Coiled Tubing Motorhead Assembly – 2-1/8”, 2-7/8” – Up to 15,000 PSI – ISO

MHA Motorhead Assembly

Also known as:

Coiled Tubing Downhole Tool, BHA

Coiled Tubing Motorhead Assembly – 2-1/8”, 2-7/8” – Up to 15,000 PSI – ISO

MHA Motorhead Assembly

Also known as:

Coiled Tubing Downhole Tool, BHABuy

Made to Order

Manufacturer

Price:

Request for QuoteShipping:

Land freightDelivery Time:

4 - 6 WeeksNote:

The Coiled Tubing Motorhead Assembly is a downhole tool used in coiled tubing operations that provides well control through dual check valves, allows circulation for well cleaning, and features a hydraulic disconnect for controlled separation of the tubing and tool string.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

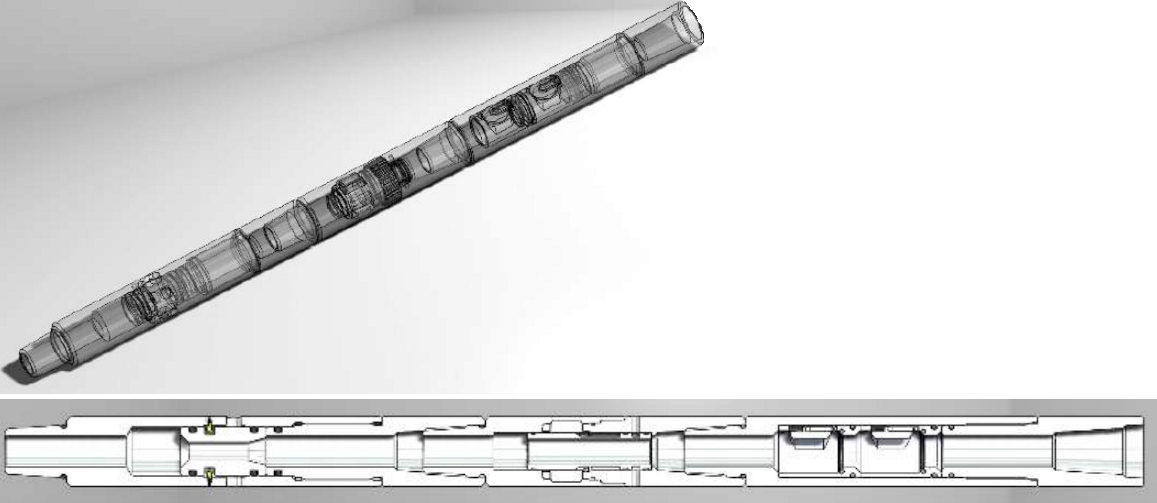

The Coiled Tubing Motorhead Assembly is run as part of the coiled tubing bottom hole assembly and provides essential functions for safe and controlled well intervention operations. It is designed to maintain well control, enable fluid circulation, and allow emergency disconnection of the tool string when required.

The assembly incorporates dual check valves to prevent backflow, a hydraulic disconnect for releasing the coiled tubing if tools become stuck, and a circulation valve for managing fluid movement in the wellbore. It is installed above the downhole motor or used independently in other downhole assemblies as part of routine and contingency well intervention practices.

Technical Specifications

| Sizes | 2-1/8”, 2-7/8” |

| Max OD | 42.9 – 73.0 mm |

| Min ID | 11.1 – 17.5 mm |

| HDI activation ball size | 15.9 – 22.2 mm (0.625" – 0.875") |

| DCS Activation Ball Size | 12.7 – 19.1 mm (0.500" – 0.750") |

| Thread Connections | 1.0" AMMT, 1.5" AMMT, 2-3/8 PAC |

| Applicable Standards | ISO |

| Working Pressure | Up to 15,000 PSI |

| Material | Alloy steel, corrosion and wear resistant |

| Key Components | Valves, disconnect, circulation |

Features and Benefits

- Dual check flapper valves to prevent backflow of well fluids.

- Provides reliable well control during coiled tubing operations.

- Improves wellbore cleaning and circulation efficiency.

- Built for high-pressure and high-temperature conditions.

- Simplifies tool configuration and operations.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The Coiled Tubing Motorhead Assembly is a downhole tool used in coiled tubing operations to provide well control, manage fluid circulation, and allow safe emergency disconnection of the tool string if needed. It is typically installed above the downhole motor but can also be used independently in other downhole assemblies where its functions are required. The assembly is designed to operate reliably under the high pressures and temperatures commonly encountered in deep oil and gas wells.

The MHA includes dual check flapper valves that prevent well fluids from flowing back into the assembly or the coiled tubing, protecting both the equipment and the wellbore. It also incorporates a hydraulic emergency disconnect (HDI), which allows the coiled tubing and tool string to be safely separated if the tool becomes stuck. The disconnect is activated by dropping a metal ball from the surface into the release seat. When pressure reaches a predetermined level, the pins shear and the assembly separates, allowing safe retrieval of the coiled tubing. In addition, the assembly features a circulation valve that allows fluids to flow through the coiled tubing into the annulus, helping to flush and clean the wellbore. A rupture disc within the circulation valve ensures that circulation can be established even if normal flow is blocked.

The Coiled Tubing Motorhead Assembly is engineered for durability and operational safety. It is compatible with coiled tubing sizes ranging from 42.9 mm to 73.0 mm in maximum outer diameter and 11.1 mm to 17.5 mm in minimum inner diameter. Activation ball sizes for the hydraulic disconnect range from 15.9 mm (0.625") to 22.2 mm (0.875"), while the dual check system uses balls ranging from 12.7 mm (0.500") to 19.1 mm (0.750"). The assembly can be connected using standard threads, including 1.0" AMMT, 1.5" AMMT, and 2-3/8" PAC, ensuring compatibility with a wide range of coiled tubing and downhole tools.

The flow paths in the assembly are designed to allow fluids to move freely while protecting the valves and other components from erosion and damage, ensuring long-term reliability. The combination of check valves, hydraulic disconnect, and circulation valve provides multiple layers of safety and control, reducing the risk of damage to the wellbore or equipment during intervention operations.

Engineering Data

More supplies and gear

Reference Information