Needle Valves Angle Pattern Series – Male x Female – 1/4", 3/8”, 1/2”, 3/4", 1” – 6000 PSI – ASME B16.34 / MSS-SP-99 / ASME B31.3

Needle Valve

Also known as:

Plunger Valve

Needle Valves Angle Pattern Series – Male x Female – 1/4", 3/8”, 1/2”, 3/4", 1” – 6000 PSI – ASME B16.34 / MSS-SP-99 / ASME B31.3

Needle Valve

Also known as:

Plunger ValveBuy

In Stock

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

6 - 8 WeeksNote:

Angle Pattern Needle Valves Male x Female control flow and change direction, with easy male-female connections.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

Angle Pattern Needle Valves Male x Female are used to control and regulate fluid flow in a 90-degree direction. The male-female design allows easy connection to piping systems. They are suitable for high-pressure applications in the oil and gas industry, providing precise flow control and durability.

Technical Specifications

| Body Style | Angle Pattern Series |

| Connections | Male x Female NPT |

| Body Bonnet Seal | Metal to Metal |

| Standard | ASME B16.34 |

| Valve Ratings | ASME B31.3 Process Piping Code |

| Type Tested | MSS-SP-99 |

| Standard Working Pressure | 6000 PSI |

| Dust Protection | Dust cap on stem |

| Handle | Removable T-handle for low torque operation |

| Temperature Rating | -50°C to 230°C |

Features and Benefits

- Angle pattern design for 90° flow change.

- Male x Female connections for flexible installation.

- Removable handle for low torque operation.

- Reliable long-term operation under high pressure.

- Easy to connect to different pipe types and sizes.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

Angle Pattern Needle Valves Male x Female are designed to control the flow of liquids or gases in a piping system. The angle pattern allows the flow to change direction by 90 degrees, reducing piping complexity and minimizing pressure drop.

The male x female configuration enables easy connection to different pipe types and sizes, providing flexibility for installation in various system layouts. These valves are suitable for high-pressure applications, ensuring reliable and leak-free operation.

In oil and gas operations, they are used for controlling flow to instruments, transmitters, or equipment where space is limited and accurate flow control is needed. Metal-to-metal seals and durable stems ensure long-term performance under demanding conditions.

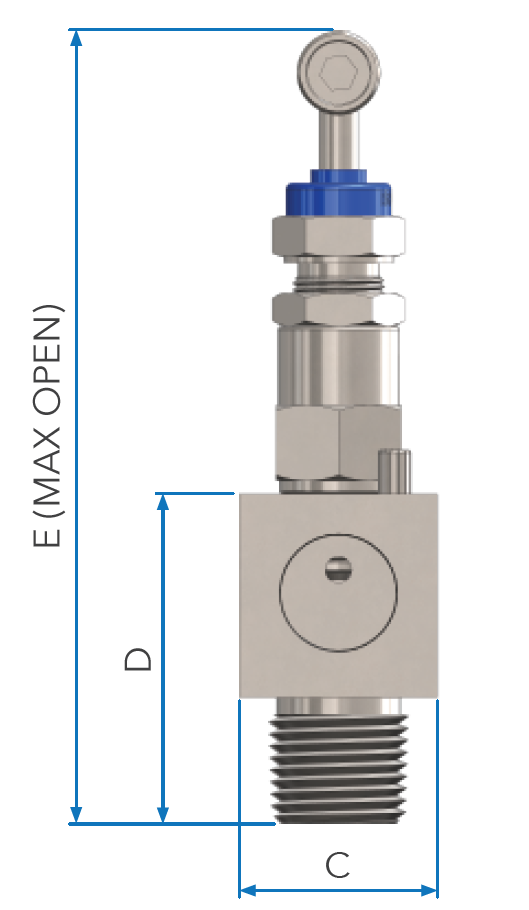

Engineering Data

Technical Support

Ballycatter is an international company active in the oil & gas industry. It is known for providing comprehensive information on a wide range of equipment ...

Ballycatter Delivers Project-Aligned Equipment

Needle Valves Angle Pattern Series – Male x Female – 1/4", 3/8”, 1/2”, 3/4", 1” – 6000 PSI – ASME B16.34 / MSS-SP-99 / ASME B31.3

Ask for more information, deliveries or quote requests.

Ballycatter is an international company active in the oil & gas industry. It is known for providing comprehensive information on a wide range of equipment through its supply portal, Ballycatter.com. The company is headquartered in Alberta, Canada, and maintains a global network of industry contacts across multiple countries.

Overview

Ballycatter supports the industry by offering structured information that matches the way project teams work.

Each equipment listing includes specifications, details in one clear format. This helps to review efficiently. The information is presented in a way that supports assessments and project-fit from the start.

Technical support is available to assist with inquiries regarding equipment specifications and operational considerations. In addition, Ballycatter offers engineering support for who extended needs.

This combination of supply information, technical support and engineering input makes Ballycatter a valuable partner.

Website

Ballycatter.comBallycatter.ca

About Ballycatter

Contact

Service@ballycatter.com+1 (825) 474-4417

Industry

Oil and GasMining

Company size

1-10 employeesHeadquarters

Calgary, AlbertaFounded

2019Specialties

Workover, Process Equipment, Completions, Construction and Drillling.

Request for quotation

Please fill out the form below to request a quotationRequest for Quotation

Have a Question?

Fill out the form — we’ll respond with a clear, detailed answer that fits the project.

Request for Assistance

More supplies and gear

Reference Information