Check Valve Poppet Type – Male x Female 3/8" NPT – 6000 PSI – ISO 9001

Check Valve

Also known as:

Non-return Valve, One-way Valve, Reflux Valve, Retention Valve

Check Valve Poppet Type – Male x Female 3/8" NPT – 6000 PSI – ISO 9001

Check Valve

Also known as:

Non-return Valve, One-way Valve, Reflux Valve, Retention ValveBuy

In Stock

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

6 - 8 WeeksNote:

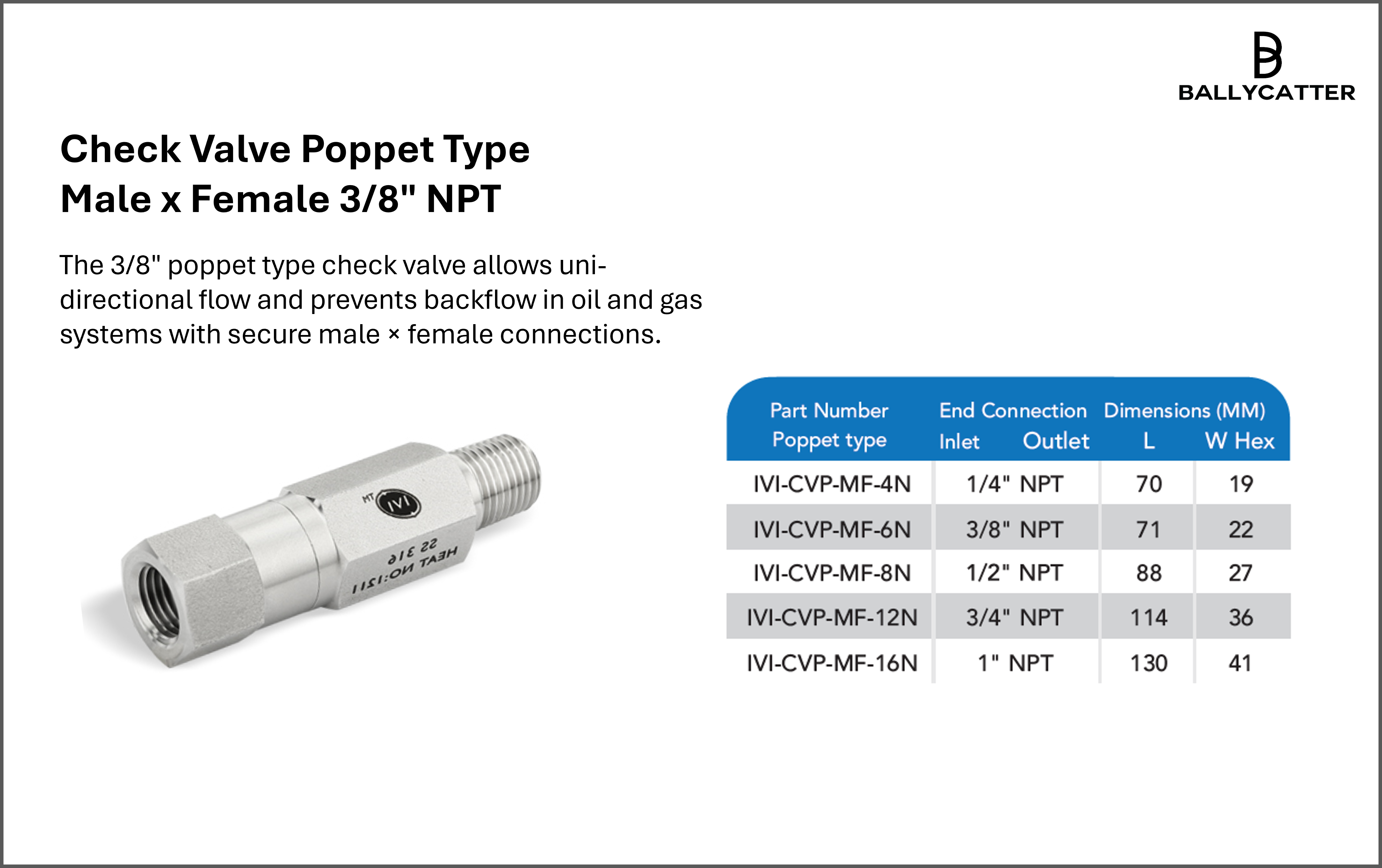

The 3/8" poppet type check valve allows uni-directional flow and prevents backflow in oil and gas systems with secure male × female connections.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

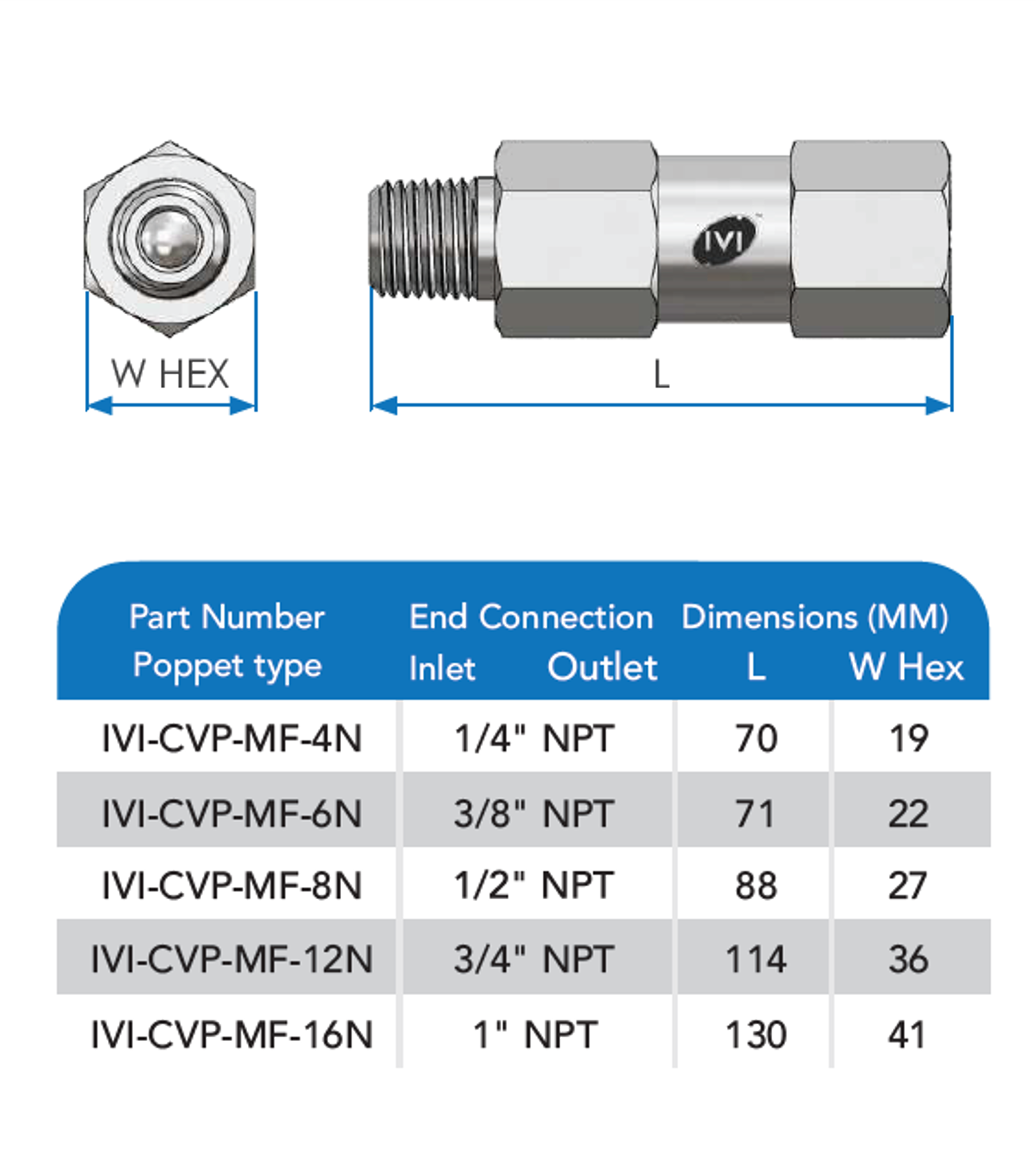

The 3/8" poppet type check valve allows fluid to flow in one direction while preventing backflow in oil and gas systems. Its design provides fast response and reliable sealing under pressure. Male x female NPT connections enable secure inline installation and easy integration into existing piping. The valve is suitable for instrumentation, sampling, control lines, and small to medium diameter pipelines.

Technical Specifications

| End Connection | Male x Female NPT |

| Size | 3/8" |

| Flow Direction | Uni-directional |

| Standard Working Pressure | 6000 PSI |

| Maximum Working Pressure | 10000 PSI (on request) |

| Cracking Pressure | 1/3 to 25 PSI |

| Temperature Rating | –40 °F to 450 °F (–40 °C to 232 °C) |

| Materials | SS 316, Brass, Monel 400 |

| Installation | Inline or panel-mounted integration possible |

| Valve Type | Poppet Check Valve |

Features and Benefits

- Uni-directional flow to prevent backflow.

- Heat code traceability for material verification.

- Easy integration into existing piping with reduced leak points.

- Provides reliable operation in oil and gas systems.

- Durable and reliable in harsh and demanding oil and gas environments.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The 3/8" poppet type check valve with male × female NPT connections is designed for uni-directional flow control and backflow prevention in oil and gas systems. The poppet mechanism provides fast response to flow changes and a positive seal under pressure, ensuring protection of pipelines, pumps, and equipment from reverse flow or pressure transients.

The 3/8" size is suitable for small to medium diameter lines, instrumentation, sampling, and control applications. Male × female NPT connections allow secure inline installation, reducing potential leak points and enabling integration into existing piping without additional adapters.

The valve has a standard working pressure of 6000 psi, with optional configurations rated up to 10000 psi. Selectable cracking pressures range from 1/3 to 25 psi, allowing precise adjustment for system requirements. Construction materials include corrosion resistant SS 316, SS 316L, Duplex, Super Duplex, Hastelloy C276, Inconel 625, Monel 400, and Brass, providing durability in harsh oil and gas environments.

All valves are factory tested for cracking and reseal performance, with pneumatic testing at 1000 psig to verify seat integrity. Heat code traceability ensures material verification, and additional testing including vibration, temperature, and helium is available for critical applications requiring high reliability.

Engineering Data