Ball Valve Lever Operated – 2-Way Male x Female End Connection – 1/4”, 3/8”, 1/2”, 3/4”, 1” – 6000 PSI – ASME B16.34 / ISO 9001

Ball Valve

Also known as:

Shut-off Valve, Quarter-turn Valve

Ball Valve Lever Operated – 2-Way Male x Female End Connection – 1/4”, 3/8”, 1/2”, 3/4”, 1” – 6000 PSI – ASME B16.34 / ISO 9001

Ball Valve

Also known as:

Shut-off Valve, Quarter-turn ValveBuy

In Stock

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

6 - 8 WeeksNote:

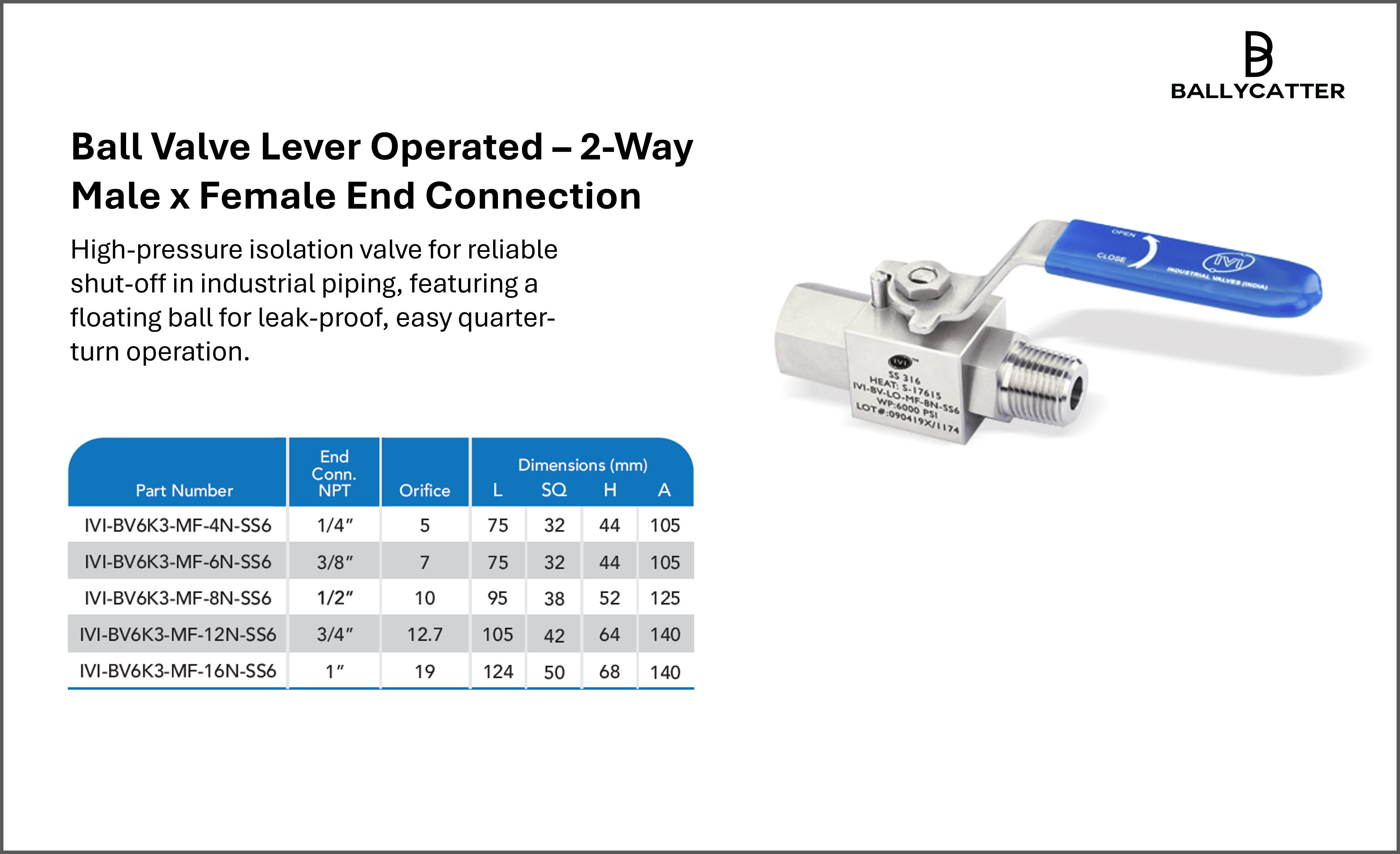

Ball Valve Lever Operated – 2-Way Male × Female is a high-pressure isolation valve for reliable shut-off in industrial piping, featuring a floating ball for leak-proof, easy quarter-turn operation.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

The Ball Valve Lever Operated – 2-Way (Male × Female) is a high-pressure isolation valve for controlling or shutting off fluid flow in industrial piping systems.

It features a lever-operated floating ball design, providing quarter-turn operation and leak-proof sealing under pressures up to 6000 PSI and temperatures from –40 °F to 450 °F (–40 °C to 232 °C).

The valve is constructed for industrial use with replaceable seats and robust components, suitable for oil and gas applications.

Technical Specifications

| Connection | Male × Female |

| Standard Working Pressure | 6000 PSI |

| Maximum Working Pressure | 10000 PSI (on request) |

| Temperature Rating | –40 °F to 450 °F (–40 °C to 232 °C) |

| Design Standard | ASME B16.34 |

| Pressure-Temperature Rating | ASME B16.34 |

| Piping Code | ASME B31.3 |

| Type Test | MSS-SP-99 |

| Flow | Bi-Directional |

| Configuration | 2-Way straight |

Features and Benefits

- Internally loaded stem with shoulder.

- 2-Way floating ball design.

- Leak-proof shut-off even at high pressure.

- Maintains sealing performance over long service life.

- Suitable for high-pressure, industrial applications.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The Ball Valve Lever Operated – 2-Way (Male × Female) is an isolation valve used to start, stop, or regulate fluid flow in oil and gas piping systems. Its 2-way design provides simple, reliable flow control, making it ideal for applications where full shut-off or bi-directional flow is required, such as upstream production lines, downstream processing, pipeline distribution, and injection systems.

The valve features a floating ball design for seat wear compensation and leak-proof performance under high-pressure conditions. It is manufactured and tested to ASME B16.34, meets ASME B31.3 pressure-temperature ratings, and is type-tested to MSS-SP-99. It supports bi-directional flow with a standard working pressure of 6000 psi (maximum 10000 psi on request) and a temperature range of –40 °F to 450 °F (–40 °C to 232 °C).

It operates via a quarter-turn lever with low torque. The stem is internally loaded with a shoulder to prevent blowout. Replaceable seats and packings extend service life, and the maximum orifice minimizes pressure drop. The valve is factory tested with nitrogen gas at 1000 psig (maximum leak rate 0.1 sec/min). Optional tests include vibration, temperature, and helium. It can also meet NACE MR0175 standards and fire-safe requirements, with heat code traceability for all components.

In conclusion, this 2-way ball valve provides reliable, leak-proof isolation for critical oil and gas operations, combining robust construction, high-pressure capability, and ease of operation to ensure safe and efficient flow control across the system.

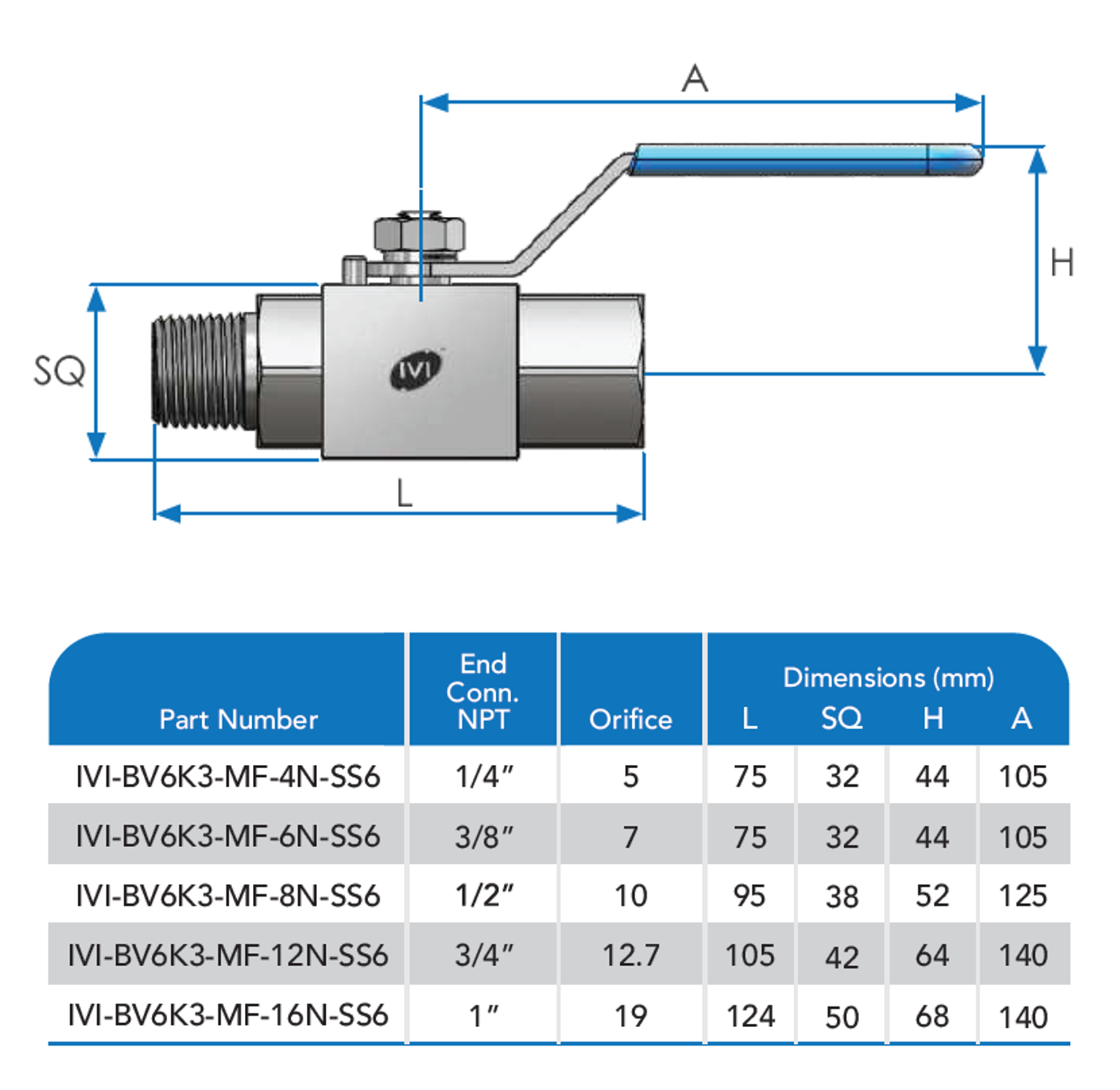

Engineering Data