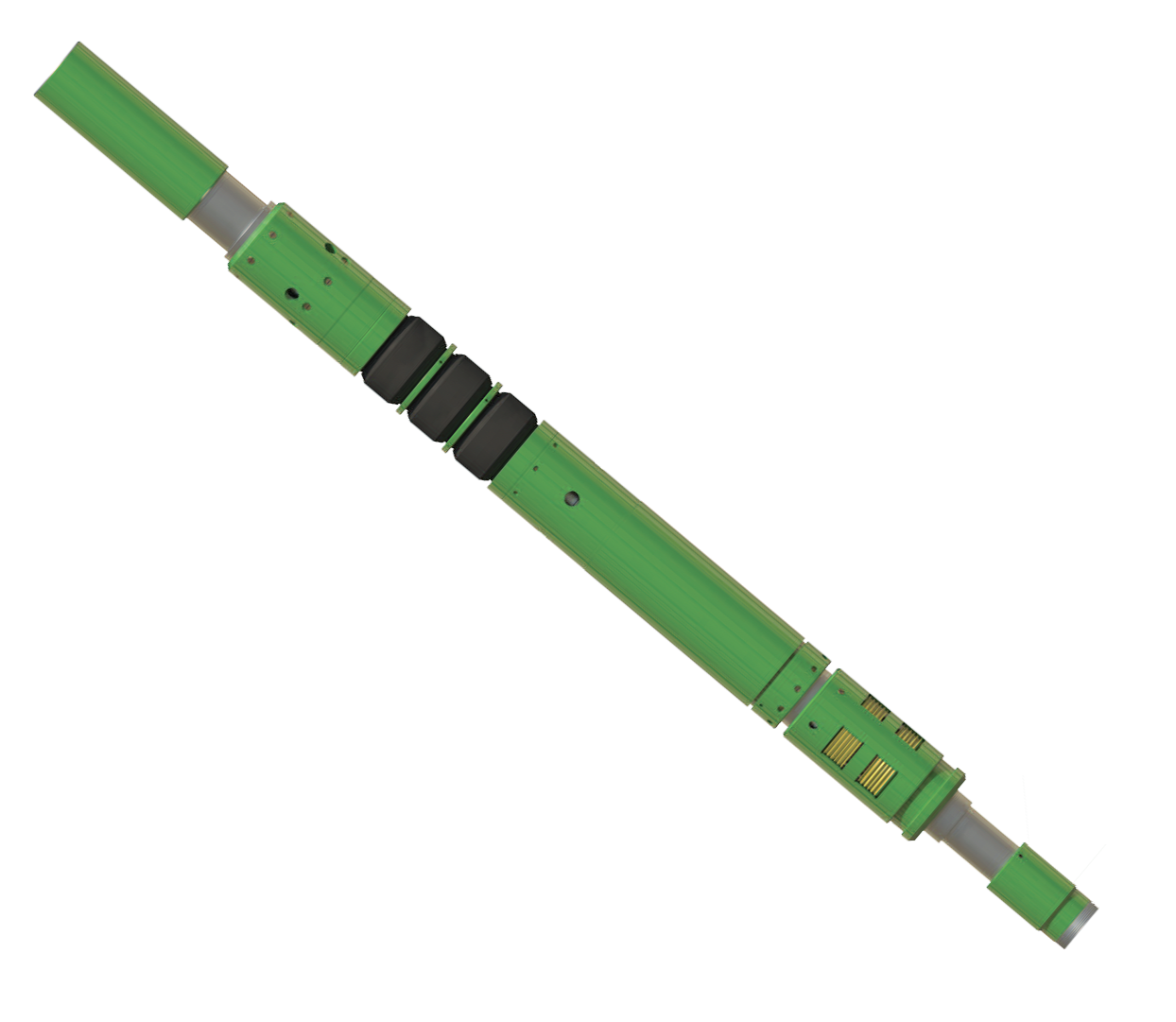

ESP 9 5/8” Production Packer

Hydraulic Set Electric Submersible Pump Production Packer

Also known as:

ESP Packer

ESP 9 5/8” Production Packer

Hydraulic Set Electric Submersible Pump Production Packer

Also known as:

ESP PackerBuy

Made to Order

Manufacturer

New

API

Air Freight

Price:

Request for QuoteShipping:

Air freightDelivery Time:

12 weeksNote:

The dual-bore design allows for a pass-through section, enabling the electric cable to reach the ESP below the packer.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

Hydraulic-Set, Dual-Bore Design

•The ESP packer is set in place using hydraulic pressure applied through the tubing as it is a single-mandrel, dual-bore, hydraulic-set production packer.

•The dual-bore design allows for a pass-through section, enabling the electric cable to reach the ESP below the packer.

Technical Specifications

| Packer Size | 9 5/8" |

| Casing Weight | 9 5/8" (40-47 PPF) |

| Min Yield Strength | 80,000 PSI |

| Material | AISI 4130/4140/4145 Q L80 |

| Elatomer | HNBR |

| OD | 8.500" |

| ID (Main Bore) | 2.441" |

| Setting Pressure | 3500 PSI |

| Cable - Inj Line ID | N/A |

| Feedthru amount | 1 |

Video

Features and Benefits

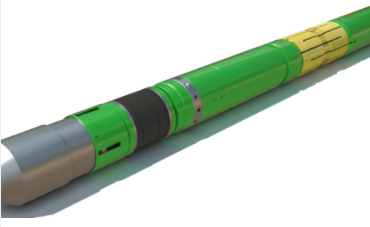

- Bi-directional barrel-slip design provide high loading capacity and uniform transfer of load

- Single-piece mandrel construction

- Single-trip capability

- Penetrator available with 1” flat and round cable

- Flexibility for different well conditions

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

Electrical Submersible Pump Packer

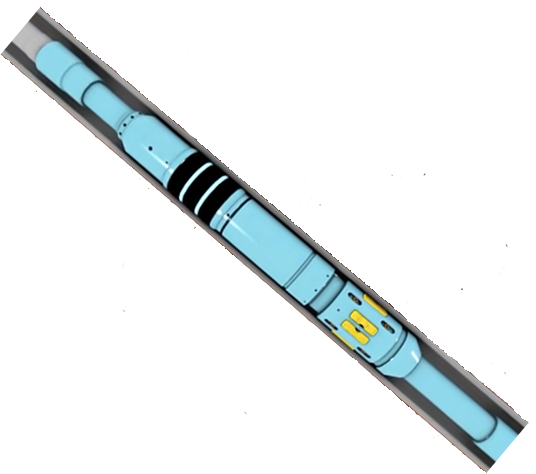

A downhole Electric Submersible Pump (ESP) Packer for a 9 5/8” casing is a critical component in artificial lift systems, designed to provide a secure, pressure-tight seal between the tubing and casing while allowing the electrical cable to pass through to the ESP. Here’s how it works:

1. Hydraulic-Set, Dual-Bore Design

This single-mandrel, dual-bore packer is hydraulically set by applying fluid pressure through the tubing. This eliminates the need for mechanical manipulation, making it an effective choice for deviated or high-angle wells where mechanical setting might be challenging.

• The dual-bore design incorporates a dedicated pass-through bore, allowing the power cable to run from the surface, through the packer, and down to the ESP below.

• This configuration enables uninterrupted power delivery to the pump while maintaining zonal isolation in the wellbore.

2. Bi-Directional Slip System for Secure Anchoring

Once hydraulic pressure is applied, the case-carburized bi-directional slips engage against the casing wall.

• These slips are hardened to withstand high loads and anchor the packer firmly in place to resist both upward and downward forces caused by reservoir pressure fluctuations and ESP-induced pressure differentials.

• This ensures that the packer remains securely in position, preventing unintended movement during production or shutdown cycles.

3. Versatile Release and Retrieval Mechanism

When it’s time to retrieve or replace the ESP system, the packer features a flexible release system:

• The standard retrieval method involves applying a straight upward pull on the tubing, which disengages the slips and allows the packer to be removed.

• Alternatively, for applications where higher retrieval forces might be impractical, a cut-to-release option is available, enabling efficient removal in more challenging well conditions.

Operational Advantages

• Reliability in High-Load Applications: Designed to handle the extreme downhole conditions associated with ESP operations, including high fluid flow rates and pressure fluctuations.

• Adaptability to Various Completion Designs: The dual-bore configuration accommodates different ESP setups and cable-routing requirements.

• Efficiency in ESP Deployment: By securely isolating production zones while allowing cable pass-through, the packer streamlines the ESP installation process and enhances system integrity.

This ESP packer plays a vital role in ensuring reliable artificial lift performance, particularly in deep or high-pressure wells where stable downhole conditions are essential for maximizing production efficiency.