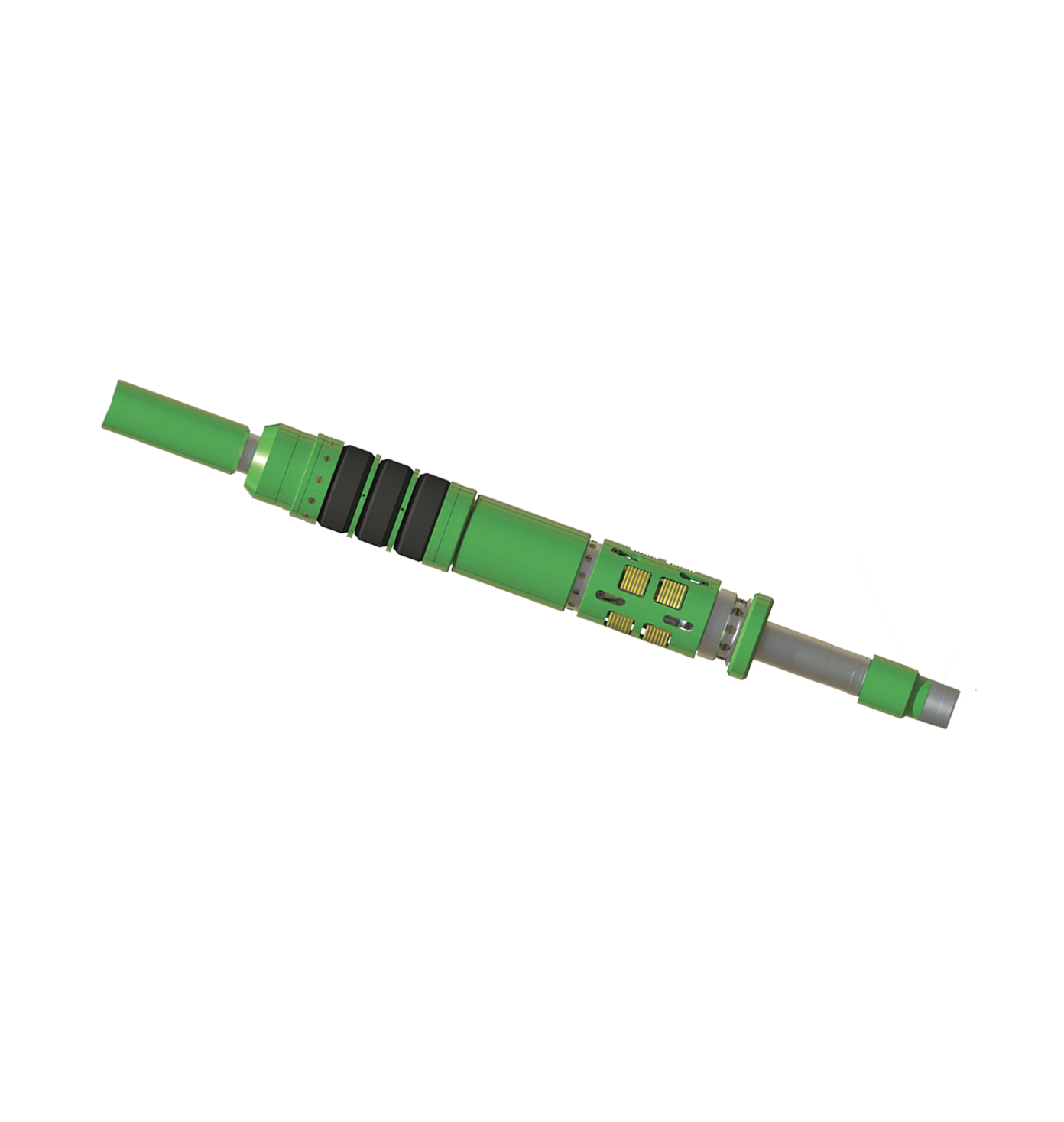

- Innovative system to provide dual barrier safety in wells completed with sucker rods

- Large flow path

- Seal pads embrace the sucker rod only when the control line pressure drops

- No stroke limitations

- Can be seated in a conventional SCSSV seating nipple profile

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

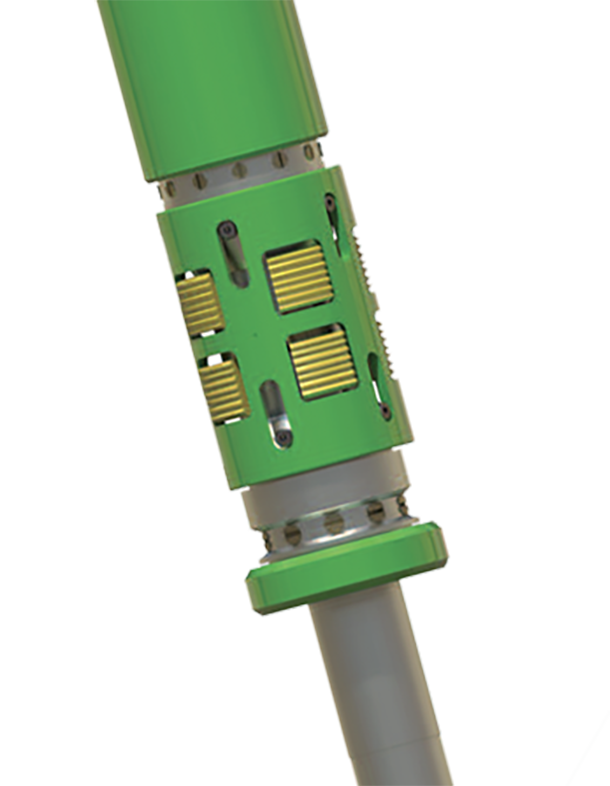

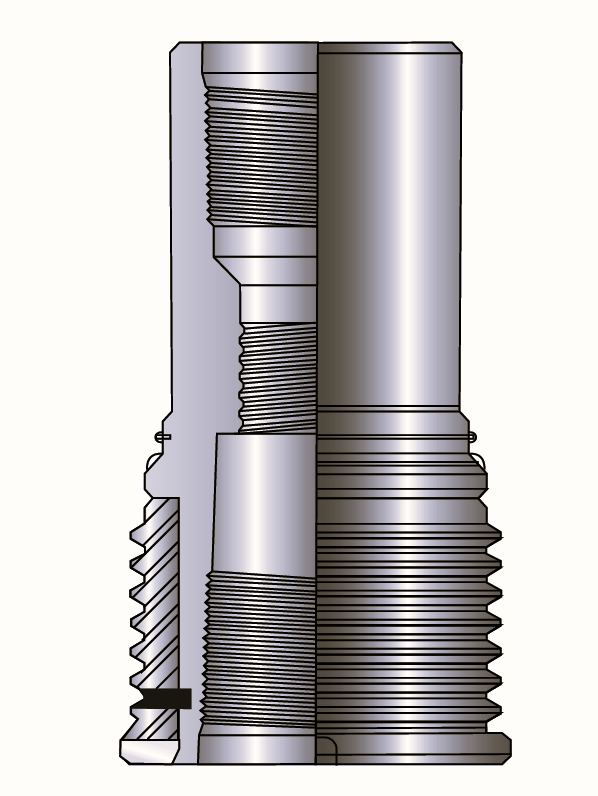

Introducing the Rod Sentinel. Sivam has designed and patented the first fail safe, surface controlled subsurface safety valve for sucker rod application called rod sentinel - an innovative technology that changes the game in dual barrier policy of the oil and gas market. This Sivam safety valve can be applied in all sucker rod completed wells where it is necessary to comply with the dual barrier policy. The Rod Sentinel SCSSSV can be installed in landing nipple for 2.81 inches surface controlled wireline retrievable insert valves with standard profiles. The Rod Sentinel SCSSSV lock mandrel has been designed to be installed and retrieved by the sucker rod string in combination with the pump plunger so it completely avoids the cost and risk of a workover. The beam pump safety valve was designed in compliance with the fail-safe concept. Control line pressure keeps the valve open and when the pressure fails the preloaded power spring in the valve pushes the sealing pads within the cone housing and the valve closes using the same hydraulic control line technology as a conventional SCSSSV.

Engineering Data