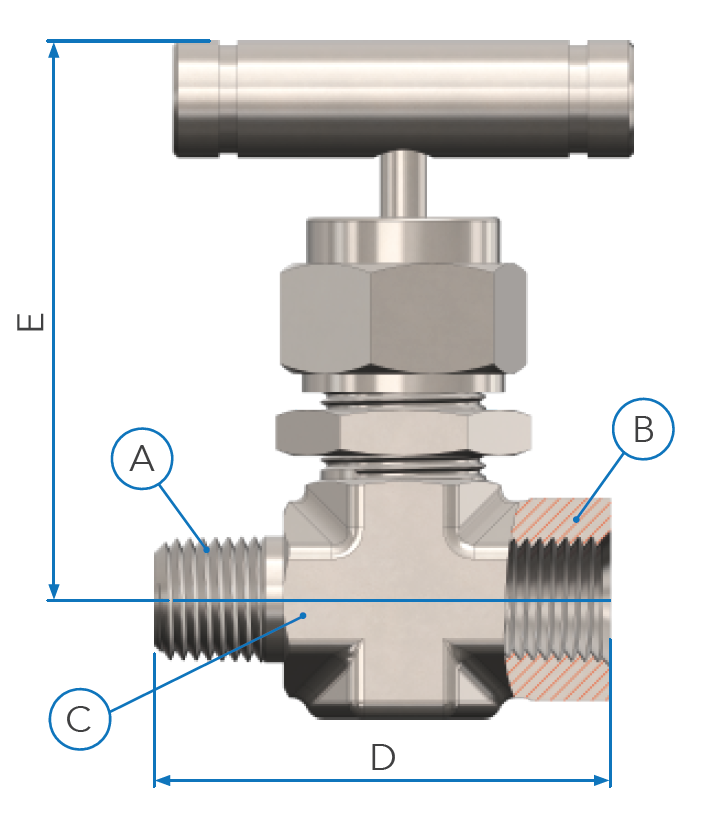

Needle Valves Integral Bonnet Series – Male x Female – 6000 PSI – ASME B16.34 / MSS-SP-99 / ASME B31.3

Needle Valve

Also known as:

Plunger Valve

Needle Valves Integral Bonnet Series – Male x Female – 6000 PSI – ASME B16.34 / MSS-SP-99 / ASME B31.3

Needle Valve

Also known as:

Plunger ValveBuy

In Stock

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

6 - 8 WeeksNote:

Needle Valves Integral Bonnet Series – Male x Female offer leak-free flow control with low torque operation, smooth long-life stems, and a self-centering tip for consistent shut-off.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

The Needle Valves Integral Bonnet Series – Male x Female feature a one-piece body design where the bonnet and body are integrated, eliminating welds and enhancing strength and safety. The Male x Female connection allows easy installation into piping systems, with the male end threading into a female port. These valves are used in oil and gas applications to precisely control and isolate fluid flow, providing reliable, leak-free operation even under high pressure and demanding conditions.

Technical Specifications

| Body Style | Integral Bonnet Series |

| Connections | Male x Female NPT |

| Body Bonnet Seal | Metal to Metal |

| Standard | ASME B16.34 |

| Valve Ratings | ASME B31.3 Process Piping Code |

| Type Tested | MSS-SP-99 |

| Standard Working Pressure | 6000 PSI |

| Dust Protection | Dust cap on stem |

| Handle | Removable T-handle for low torque operation |

| Temperature Rating | -50°C to 230°C |

Features and Benefits

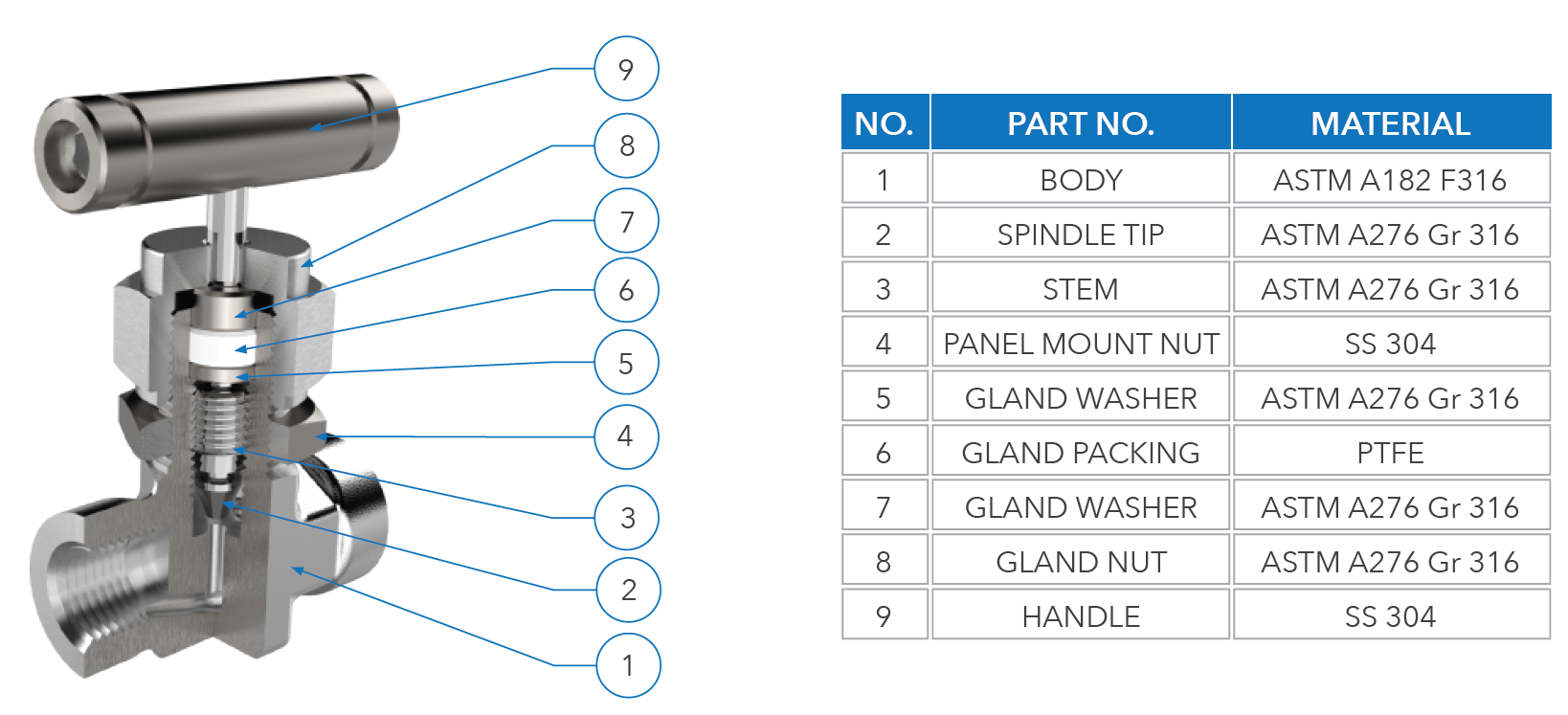

- Removable T Handle aids proper actuation.

- Low torque operation.

- Fully supported packing reduces need for adjustment.

- Rolled stem threads for smooth acting, strength and long life.

- One-piece construction no welding used – For high strength and safety.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The Needle Valves Integral Bonnet Series – Male x Female is designed for reliable and precise flow control in industrial applications, particularly in oil and gas. Its integral bonnet construction means the body and bonnet are a single piece, eliminating welds and enhancing overall strength, safety, and durability. This design ensures consistent performance under high-pressure conditions and reduces the risk of leakage or mechanical failure.

The Male x Female configuration allows for straightforward installation into piping systems, with the male end threading securely into a female port. This connection type is widely used in process lines, instrumentation, and control systems where accurate flow adjustment, isolation, or sampling is required.

These valves feature a removable T-handle for easy actuation with low torque, rolled stem threads for smooth operation and long service life, and fully supported packing to minimize maintenance. A self-centering, non-rotating stem tip ensures bubble-tight shutoff, while the mirror-finished stem reduces wear on packing and facilitates smooth operation. Optional stellite-tipped stems are available for applications involving abrasive or corrosive fluids, further extending the valve’s lifespan.

This series is ideal for applications requiring precise flow control, reliable sealing, and long-term durability in harsh environments such as high-pressure oil and gas systems, chemical process lines, and instrumentation panels.

Engineering Data

More supplies and gear

Reference Information