Hydraulic Set Production Packer

15K Cut to Release Hydraulic Packer

Also known as:

Permanent Packer

Hydraulic Set Production Packer

15K Cut to Release Hydraulic Packer

Also known as:

Permanent PackerBuy

In Stock

Manufacturer

New

API

Air Freight

Price:

Request for QuoteShipping:

Air freightDelivery Time:

4 weeksNote:

The Ballycatter WC-HP-15 Hydraulic Set Production Packer delivers high-pressure, high-temperature reliability with the convenience of a retrievable design, optimizing well integrity and efficiency.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

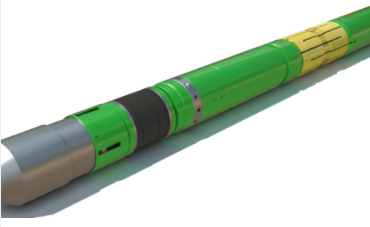

The Ballycatter WC-HP-15 Hydraulic Set Production Packer is a hydraulic-set cut to release packer that combines the pressure and temperature ratings and reliability of a permanent packer with the convenience of a retrievable packer. Once the packer is runny set, it is released by cutting the mandrel. When the mandrel is cut the packer will release and all of the packer components along with the tailpipe can be retrieved from the well.

Technical Specifications

| Size (in.) | 7 |

| PPF Range | 35 - 38 |

| OD (in.) | 5.730 |

| ID (in.) | 2.750 |

| Diff. Press. Rating (psi) | 15,000 |

| API 11D1 Validation Grade | V0 - V3 |

Features and Benefits

- Anti-Preset - Prevents Packer from setting until a set tubing pressure is applied

- Anti-Reset - A snap ring engages the mandrel when the packer is set, locking the lower cone in place.

- Barrel slip design for high load capacity

- No milling required to retrieve

- Metal-to-metal backup shoes with 360 degree casing wall contact

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The Ballycatter Hydraulic Set Production Packer 15K (Cut to Release) is a state-of-the-art downhole tool engineered to deliver the robustness of a permanent packer with the added convenience of retrievability. Designed for high-pressure (up to 15,000 psi) and high-temperature (up to 450°F) environments, this hydraulic-set packer is ideal for challenging well conditions.

Key Features:

• Anti-Preset Mechanism: Ensures the packer remains unset until a predetermined tubing pressure is applied, preventing premature setting during deployment.

• Anti-Reset Functionality: Upon release, a snap ring engages the mandrel, locking the lower cone in place to keep the barrel slip retracted, facilitating smooth retrieval.

• Propped Element Design: Offers superior sealing capabilities, maintaining integrity under extreme conditions.

• Barrel Slip Configuration: Located below the elements, it uniformly distributes loads to the casing, enhancing stability and performance.

• Metal-to-Metal Backup Shoes: Provide 360° casing wall contact, ensuring reliable element containment and preventing extrusion.

• No Mandrel Movement Operation: Simplifies the setting process and reduces potential operational issues.

Benefits:

• Eliminates Milling Requirements: The packer can be retrieved without the need for milling, streamlining the retrieval process.

• Enhanced Sealing and Retrieval Reliability: Combines robust sealing mechanisms with dependable retrieval features to ensure operational success.

• Reduced Rig Time: Efficient design minimizes time spent during both completion and decompletion phases, leading to cost savings.

Applications:

• Suitable for hot, corrosive, deep, and deviated wells, whether for production or testing purposes.

• Ideal for scenarios where minimal casing deformation or damage is critical.

• Supports single-trip completions and multi-packer installations.

• Effective for liner top isolation and monobore completions.

Available Sizes:

• Compatible with casing sizes ranging from 5-1/2 inches to 7-5/8 inches.

For detailed specifications, please refer to the product’s specification sheet.

The Ballycatter Hydraulic Set Production Packer 15K (Cut to Release) stands as a reliable solution for operators seeking a balance between the durability of permanent packers and the flexibility of retrievable systems in demanding well environments.