Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

Also known as:

Service

In Stock

Service

New

API

Land Freight

Solutions

Fishing and Retrieval: Providing expert fishing services for the retrieval of lost or stuck equipment.

Comprehensive Pressure Management: Deploying advanced pressure control equipment for a wide range of well conditions.

Geothermal Services: Delivering specialized interventions for the maintenance and performance enhancement of geothermal wells.

Advanced Downhole Operations: Offering sophisticated downhole services, including slickline and wireline interventions.

Environmental and Quality Compliance: Ensuring operations meet stringent environmental and quality standards.

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

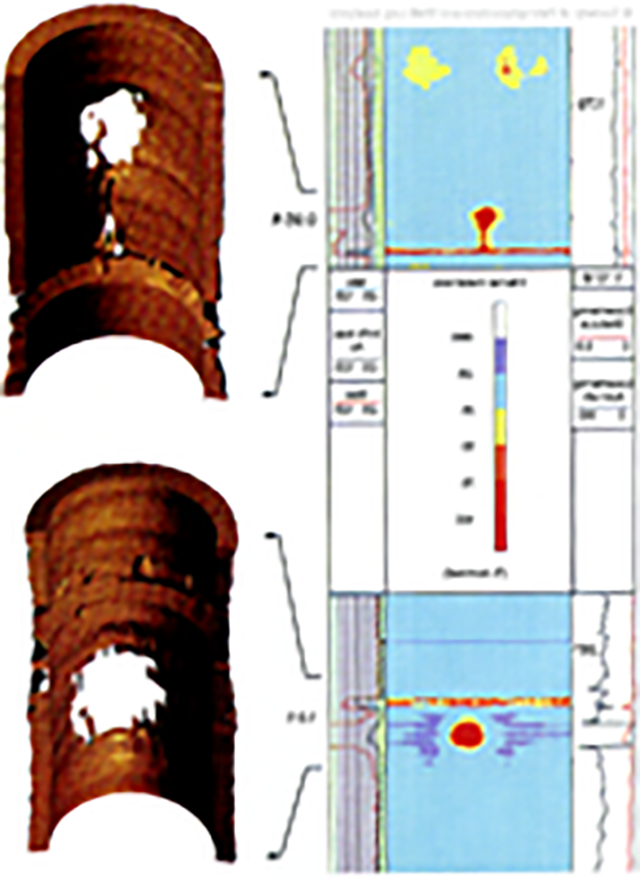

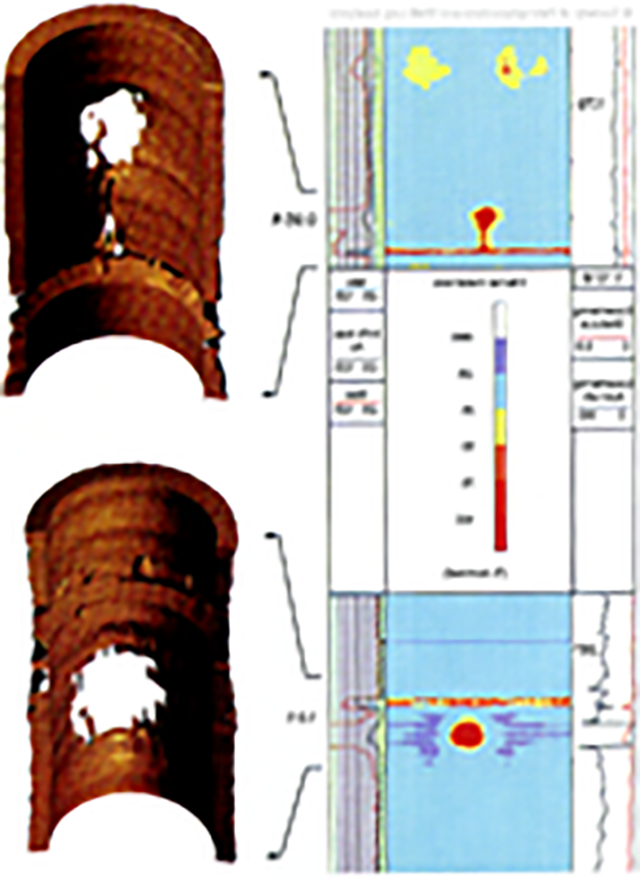

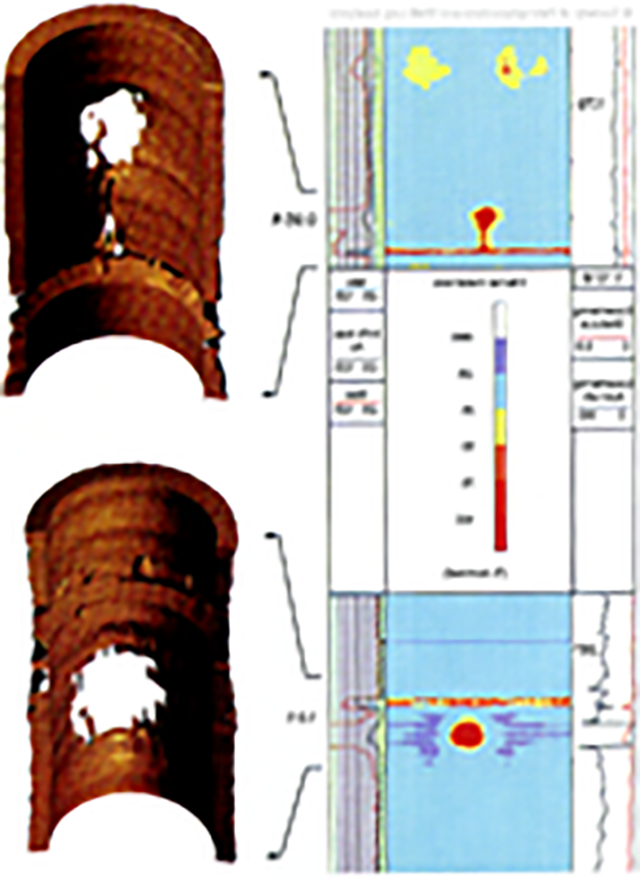

Ensuring Production Integrity with InWaTec Combined's E-Line Tubing Inspection Services In the lifecycle of oil and gas wells, tubing integrity is fundamental to ensuring consistent production and operational safety. At InWaTec Combined, we offer specialized E-Line Tubing Inspection Services to preemptively identify and mitigate risks associated with tubing failure, utilizing state-of-the-art diagnostic techniques to safeguard your assets. Tubing failures, which can stem from deformation, physical wear, or corrosion, pose a significant threat to well integrity and production. Our advanced inspection services are designed to detect these issues early, enabling timely interventions that maintain continuous well performance. Our comprehensive suite of E-Line Tubing Inspection Services includes: Cased-Hole Calipers: These tools provide precise measurements of the internal diameter of tubing, detecting anomalies and changes that could indicate deformation or wear. Flux-Leakage Tools: Specialized for identifying defects in ferrous tubulars, these tools locate areas of metal loss or corrosion by detecting disruptions in magnetic flux. Electromagnetic Phase-Shift Tools: By measuring the changes in electromagnetic fields, these tools can effectively pinpoint areas of wall thickness changes due to corrosion or wear. Ultrasonic Tools: Employing high-frequency sound waves, these tools are adept at measuring tubing wall thickness, identifying areas at risk of thinning, which could lead to potential collapse. In addition to these, our E-Line Tubing Inspection Services also employ ultrasonic radial-cement-evaluation and modified openhole-imaging devices, which are particularly effective in assessing the condition of the tubing for signs of internal or external metal loss—a crucial step in preventing unexpected well shut-ins. At InWaTec Combined, we understand that the stakes are high when it comes to maintaining well integrity. Our E-Line Tubing Inspection Services are not just about identifying problems; they're about delivering peace of mind. By utilizing our advanced diagnostic tools, operators can rest assured that the integrity of their production tubing is being monitored with the utmost precision, allowing them to focus on maximizing output and efficiency. Choosing InWaTec Combined means partnering with a company that places a premium on innovation, safety, and reliability. Our commitment to excellence ensures that your operations benefit from the latest in inspection technology, delivered by a team of seasoned professionals. Trust us to provide the insights you need to keep your wells flowing safely and smoothly, today and into the future.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

InWaTec Combined: Clearing the Path to Performance with Gauge Cutter Services In the intricate arena of subsurface control, the clarity of the pathway is paramount. At InWaTec Combined, we specialize in pre-emptive solutions that pave the way for unimpeded operations. Our Gauge Cutter running services are a critical component of this approach, ensuring that your tubing is verified for freedom from obstruction, thus setting the stage for smooth running or pulling of subsurface controls. The Imperative for a Clear Tubing A gauge cutter is an essential tool in the well servicing toolkit. Its primary role is to confirm that the tubing through which subsurface controls will be run is clear of any blockages. InWaTec Combined’s gauge cutter services provide operators with the assurance they need before commencing critical operations. This step is not just precautionary; it is a strategic move to avoid non-productive time and to ensure that all subsequent interventions are conducted efficiently and effectively. The Gauge Cutter Advantage The design of our gauge cutters is a product of extensive research and practical field experience. The bottom shape of our tools is meticulously crafted to scratch, jar, and cut away common wellbore obstructions like paraffin, sand, or other deposits from the tubing wall. This cleaning action may necessitate several runs with gauge cutters of varying sizes, a process InWaTec Combined is well-equipped to manage. Versatile Applications for Comprehensive Assurance Our gauge cutter services are versatile and comprehensive. Often used to tag the top of landing nipples, Sliding Sleeve Doors (SSDs), or to ascertain the total well depth, our tools provide operators with a multi-faceted solution. Whether it’s for routine maintenance or critical well interventions, running a gauge cutter is a step that can save time and resources in the long run. Customized to Well Specifications Understanding that each well has its unique challenges, InWaTec Combined offers gauge cutters in various sizes and configurations. This customization allows for tailored applications, ensuring that whether the obstruction is due to paraffin buildup or sand deposition, we have the right tool for the job. Commitment to Operational Continuity Choosing InWaTec Combined for your gauge cutter services means selecting a partner dedicated to your operational continuity. Our tools and techniques are designed to facilitate a clear and smooth path for your subsurface controls, minimizing the risks of unexpected interruptions and maximizing your operation's productivity. A Clear Path Forward In summary, InWaTec Combined’s Gauge Cutter running services are an indispensable part of ensuring a successful and uninterrupted operation. By removing potential obstructions and verifying well integrity, we help you maintain operational efficiency. Trust InWaTec Combined to clear the path for your well’s performance, ensuring that every operation from the surface to the subsurface is conducted with confidence and precision.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Ensuring Continuity with InWaTec Combined’s Electric Line Pipe Recovery Services In the dynamic arena of oil and gas extraction, the unexpected is the only constant. One of the most formidable challenges that can grind operations to a halt is the dreaded scenario of a stuck drill string. Recognizing the critical need for swift and effective resolution, InWaTec Combined offers specialized Electric Line Pipe Recovery Services, designed to address and rectify such downhole dilemmas. When a drill string becomes lodged downhole, it is not just an obstacle; it represents a halt in production, potential damage to resources, and a significant operational cost. InWaTec Combined's Electric Line Pipe Recovery Services are the answer to this industry-wide challenge. Our services employ advanced wireline technology, leveraging the power of electric lines to deliver targeted interventions that free the stuck pipe. Our approach to pipe recovery combines precision-engineered tools with real-time data transmission capabilities. This dual advantage enables our skilled operators to assess the situation accurately and execute recovery procedures with minimal risk to the wellbore or the environment. By integrating our electric line expertise with our pipe recovery operations, we ensure that your drill rig can return to its primary function with minimal downtime. The electric lines play a crucial role; they not only serve as a conduit for the necessary tools to navigate the wellbore but also provide a continuous stream of data back to the surface. This data is critical for making informed decisions during the recovery process, allowing for adjustments and interventions that are precise and situation-specific. At InWaTec Combined, we understand that time is of the essence in such operations. Our Electric Line Pipe Recovery Services are designed for rapid deployment and execution, ensuring that your operations can swiftly transition from a state of suspension to full productivity. Our commitment to innovation, safety, and efficiency is unwavering, as we strive to provide solutions that minimize operational disruptions and maintain the integrity of your wellbore. In the face of stuck pipe challenges, you can count on InWaTec Combined to deliver not just services, but solutions that propel your operations forward. Trust in our expertise to navigate the complexities of downhole recovery, ensuring that your operations remain resilient and robust, no matter what obstacles lie beneath.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

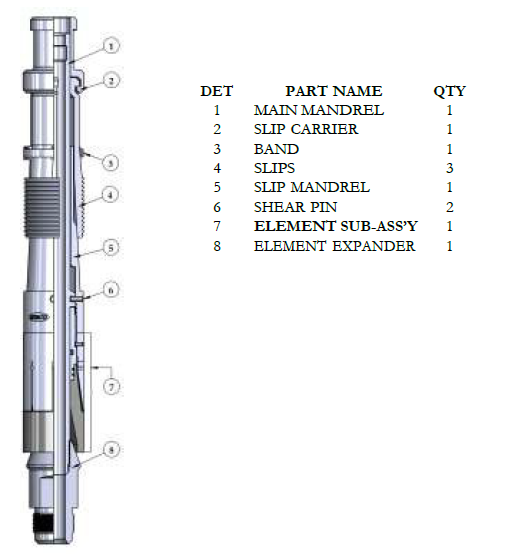

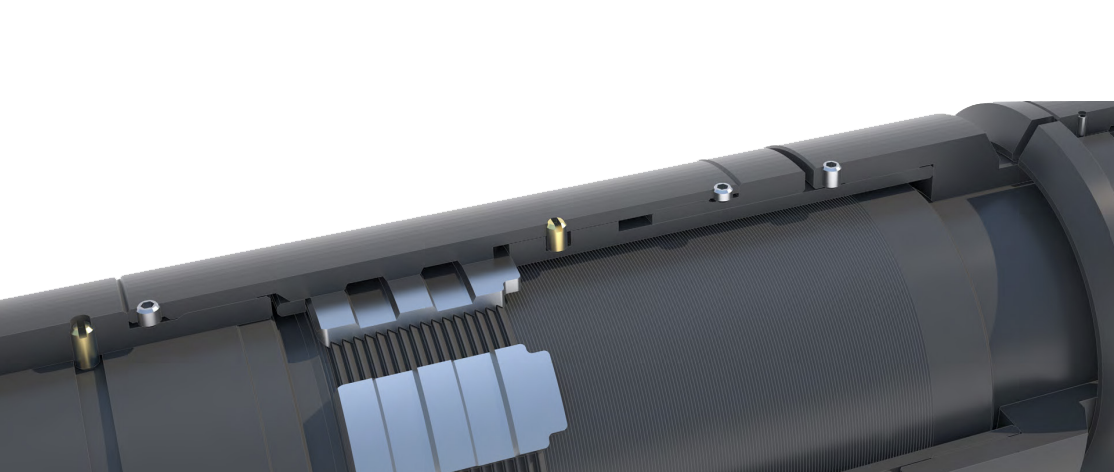

Enhancing Well Efficiency: InWaTec Combined’s Precision E-line Packer Setting Services The backbone of any well’s structural integrity and operational efficiency lies in the strategic placement and setting of production packers. InWaTec Combined’s E-line Packer Setting Services provide meticulous installation of these critical components, ensuring an optimal seal and isolation within your wellbore. A production packer is not just a piece of hardware; it’s a guardian that ensures the separation of production zones, safeguards the casing from pressure, and enhances the overall management of the well. Our E-line Packer Setting Services cater to both production and service packer requirements, providing versatile solutions tailored to the unique challenges of your well operations. Production Packers: These remain in place during well production, set above the top perforations or sand screens. They are pivotal in multi-zone reservoirs, where they isolate perforations for each zone, allowing for selective production through the use of sliding sleeves. Service Packers: Employed temporarily during well servicing tasks like cement squeezing, acidizing, fracturing, and well testing, service packers are essential for the precise and safe execution of these operations. Packers are designed with a keen eye on reliability—metal slips and rubber elements, or metal rings in high-pressure scenarios, ensure a firm grip and seal against the casing ID. Our E-line Packer Setting Services employ the latest in axial load technology, whether hydraulic, mechanical, or chemical, to expand and secure these packers at the optimal depth. For permanent well configurations, our permanent packers offer a cost-effective and robust solution, boasting superior sealing and gripping capabilities. When retrievability is key, our retrievable packers provide flexibility for secondary recoveries, re-completions, or production tubing changes, with designs that ensure ease of removal and the possibility of reuse after servicing. InWaTec Combined’s commitment to excellence in E-line Packer Setting Services is unwavering. We provide not only the tools but also the strategic foresight and technical support to ensure that your packer installation enhances well performance, maintains integrity, and supports your production goals. Partner with InWaTec Combined for your packer setting needs and experience the assurance that comes from precision, durability, and adaptability. Our services are designed to secure your well’s future, one packer at a time.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Retrieving Success: InWaTec Combined’s Expert Wireline Fishing Tool Services In the demanding environment of well intervention, the unforeseen loss of equipment downhole is a challenge that operators must be prepared to address promptly and efficiently. InWaTec Combined's Wireline Fishing Tool Services are the epitome of precision and reliability, providing a lifeline when well intervention tools or other equipment become unintended tenants of the wellbore. Our Wireline Fishing Tool Services are designed for success, equipped with a full spectrum of specialized mechanical tools that offer a robust solution for retrieval operations. The expertise behind our services is matched by the quality and variety of tools in our standard fishing toolbox, including: Wireline Clamp: A vital tool for securing and retrieving wireline equipment, ensuring that no further slipping occurs during retrieval operations. Wireline Grab: Our grabs are adept at latching onto equipment, providing a firm grip that is essential for the successful extraction of fallen tools. Wireline Finder: A precision instrument that aids in locating lost equipment within the wellbore, ensuring that our operations are targeted and effective. Overshots: These tools are designed to fit over and engage with the fish, facilitating an efficient recovery process. Tubular Jars: Employed to deliver impacts to dislodge stuck equipment, our jars are selected for their reliability and force-delivery precision. Heavy Duty Pulling Tool: For items that require significant force for retrieval, our heavy-duty pulling tools are up to the task, combining strength with control. Wireline Cutters: When the situation calls for severing wireline or other materials to free the fish, our cutters are engineered to slice through with minimal fuss. At InWaTec Combined, we understand that every fishing operation presents its own set of challenges. That's why our services are not only comprehensive but also customizable. We analyze the specifics of each fishing scenario and select the appropriate tools from our toolbox to ensure a successful outcome. Our team of well intervention specialists is highly trained and experienced, ready to deploy at a moment's notice to address your fishing needs. With InWaTec Combined's Wireline Fishing Tool Services, you gain more than just a service provider; you gain a partner who is as invested in the success of your operations as you are. Choose InWaTec Combined for your wireline fishing tool needs and experience the peace of mind that comes from knowing that you have the best in the business on your side. Let us help you turn setbacks into success stories with our expert fishing tool services—because in the world of well intervention, the right retrieval is everything.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

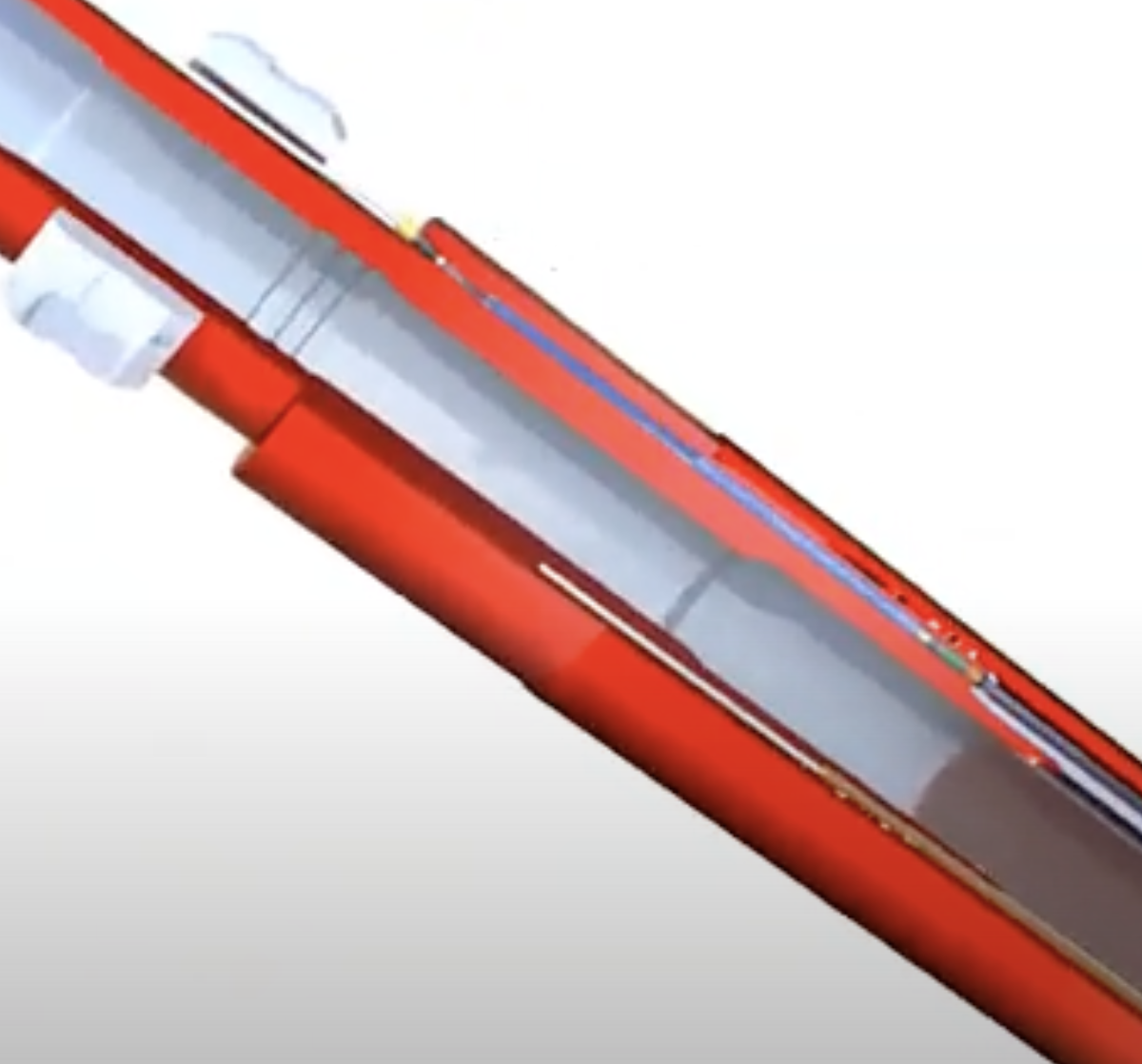

Seamless Zone Isolation: InWaTec Combined’s E-line Bridge Plug Setting Services In the complex operations of oil and gas extraction, the ability to isolate zones within the wellbore is critical for effective production management and intervention. InWaTec Combined offers specialized E-line Bridge Plug Setting Services, utilizing state-of-the-art tools to achieve precise zonal isolation with both permanent and retrievable bridge plug options. Bridge plugs are essential elements in completion hardware, designed to provide robust seals both above and below the production tubing within the casing, liner, or wellbore wall. Their primary function is to isolate certain sections of the well, which is especially beneficial in wells with multiple producing zones or when specific zones need to be temporarily sealed off during interventions. Permanent Bridge Plugs: These are typically favored for their cost-effectiveness and superior sealing and gripping capabilities. Once set, they provide a dependable barrier, with metal slips or "slips" that anchor into the casing's inner diameter using sharpened, carburized teeth. The seal is completed with large cylindrical rubber elements, and in high-pressure environments, metal rings enhance the seal by preventing rubber extrusion. Retrievable Bridge Plugs: These plugs are the go-to solution when flexibility is required, such as during secondary recovery operations, well re-completions, or when there's a need to change out production tubing. Though they may have lower sealing and gripping capabilities compared to permanent options, their design allows for removal and reuse, providing significant operational versatility. Our E-line Bridge Plug Setting Services deploy these tools with precision. The plug is conveyed into the well via wireline—a method that provides real-time depth control and selectivity. Once at the target depth, an axial load is applied to the bridge plug to initiate the expansion of the slips and rubber elements, creating a secure seal against the casing. The setting mechanism can be activated hydraulically, mechanically, or with a controlled chemical charge, depending on the well conditions and client requirements. InWaTec Combined’s expertise ensures that the most appropriate setting method is chosen for each operation, considering the well's pressure environment, the desired duration of the plug setting, and the future plans for the well. By opting for InWaTec Combined’s E-line Bridge Plug Setting Services, operators benefit from a service that combines reliability with adaptability. Our commitment to leveraging advanced technologies with expert execution means that your well operations can proceed with confidence, knowing that each zone is isolated with the utmost precision. InWaTec Combined is dedicated to providing solutions that enhance operational efficiency and well integrity. Whether you require a permanent solution for long-term isolation or the flexibility of a retrievable plug for short-term interventions, our E-line Bridge Plug Setting Services are designed to meet your needs with precision, reliability, and cost-effectiveness.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Optimizing Reservoir Connectivity with InWaTec Combined's Precision Perforating Services In the intricate execution of oil and gas production, establishing a seamless flow path between the reservoir and the wellbore is vital for optimal extraction. At InWaTec Combined, we specialize in precision Perforating Services, a critical step towards ensuring that our clients’ wells are prolific producers. Perforating is a sophisticated process, and its execution is both an art and a science. It involves the precise creation of holes from the wellbore through the casing and cement sheath directly into the producing zone. This process is not merely about making openings; it's about strategically placing them to maximize flow rates and enhance the recovery of hydrocarbons. Our approach to perforating is methodical and tailored. We begin with an in-depth analysis of the well conditions and reservoir characteristics. This data informs our selection of perforating techniques, which range from the conventional to the cutting-edge, including shaped charges and advanced explosive materials that create clean, deep perforations with minimal damage to the formation. InWaTec Combined’s Perforating Services are about more than just punching holes; they are about delivering a highly controlled and effective conduit for hydrocarbons to travel from the reservoir to the surface. With our state-of-the-art technology and expertly engineered charges, we can ensure that the flow path is not just established, but optimized for the specific conditions of each well. Safety and precision are at the heart of our operations. We employ the latest in downhole technology, including real-time monitoring and electric line conveyance, to ensure that our perforations are executed with the highest degree of accuracy and control. This commitment to excellence and attention to detail is why InWaTec Combined is a leader in the field. By entrusting InWaTec Combined with your perforating needs, you are not just choosing a service provider—you are choosing a partner dedicated to enhancing the productivity of your wells. Our Perforating Services are integral to preparing your wellbore to be a strong link between the hidden riches of the reservoir and the energy needs of the world. Let us bring our expertise and precision to bear on your operations, and together, we can unlock the full potential of your assets.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

InWaTec Combined: Pinpoint Precision with Tubing End Locator Services Accuracy is the cornerstone of successful well intervention and maintenance operations, and InWaTec Combined’s Tubing End Locator (TEL) running services exemplify this precision. Our TEL services provide clients with the certainty needed for depth correlation and critical downhole positioning, ensuring that all subsequent interventions are executed with pinpoint accuracy. The Crucial Role of the Tubing End Locator The TEL is an invaluable tool in the oil and gas industry’s arsenal, designed to accurately locate the end of the tubing string. This precise location is essential for depth correlation during various well servicing operations. InWaTec Combined's TEL services ensure that your team has the exact measurements necessary for efficient and effective intervention planning. Preparation for Precision Before deploying the TEL, it's crucial to ensure the tubing is clear of any debris that could obstruct the locator. InWaTec Combined’s preparatory procedures, which include running a gauge cutter or bailer, are meticulous steps that guarantee the TEL can smoothly navigate to and through the end of the tubing. This thorough clearing is part of our commitment to precision – we ensure that when the TEL is deployed, it operates in an unimpeded environment. Adaptable and Versatile Tooling Our TELs are equipped with a spring-loaded finger, enabling them to be run in various tubing sizes, ranging from 2-3/8? to 5-1/2?. This adaptability makes InWaTec Combined’s TEL services universally applicable, providing versatility without compromising on the accuracy of the tool. Whatever the tubing size, our TEL services can be tailored to meet the specific needs of the operation. Streamlining Operations with Accurate Measurements The accuracy provided by our TEL services streamlines subsequent operations by providing a reliable reference point. This eliminates guesswork, reduces the risk of error, and enhances the efficiency of operations such as setting packers, plugs, or perforating at precise depths. InWaTec Combined’s Promise of Excellence At InWaTec Combined, we understand the impact that accurate depth measurements can have on the success of well operations. Our TEL running services are a reflection of our promise to deliver excellence in every aspect of our work. We provide not just a service, but a partnership that enhances and ensures the precision of your well servicing tasks. Conclusion: Your Partner in Depth Correlation In conclusion, InWaTec Combined’s Tubing End Locator services are crucial for any operation that demands exact depth measurements. With our state-of-the-art tools and meticulous preparation, we ensure that every intervention is carried out with the confidence that comes from knowing the exact parameters of your well. Partner with InWaTec Combined, where precision is not just a metric; it's a mission.

Rental

In Stock

Product

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

InWaTec Combined: Streamlining Wellbore Clarity with Premier Sample Bailer Services In the ever-evolving landscape of drilling and production, the importance of maintaining a clean wellbore is paramount. At InWaTec Combined, we understand that the efficiency of your operations hinges on the clarity of the wellbore. That's why we offer comprehensive Sample Bailer running services, designed to support operations on drilling rigs, during workover operations, and in production wells, whether onshore or offshore. Optimizing Wellbore Integrity with Bailing Operations Bailing operations are a critical component of wellbore maintenance, aimed at collecting solids and cleaning the wellbore to ensure uninterrupted operations. InWaTec Combined's Sample Bailer services are tailored to meet the needs of any operation, providing a thorough cleansing of the wellbore and collection of solids that could otherwise impede production or damage equipment. Adaptable Services for Diverse Environments Whether it's the dynamic environment of offshore rigs or the structured demands of onshore wells, InWaTec Combined's Sample Bailer services are adaptable to any setting. Our equipment and expertise are suited to the unique challenges presented by both drilling and production phases, ensuring that we provide optimal solutions regardless of the environment. Leveraging Technology for Efficient Operations At InWaTec Combined, we utilize the latest technology in our Sample Bailer running services. This approach allows us to efficiently collect wellbore debris and samples, minimizing downtime and maximizing the productivity of the well. Our commitment to technological advancement means that we continuously improve our services to stay at the forefront of the industry. Safety and Environmental Stewardship We prioritize safety and environmental stewardship in all our operations. Our Sample Bailer services are conducted with strict adherence to safety protocols, ensuring the well-being of personnel and the preservation of the environment. We understand the importance of eco-friendly operations, especially in sensitive onshore and offshore locations. InWaTec Combined’s Commitment to Excellence Choosing InWaTec Combined for your bailing needs means partnering with a company that is committed to excellence. Our Sample Bailer running services are designed to deliver results with precision, safety, and environmental responsibility at the forefront. We are dedicated to providing services that not only meet but exceed industry standards. Conclusion: Your Clear Choice for Clear Wells In summary, InWaTec Combined’s Sample Bailer running services represent the highest standard in wellbore cleaning and sample collection. With our advanced technology, adaptable services, and unwavering commitment to safety and the environment, we are your clear choice for ensuring the integrity and productivity of your wells. Trust InWaTec Combined to deliver clarity and quality to your wellbore operations.

Service

In Stock

Service

New

API

Land Freight

Offshore Electric Line Services

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Navigating the Depths: InWaTec Combined's Advanced Offshore E-Line Services In the challenging and complex world of offshore operations, precise and dependable wellbore data transmission is not just beneficial—it's crucial. At InWaTec Combined, our Offshore Electric Line (E-Line) services are the cornerstone of our well diagnostics and intervention solutions, designed to conquer the unique demands of the offshore environment. An E-Line, in its simplest form, is a robust electric cable. Yet, when deployed by InWaTec Combined, it becomes an integral part of offshore operations, a sophisticated tool that delves into the wellbore's mysterious realms. Our E-Line services excel in transmitting real-time data about the wellbore's conditions back to our offshore experts, ensuring that critical decisions are made with the utmost information at hand. Our E-Line's forte lies in its versatility and utility in conducting a plethora of logging activities essential for evaluating the well's integrity, formation properties, and hydrocarbon potential. These activities enable a comprehensive understanding of the well, providing insights necessary for optimizing production and ensuring the safety of offshore operations. The offshore environment poses unique challenges with its unpredictable nature and the sheer scale of operations. InWaTec Combined's E-Line services are designed to be resilient and adaptable, capable of withstanding the high pressures and corrosive elements found in the deep sea. Our commitment to innovation means that our E-Line technology is continuously evolving, pushing the boundaries of what is possible in offshore data gathering. By choosing InWaTec Combined's Offshore E-Line services, our clients receive more than just data—they gain a strategic advantage. With our advanced technology and expert analysis, we provide the insights necessary to maximize well performance, extend the life of offshore assets, and enhance the overall safety and efficiency of offshore operations. In an industry where the margin for error is slim and the consequences significant, InWaTec Combined stands as a beacon of reliability and excellence. Our Offshore E-Line services are not just a component of your operations—they are a pivotal part of your success story, deep beneath the waves.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

InWaTec Combined: Capturing Downhole Details with Precision Lead Impression Block Services In the realm of well intervention and remediation, knowledge is power. InWaTec Combined elevates this concept to new heights with our Lead Impression Block (LIB) running services, a pivotal tool in the 'fishing' operations toolkit. The LIB is not just an instrument; it's your eyes beneath the surface, providing crucial information that guides subsequent operations. Unveiling the Subsurface Mysteries At the core of our LIB service is a lead-filled cylinder, meticulously secured with pins within its body, designed to make a perfect impression of the downhole equipment, also known as "the fish." When retrieval operations are underway, knowing the exact shape, size, and condition of the fish is invaluable. This is where our LIB service shines, delivering a precise imprint of the obstruction, which becomes the blueprint for planning the recovery strategy. Tailored Weight Control for Precision Impressions The success of an impression block operation hinges on the precise control of the weight applied to it. InWaTec Combined's slickline units are equipped with sophisticated weight control mechanisms, allowing our skilled operators to lower the LIB into the wellbore with the exact amount of force needed to capture an accurate replica of the downhole situation. The Key to Efficient Fishing Operations Understanding what lies beneath the surface dictates the efficiency of the entire fishing operation. With the impression from our LIB, operators can ascertain not only the size and shape of the fish but also the appropriate tools and techniques needed for the next step. This preemptive intelligence minimizes trial and error, saves valuable time, and ensures that the chosen extraction method has the highest chance of success. A Foundation for Informed Decisions The intelligence gathered by the LIB is a critical asset in the decision-making process. InWaTec Combined prides itself on providing clients with detailed downhole data, enabling a strategic approach to fishing operations. The clarity provided by our LIB service means less downtime, fewer uncertainties, and a streamlined path to operational continuation. Your Partner in Downhole Clarity InWaTec Combined is not just a service provider but a partner in your well servicing endeavors. We bring not only the technology but also the expertise and experience to ensure that your fishing operations are based on the most accurate downhole information available. Conclusion: Precision Leads the Way In conclusion, the Lead Impression Block running services offered by InWaTec Combined are more than just a procedural step; they are a cornerstone of informed intervention. By enabling a precise understanding of the downhole environment, we empower operators to act with confidence and precision, ensuring the success of subsequent operations and the overall productivity of the well. Trust InWaTec Combined to deliver a clear picture of the challenges and the solutions beneath the surface.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Enhancing Snubbing Operations: InWaTec Combined’s High-Pressure Mini-Coil Services At InWaTec Combined, we understand the critical nature of snubbing operations in well intervention and maintenance. Our Mini-Coil Tubing services are specifically designed to enhance these operations, providing a solution that balances the delicate requirements of fluid placement and well lifting with the necessity for high-pressure performance. Optimal Fluid Placement: The Mini-Coil Tubing is adept at delivering small quantities of fluids precisely where they are needed. This precise placement is particularly beneficial during snubbing operations, where control and accuracy are paramount to successful well control and intervention. Efficient Well Lifting: When it comes to lifting wells into production, especially during snubbing operations, our Mini-Coil Tubing shines with its ability to handle high pumping pressures. This capability ensures that wells are brought into production efficiently and reliably. High-Pressure Operations: While Mini-Coil Tubing may face limitations in flow rate and mechanical snubbing force due to its smaller size, it compensates with an exceptional capacity for withstanding higher pumping pressures. This makes it particularly useful in situations where pressure integrity is crucial. The nature of snubbing operations often involves dealing with wells under pressure. The high-pressure resistance of our Mini-Coil Tubing means it can be deployed in environments that are too challenging for larger, conventional coiled tubing. This feature opens up new possibilities for conducting critical well interventions safely and effectively. InWaTec Combined's Mini-Coil Services are not just about providing equipment; they're about delivering a comprehensive solution. We understand that each well and operation has its unique set of challenges. Our Mini-Coil Tubing services are complemented by a team of experienced professionals who ensure that every operation is executed with precision, efficiency, and adherence to the highest safety standards. Customized Solutions: Recognizing the unique demands of each operation, InWaTec Combined offers customized Mini-Coil solutions. We work closely with clients to understand their specific needs and challenges, ensuring our Mini-Coil Tubing services are tailored to meet the particular requirements of their snubbing operations. Choose InWaTec Combined for your snubbing operation needs, and benefit from the advanced performance of our Mini-Coil Tubing services. Our commitment to innovation, safety, and operational excellence ensures your operations are not just maintained but enhanced. Let us help you achieve your well intervention goals with our high-pressure, precision-driven Mini-Coil services.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Revolutionizing Geothermal Well Interventions: InWaTec Combined's Mini-Coil Services In the dynamic world of geothermal energy production, where the efficient management of well interventions is paramount, InWaTec Combined is pioneering with our Mini-Coil Services. Designed to navigate the unique challenges of geothermal wells, our Mini-Coil Tubing offers a versatile and high-pressure tolerant solution for fluid placements and well stimulation. Geothermal wells demand a delicate balance between precision and strength. Our Mini-Coiled Tubing services are tailored to meet these needs, providing an ideal solution for the small quantity placements of fluids that are often required in geothermal operations. Whether it's for precision acidizing, scale removal, or other chemical treatments, the Mini-Coil is an invaluable tool. Compact Power: Our Mini-Coiled Tubing is compact yet robust, designed to handle the high pumping pressures needed for effective interventions in geothermal wells. Its smaller diameter does not compromise its ability to withstand intense conditions underground. Efficiency in Production: Lifting wells into production efficiently is crucial for maintaining the economic viability of geothermal operations. The Mini-Coil facilitates this by enabling operators to deliver targeted treatments and interventions that can revitalize well performance. Tailored to Geothermal Needs: While traditional coiled tubing operations may be limited by flow and snubbing capabilities, our Mini-Coil Tubing is engineered to overcome these constraints, providing enhanced pressure handling that is especially beneficial in the high-temperature, high-pressure environments characteristic of geothermal wells. It's true that Mini-Coil Tubing has its limitations regarding flow and snub, but what it offers in return is the capacity to handle significantly higher pumping pressures. This attribute is particularly advantageous in geothermal applications where the subsurface conditions can be extreme. InWaTec Combined's commitment to innovation is further demonstrated by the integration of advanced monitoring technologies that accompany our Mini-Coil Services. Real-time data acquisition allows for precise control and assessment of the intervention process, ensuring that operations are not only successful but also conducted with an emphasis on safety and sustainability. In the realm of geothermal energy, where the right interventions can drastically enhance the output and longevity of wells, InWaTec Combined's Mini-Coil Services emerge as a clear choice for operators seeking to optimize their wells. Our services are a testament to our dedication to providing solutions that are both efficient and effective, reducing downtime and maximizing production. Partner with InWaTec Combined for your geothermal well needs and experience the next level of well intervention services. Let our Mini-Coil Tubing unlock the full potential of your geothermal operations, where precision meets power, and innovation drives production.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Enhancing Well Integrity in Hostile Environments: InWaTec Combined's Braided Line H2S Rated Wire and Tools Services In the challenging and often volatile conditions of oil and gas extraction, the durability and integrity of well intervention equipment are paramount. InWaTec Combined is at the forefront of providing robust solutions for environments where corrosive agents like CO2, H2S, and chlorides pose significant risks. Our Braided Line H2S Rated Wire and Tools Services are specifically engineered to withstand such harsh well conditions, ensuring safety, reliability, and performance. Our braided line services are not just a component of our offerings; they are a testament to our commitment to innovation and resilience. The braided wirelines we employ are fabricated with materials offering extraordinarily high stability against a spectrum of corrosive threats, including: Corrosion: Our lines are designed to resist the chemical attacks that are common in high CO2 environments, maintaining their integrity over time. Stress Corrosion: The high-stress conditions of downhole operations can lead to vulnerabilities in standard materials. Our H2S rated wires are built to endure these stresses without succumbing to corrosion. Intergranular Corrosion: This type of corrosion can compromise the grain boundaries of metals. Our wirelines are composed of alloys that maintain their structure even in the presence of corrosive elements. The presence of H2S, known for its corrosive nature and potential to create hazardous work conditions, demands a solution that not only withstands this environment but also ensures the safety of the operation. InWaTec Combined's H2S rated wires and tools are up to this task, providing a reliable means of well intervention and maintenance without the risk of degradation. Our services extend to a suite of tools compatible with these high-strength wirelines, ensuring that every aspect of the intervention process is optimized for H2S-rich environments. From logging to perforating, our tools are designed to perform flawlessly, providing accurate data and successful outcomes despite the presence of aggressive agents. Choosing InWaTec Combined's Braided Line H2S Rated Wire and Tools Services means opting for a partner with an uncompromising stance on safety and quality. We understand the challenges of operating in hostile well environments, and we are dedicated to providing solutions that meet these challenges head-on. With InWaTec Combined, operators can confidently address well intervention tasks in even the most demanding conditions, assured by our high-quality materials and cutting-edge technology. Our commitment to excellence is your pathway to maintaining well integrity and achieving uninterrupted production, even in the face of H2S and other corrosive agents. Trust InWaTec Combined to deliver resilience and reliability downhole, where it matters most.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Revitalizing Wells with Precision: InWaTec Combined’s E-line Re-perforating Services In the lifecycle of an oil or gas well, the need to enhance production or manage reservoir depletion often leads to re-perforating—a strategic intervention aimed at revitalizing well performance. InWaTec Combined's E-line Re-perforating Services leverage the proven efficacy of wireline technology to refine and optimize this crucial process. Wireline, or electric line, has been the traditional mode for deploying perforating guns due to its substantial benefits. The real-time depth control ensures that each perforation is placed with surgical precision, while the selectivity afforded by wireline allows for targeted interventions, focusing on zones with the greatest potential for increased production. Moreover, the reduced logistics of wireline operations, as opposed to tubing deployment, offer a streamlined, cost-effective approach to well servicing. Historically, wireline perforating guns were differentiated based on their use—either as casing guns for pre-completion perforation or through-tubing guns for post-completion jobs. In today's industry, however, this distinction has been transcended. InWaTec Combined has embraced the versatility of wireline to deliver any engineered perforating system, regardless of the well's stage of life, alongside an extensive array of explosive devices. Our E-line Re-perforating Services are not merely about revisiting existing perforations. They represent a strategic re-evaluation and reconfiguration of the well's production strategy. Whether it's addressing areas of the reservoir that were initially bypassed, bypassing damaged perforations, or creating new pathways in depleted zones, our re-perforating services are tailored to meet the unique demands of each well. At InWaTec Combined, we understand that re-perforating is an opportunity to enhance well productivity significantly. Our expert teams, equipped with advanced diagnostic tools, evaluate the well's current status to identify the most promising zones for re-perforation. With this data, we employ the latest in shaped-charge technology and explosive devices, ensuring that new perforations deliver the maximum flow and recovery possible. Choosing InWaTec Combined's E-line Re-perforating Services means entrusting your well's performance to a company that values precision, efficiency, and innovation. Our commitment to excellence ensures that your re-perforating interventions are executed with the highest level of expertise, from planning to execution. Partner with us to revitalize your wells. With InWaTec Combined's E-line Re-perforating Services, you can expect to turn potential into production, optimizing your well's output and extending its productive life. Let us help you unlock the hidden value in your wells, one precise perforation at a time.

Service

In Stock

Service

New

API

Land Freight

Safeguarding Well Integrity with InWaTec Combined’s Advanced E-Line Casing Inspection Services At InWaTec Combined, we understand that maintaining the structural integrity of well casings is paramount to the uninterrupted production and long-term viability of any well. That’s why we are committed to offering comprehensive E-Line Casing Inspection Services, employing an array of sophisticated diagnostic techniques to detect and prevent casing failures before they compromise well operations. Casing failures can arise from a variety of factors, including deformation, physical wear, and corrosion. These issues, if not identified and addressed promptly, can lead to diminished well production or catastrophic failures. Recognizing the critical nature of this aspect of well maintenance, InWaTec Combined utilizes four industry-standard techniques for casing inspection, each offering unique insights into the condition of the wellbore structure: Cased-Hole Calipers: Our E-Line delivered cased-hole calipers provide precise measurements of the internal dimensions of the casing, identifying areas of deformation and wear that may not be immediately apparent. Flux-Leakage Tools: These tools detect flaws in the casing by identifying areas where magnetic flux leakage occurs, indicative of potential corrosion or metal loss. Electromagnetic Phase-Shift Tools: By measuring variations in electromagnetic fields, these tools can pinpoint defects within the casing structure, offering an early warning against integrity breaches. Ultrasonic Tools: Our ultrasonic inspection tools use high-frequency sound waves to assess the thickness of casing walls, detecting thinning that could lead to potential collapse. In addition to these methods, InWaTec Combined also employs ultrasonic radial-cement-evaluation devices and modified openhole-imaging devices. These specialized tools are invaluable in evaluating the casing for signs of internal or external metal loss—a critical step in preventing unexpected downtime and ensuring the integrity of the well. Our E-Line Casing Inspection Services are about more than just diagnostics; they provide a strategic approach to well maintenance. By utilizing these advanced tools, we offer a detailed assessment of the casing's condition, enabling operators to take preemptive action to rectify issues before they escalate into more significant problems. In choosing InWaTec Combined for your casing inspection needs, you are selecting a partner dedicated to the highest standards of well integrity and operational safety. We provide a comprehensive, E-Line delivered, diagnostic service that ensures your well remains productive, safe, and profitable for years to come. Trust in the precision of our technology and the expertise of our team to maintain the backbone of your well operations—because at InWaTec Combined, we believe that prevention is the key to sustainable production.

![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

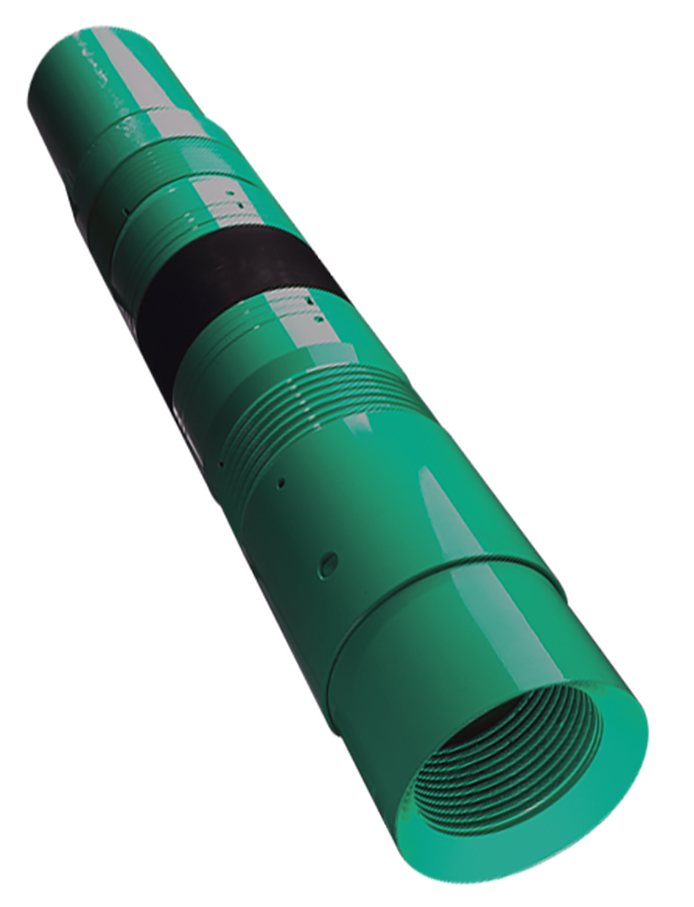

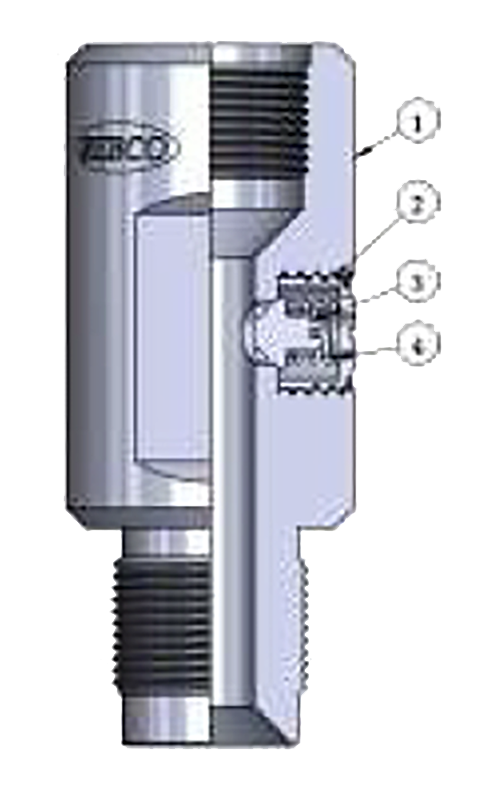

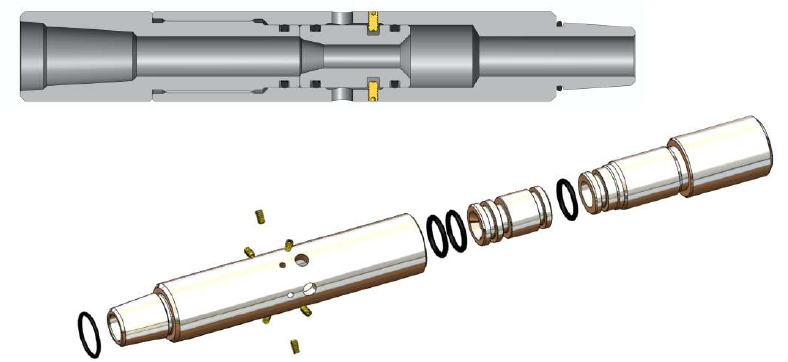

The WI retrievable injection valve is a high-performance, high-flow rate injection valve. High throughput is achieved by a unique valve configuration that minimizes turbulent and potentially erosive flow. Operation is not dependent on a specific flow rate, pressure, or setting depth, thus negating the need for adjustment over time. The valve incorporates a metal-to-metal valve and seat energized by the combination of an integral spring and well pressure acting from below. The WI injection valve can be deployed on a wireline lock or through-tubing pack-off device, providing flexibility not available with alternative injection valve systems. As a result of the simple design with fewer parts, redress and repair costs are considerably lower than those for other injection valve systems. Applications The WI injection valve is primarily used in water injection applications as an alternative to conventional tubing or wireline-set safety valves. The valve is also commonly used as a retrofit solution in water injectors in which a tubing to annulus leak has occurred. The valve can be deployed below the leak point to eliminate uncontrolled annulus pressure increases when the injection stops. Features » Compatible with all known lock systems » Dedicated designs to suit Halliburton EB0 intervention packers » Enhanced internal flow profile » Simple design and construction » Flow-loop testing performed to establish pressure drop versus pump rate *information referenced from supplier catalog.

Buy

Made to Order

Product & Service

New

API

Land Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Unlocking Efficiency: HOCA Oil Tools' Lock Mandrels for Tubing In the demanding realm of oil and gas operations, ensuring the integrity and functionality of well components is paramount. HOCA Oil Tools, a pioneer in downhole slick line tools, introduces its cutting-edge Lock Mandrels for Tubing – an essential solution designed to enhance the performance and reliability of downhole activities. These tools are engineered for precision, delivering unmatched reliability and performance to meet the rigorous demands of modern well operations. HOCA's Lock Mandrels for Tubing: Precision-Engineered for Superior Performance Our Lock Mandrels for Tubing are designed to securely latch into the tubing string, providing a stable base for various downhole tools and devices. Tailored to accommodate different tubing sizes and pressures, they are essential for the effective management and control of wellbore fluids. Fabricated from high-quality materials and built to withstand the harshest downhole environments, HOCA's Lock Mandrels ensure operational success and longevity. Experience the HOCA Oil Tools Advantage Opting for HOCA Oil Tools’ Lock Mandrels for Tubing means choosing a partner committed to your operational success. Our dedication to quality and innovation ensures that our products not only meet but exceed the expectations set by the demanding oil and gas industry. Incorporating our Lock Mandrels into your tubing operations signifies a step towards enhanced efficiency, safety, and control. With HOCA Oil Tools, you gain more than just equipment; you gain a strategic advantage supported by our expertise and unwavering commitment to excellence. Choose HOCA Oil Tools for your downhole needs and join the ranks of satisfied clients who rely on our Lock Mandrels for Tubing to secure their operational success. Partner with us, and harness the power of precision-engineered solutions to elevate your downhole activities. With HOCA Oil Tools, empower your downhole operations with tools that redefine reliability, efficiency, and performance in the oil and gas industry.

Buy

In Stock

Product & Service

New

API

Air Freight

Subsurface Safety Valve for Injection Wells 5.4 inch

WI Valve![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

The WI retrievable injection valve is a high-performance, high-flow rate injection valve. High throughput is achieved by a unique valve configuration that minimizes turbulent and potentially erosive flow. Operation is not dependent on a specific flow rate, pressure, or setting depth, thus negating the need for adjustment over time. The valve incorporates a metal-to-metal valve and seat energized by the combination of an integral spring and well pressure acting from below. The WI injection valve can be deployed on a wireline lock or through-tubing pack-off device, providing flexibility not available with alternative injection valve systems. As a result of the simple design with fewer parts, redress and repair costs are considerably lower than those for other injection valve systems. Applications The WI injection valve is primarily used in water injection applications as an alternative to conventional tubing or wireline-set safety valves. The valve is also commonly used as a retrofit solution in water injectors in which a tubing to annulus leak has occurred. The valve can be deployed below the leak point to eliminate uncontrolled annulus pressure increases when the injection stops. Features » Compatible with all known lock systems » Dedicated designs to suit Halliburton EB0 intervention packers » Enhanced internal flow profile » Simple design and construction » Flow-loop testing performed to establish pressure drop versus pump rate *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Air Freight

USB Adapter Magnetic USB Charger

Self-designed Magnetic USB Connectors![]() Provix in New Lowell

Provix in New Lowell

Simplify Your Charging with the Wisdom USB Adapter – A Smart Solution from Provix Provix is excited to unveil the Wisdom USB Adapter, a cutting-edge charging accessory designed to enhance your charging experience. This magnetic USB charger features self-designed connectors that redefine convenience and efficiency in powering your devices. Innovative Magnetic USB Connectors The USB Adapter boasts unique magnetic USB connectors, specifically engineered for a seamless and secure connection. This design allows for quick and effortless attachment to your devices, ensuring a stable and consistent charge. The user-friendly nature of these connectors makes the charging process incredibly simple, even in less-than-ideal conditions or tight spaces. Versatile for Various Environments The Wisdom USB Adapter is designed to extend your charging capabilities across multiple settings. Whether you're at home, in the office, a hotel, or on the go, this adapter provides a reliable charging solution. Its white color and sleek design add a touch of elegance to your tech collection, making it a stylish and practical choice. Durable and High-Quality Construction Crafted with a focus on durability, the USB Adapter features a high-quality magnetic connector and a robust connecting cable. With a cable length of 1 meter, it offers the flexibility and reach needed in various charging situations. Effortless Charging Process Using the Wisdom USB Adapter is straightforward and efficient: 1. Connect the magnetic head to the multi-purpose lamp's charging interface. 2. Attach the USB connector end to a WISDOM power adapter or any standard USB port. This simple two-step process ensures your devices are charged without any hassle, keeping them ready for use whenever you need them. Ideal for Modern Professionals The Wisdom USB Adapter is a perfect match for professionals who require a reliable and efficient charging solution for their equipment. Its compatibility with various devices and ease of use make it an indispensable tool for miners, construction workers, and outdoor enthusiasts. Get Your Wisdom USB Adapter Today Embrace the convenience of the Wisdom USB Adapter, available now at Provix. Visit our website at www.provix.net to discover more about this innovative charging solution and explore our range of high-quality mining and construction equipment. Stay charged and ready with Wisdom's advanced technology.

Buy

In Stock

Manufacturer

New

ANSI

Air Freight

MAGIC WELD 200 light-weight 200-Amp DC Stick welder

Engine Driven Welder![]() Canaweld Inc. in Vaughan

Canaweld Inc. in Vaughan

Introducing the MAGIC WELD 200: Unleash the Power of Welding and Portability! At Canaweld, we understand the demands of welders on-site and in the field. That's why we're thrilled to present the MAGIC WELD 200 - the ultimate fusion of welding capabilities and generator portability, designed to elevate your welding experience to new heights. Powerful Performance in a Lightweight Package The MAGIC WELD 200 is a true powerhouse in its class, offering an impressive 200-Amp DC Stick welder in a lightweight design. Built for everyday use, this versatile welder doubles as a portable generator, providing the power and efficiency you need in any welding or electrical project. Engineered for Precision and Power Paired with the exceptional Honda GX 270 four-stroke engine, the MAGIC WELD 200 delivers a powerful and steady arc for flawless welding performance. Its auto idle feature maximizes fuel efficiency and extends the engine's lifespan, ensuring you can tackle even the most demanding tasks with ease. The Perfect Companion On-Site or Around the Farm Weighing just 135 lbs. (61 Kg) and boasting a remarkable 200A in 60% duty cycle, the MAGIC WELD 200 is your go-to companion on-site or around the farm. Its sturdy construction and full steel frame offer optimal machine protection, while the optional extra trolley and wheels add even more convenience to your welding journey. Safety and Innovation at the Core Safety is our top priority, and that's why the MAGIC WELD 200 is equipped with the "Power Optimizer" function - a special feature patented by MOSA. This innovative technology prevents engine overload when nearing its power limit, keeping you and your equipment safe. Certified Excellence Rest assured, the MAGIC WELD 200 is CE certified, meeting the highest standards of quality and safety. Its engine complies with U.S. EPA and California EXH/EVP SORE Regulations, making it an eco-friendly and compliant choice. Unleash the Magic of Welding and Portability With the MAGIC WELD 200, you can now experience the perfect harmony of welding capabilities and generator portability. Empower yourself to take on any welding or electrical challenge with precision and power. Canaweld - Your Partner in Welding Excellence At Canaweld, we take immense pride in providing welding machines and accessories that cater to the unique needs of welders in the oil and gas industry. The MAGIC WELD 200 embodies our commitment to excellence and innovation, and we are thrilled to offer you this game-changing welding solution. Unlock the magic of welding prowess and unparalleled portability with the MAGIC WELD 200. Your welding success awaits! Canaweld - Empowering Your Welding Journey!

Buy

In Stock

Manufacturer

New

ASME

Land Freight

![]() Cleanstream B.V. in Ter Apel

Cleanstream B.V. in Ter Apel

Introducing Enviro-Syn® BSD-40™: The Solution to Your NORM Scale Dissolving and Descaling Needs Cleanstream is excited to present our high-performance NORM scale dissolver and descaler, Enviro-Syn® BSD-40™. Our product is specially designed to efficiently remove sulfate scale, with a unique ability to dissolve extremely high amounts of barium sulfate scales. We understand the challenges that come with BaSO4 scale formation, such as reduced production, bacterial growth, fouling of piping, tanks, and process equipment. These issues can greatly reduce the profitability of your operations. That's why we have created Enviro-Syn® BSD-40™, a product that can effectively remove these scales and help improve your operations' profitability. Our product is highly versatile and can be used in a variety of applications, including down-hole scaling issues, production well near wellbore damage from barite-based mud systems, heat exchangers/pipelines, on-shore/off-shore topside processing and production treatments, industrial boiler systems, geothermal well scale treatments, separators/hydrocyclones/degasser treatments, and injection well treatments. One of the significant advantages of Enviro-Syn® BSD-40™ is that it is not corrosive to metal or typical oilfield elastomers and seals. This means that you can use our product without the risk of damaging your equipment. At Cleanstream, we are committed to providing high-quality products that are safe for the environment and the people who use them. Our product is designed to meet the highest industry standards while providing exceptional performance. So why wait? Make the switch to Enviro-Syn® BSD-40™ today and experience the benefits of a highly effective NORM scale dissolver and descaler that is safe for your equipment and the environment. Contact us to learn more about how you can get started with Enviro-Syn® BSD-40™ and start improving your operations' profitability.

Buy

In Stock

Manufacturer

New

ISO

Land Freight

NE Safety Valve, Surface Controlled 4-1/2 inch

SCSSSV![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

The NE™ tubing-retrievable safety valve (TRSV) is a single rod-piston non-elastomer flapper valve designed for general production with enhanced reliability and long life. The valve includes the non-elastomer hydraulic actuator design from the highly reliable SP™ line of safety valves. Along with the metal-to-metal (MTM) body joints and closure mechanism, the actuator places this valve in the premium category while keeping costs economical. The simple, compact design enhances the valve’s overall reliability and provides for trouble-free operation. Applications » General production completions » Hostile well environments incompatible with elastomers Features » Non-elastomer dynamic piston seals » Simple compact design » 100% MTM well containment in closed position » Positive debris barrier at both ends of flow tube » No construction seals used in the lockout and communication system » Unique flow tube construction prevents debris from settling on top of flow tube *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Air Freight

![]() Canaweld Inc. in Vaughan

Canaweld Inc. in Vaughan

Introducing the Canaweld Welder Cart for Single Phase Machines - Your Ultimate Welding Companion! When it comes to welding, having the right equipment at your fingertips is essential. That's why we've designed the Canaweld Welder Cart - a sturdy and reliable cart that will keep your single-phase machines organized and accessible at all times. With its thoughtful features and robust construction, this cart is the perfect addition to your welding setup. Built for Strength and Durability: The Canaweld Welder Cart is crafted with a strong steel construction that ensures it can handle the demands of the oil and gas industry. Its powder coat finish adds an extra layer of protection, making it resistant to wear and tear from daily use. Rest assured, this cart is built to last. Maximum Convenience, Minimum Effort: Moving your welding equipment has never been easier. The front caster wheels on our cart swivel a full 360 degrees, allowing for smooth and effortless turning. No more struggling to maneuver your machines - our cart does the work for you. Ample Storage Space: Organize your welding essentials with ease. The Canaweld Welder Cart features three-tier shelves thoughtfully designed to accommodate all your portable MIG welders, stick welders, plasma cutters, and necessary accessories. Plus, there's enough room for consumables and a gas cylinder, ensuring you have everything you need at your fingertips. Secure Your Equipment: Your safety is our priority. That's why we've equipped the cart with a chain to secure the gas tank firmly in place. Worried about keeping your cables and helmet tidy? The side hook provides a convenient storage solution for them, eliminating clutter and potential hazards. Unbeatable Dimensions: The Canaweld Welder Cart boasts spacious shelf dimensions that perfectly cater to your welding equipment: • Top Shelf: 18 X 11 X 1 inches • Middle Shelf: 15.5 X 11 X 1 inches • Lower Tray: 27.7 X 11.5 X 2 inches • Gas Bottle Space: 10.2 X 11.4 X 2 inches Ultimate Load Capacity: Our cart can handle the weight. With a load capacity of 110 lbs. (50 kg), you can trust that your valuable equipment is safe and secure while on the move. Efficiency Meets Style: The Canaweld Welder Cart is more than just a functional tool - it's a sleek and stylish addition to your welding setup. Its design not only optimizes your workflow but also adds a touch of professionalism to your workspace. Upgrade Your Welding Experience: Say goodbye to the hassle of transporting your welding equipment and embrace the convenience of the Canaweld Welder Cart. It's time to work smarter, not harder. Elevate your welding experience today with Canaweld - your trusted partner in welding solutions.

Buy

In Stock

Manufacturer

New

ASME

Land Freight

OCTG Casing from 4 inch to 36 inch for oil and gas well completions

OCTG Casing![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

OCTG (Oil Country Tubular Goods) refers to the piping products that are used in oil and gas production and drilling activities. OCTG pipe normally is manufactured based on API specifications. Oil country tubular goods (OCTG) is a family of seamless rolled products consisting of drill pipe, casing and tubing subjected to loading conditions according to their specific application. Casing is the pipe placed in the well that is not exposed to flowing fluids from the reservoir to surface. It is cemented in place and provides strength and stability to the drilled borehole. Our international network of manufacturers and warehouses have almost all weights and grades in stock.

Buy

In Stock

Product

New

API

Sea Freight

C-1 Single Grip Invertible Packer

C-1 Baker Packer![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

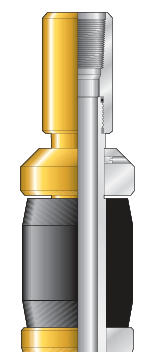

The C-1™ packer can be run as a conventionally set packer or, when run upside down, it can be set in compression. Emergency releases are provided for tension and compression operations. The G™ packer is an economical, compression-set packer, intended for lower pressure production applications. It is set by one-quarter-turn right-hand rotation. Release is accomplished by straight pickup of the tubing. If it is necessary to move the packer further downhole after release, one-fourth-turn left-hand rotation will put the tool back into the running position.

Buy

In Stock

Product

API

Sea Freight

![]() ALCiT in Mississauga

ALCiT in Mississauga

Elevate Public Sector Operations with ALCiT's Dedicated Solutions In the world of the public sector, the demands are constant – achieving more with less while navigating an ever-expanding sea of complexity. As challenges evolve, cybersecurity remains a paramount concern. ALCiT understands the intricate dynamics you face, and we're here to provide solutions that not only work but excel in the unique landscape of the public sector. Security: Your Ultimate Priority, Our Expertise Cybersecurity isn't just a checkbox; it's a commitment. In the public sector, where the stakes are high and the responsibilities are monumental, security can't be compromised. ALCiT is your dedicated partner, ensuring that every solution we provide is fortified with security measures that align with the gravity of your mission. A Portfolio Tailored to Excellence ALCiT understands that one-size-fits-all solutions won't cut it. That's why we've curated a portfolio of solutions, each adaptable to your unique needs. Our solutions, rooted in enterprise-grade tools, are pre-configured for optimal performance, delivering maximum value in record time. Whether deployed individually or as an integrated suite, we ensure your operations run seamlessly. Public Sector Solutions That Excel Security Operation Center (SOC) as a Service: Trust is earned through vigilance. Our 24/7 SOC monitoring offers round-the-clock surveillance, providing real-time threat detection and response. In just weeks, your security operations will be elevated to new heights. Network Access Control (NAC): Control isn't a luxury; it's a necessity. ALCiT's NAC empowers you to regulate network access, ensuring only authorized devices enter your domain, bolstering security and control. Network Refresh: Simplify your network management and enhance security posture with our network refresh solutions. Choose between a Service-based approach or a purchase model – either way, we ensure your network is optimized for success. Secure Today, Empower Tomorrow ALCiT's commitment to the public sector goes beyond services; it's a partnership built on trust and excellence. Let us empower your operations, enable your teams, and ensure your data remains fortified against the evolving challenges of the digital realm. Elevate public sector operations with ALCiT's dedicated solutions.

Service

Made to Order

Service

New

ISO

Digital

Partnered with Dell Technologies

Cybersecurity![]() ALCiT in Mississauga

ALCiT in Mississauga

Elevate Your Digital Transformation with ALCiT: Proud Partners with Dell Technologies In the ever-evolving landscape of technology, a strategic partnership is the key to unlocking your organization's full potential. ALCiT stands proudly as your bridge to a complete digital transformation, and we're thrilled to announce our collaboration with Dell Technologies – a powerhouse in innovation and solutions. Welcome to a future where success is redefined. The Power of Complete Solutions With the rapid acquisitions and consolidations that have shaped the industry, Dell EMC boasts one of the most comprehensive product portfolios available. A complete solution from a single vendor brings a plethora of benefits that extend beyond the ordinary: Stability That Sets You Apart: Stability isn't just a buzzword – it's the foundation of successful operations. With Dell's products, your solutions are anchored in stability, providing a robust platform for your digital transformation journey. Security Beyond Measure: In today's cyber landscape, security is paramount. Dell's solutions are fortified with security measures that align with the gravity of your mission, ensuring your data and operations remain impenetrable. Ease of Maintenance, Unprecedented Ease: Complexity need not translate to difficulty. Dell's products are designed for seamless maintenance, empowering your teams to focus on innovation rather than troubleshooting. One Call, One Solution: Issues arise, but resolution doesn't have to be complicated. Dell's ecosystem enables a single point of contact for issue resolution, ensuring quick and efficient support whenever you need it. Unveiling a PC Revolution Dell's reputation isn't just built on technology; it's built on trust. Their comprehensive line of PCs, backed by industry-leading warranty support, redefines the PC experience. No more waiting for parts or tech – Dell ensures that your PCs remain operational, boosting productivity and minimizing downtime. Empowering Your Transformation Journey Whether you're looking to rejuvenate your datacenter or embark on a Windows PC refresh program, ALCiT in partnership with Dell Technologies is here to transform your vision into reality. As your dedicated partners, we're excited to collaborate and make your digital aspirations come true. Secure Today, Transform Tomorrow ALCiT and Dell Technologies unite to redefine your digital destiny.

Service

Made to Order

Service

New

ISO

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Navigating Offshore Challenges with InWaTec Combined’s Offshore Mini-Coil Services Offshore oil and gas operations come with a unique set of logistical challenges. In the face of limited deck space and crane capacity, traditional coiled tubing units (CTUs) often fall short in providing the necessary services without compromising operational economics. InWaTec Combined rises to the occasion with our Offshore Mini-Coil Services, designed to deliver efficient, cost-effective well intervention and maintenance solutions in even the most constrained offshore environments. Compact Efficiency: Our capillary/mini-coil CTU is a game-changer for offshore operations. Its compact design minimizes the footprint on the deck, providing a practical alternative to bulkier traditional units. This space-efficient solution is crucial on platforms where every square foot counts. Lift and Load Advantages: The lightweight nature of our Mini-Coil CTU addresses the common challenges of crane limitations. With the reduced load requirements, our Mini-Coil equipment can be easily maneuvered and set up, facilitating a range of well services without the need for heavy lifting equipment. Versatile Applications: Despite its compact size, the Mini-Coil CTU is robust in capabilities. It's adept at a multitude of tasks, from precision interventions like chemical treatments and scale removal to essential maintenance procedures and even wellbore cleanouts. Economic Solution: InWaTec Combined’s Offshore Mini-Coil Services are not just operationally advantageous; they also present significant cost savings. The reduced logistical demands coupled with the efficiency of our Mini-Coil operations translate into a more economical approach to servicing wells offshore. Customized Service Delivery: Understanding that no two wells or offshore platforms are the same, we offer customized Mini-Coil solutions tailored to the specific requirements of each operation. Our team of experts meticulously plans every aspect of the service delivery, ensuring that it aligns perfectly with our clients' operational and economic objectives. At InWaTec Combined, we are committed to innovation and excellence in offshore well services. Our Offshore Mini-Coil Services embody this commitment, providing operators with the assurance that even under the constraints of limited deck space and crane capacity, their wells can be serviced efficiently and effectively. Choose InWaTec Combined for your offshore well interventions, and experience the strategic advantage of our Offshore Mini-Coil Services. We are dedicated to optimizing your operations, ensuring that your offshore wells maintain peak performance with minimal disruption. Let us bring our compact, powerful solutions to your platform, where space is at a premium, but potential is limitless.

Service

In Stock

Service

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

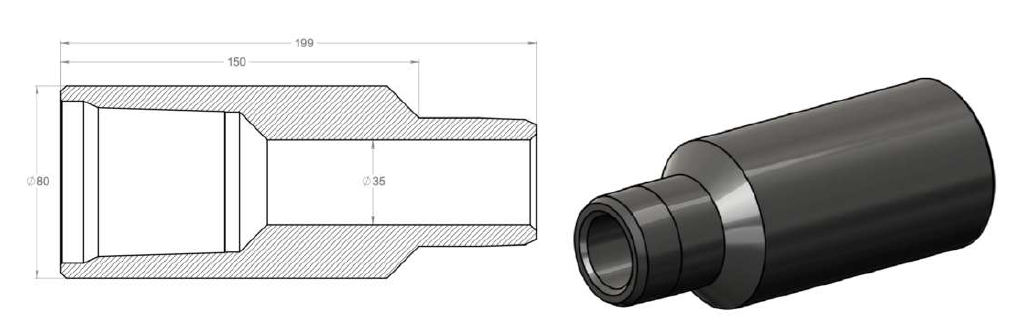

Introducing the XOV Crossover Tool from Marlin Oil Tools: Your Solution for Seamless Downhole Connections Marlin Oil Tools is proud to offer the XOV Crossover Tool, a versatile downhole tool designed to facilitate the connection of two tools or pipes with differing threads, ensuring seamless integration within your Bottom Hole Assembly (BHA) during oil and gas operations. Engineered for adaptability, the XOV Crossover Tool is available in a wide range of designs, types, and sizes of threads to meet the diverse needs of the industry. Key Features of the XOV Crossover Tool: Versatile Thread Compatibility: Designed to connect components with different thread patterns, enhancing operational flexibility and efficiency. Customizable Design Options: Available in various designs and specifications, including multiple outer diameters and inner bore sizes, to perfectly match your operational requirements. Precision Engineering: Features precise thread codes for both internal (Box) and external (Pin) threads, ensuring reliable and secure connections. Rapid Customization Capability: Offers quick turnaround on customized tool designs upon client request, minimizing downtime and accelerating project timelines. Durable Construction: Built to withstand the harsh conditions of downhole environments, ensuring reliability and longevity of your tool assembly. Easy Integration: Seamlessly integrates into existing BHA configurations, providing a straightforward solution to connectivity challenges in the field. Maximize your downhole operational efficiency with the XOV Crossover Tool from Marlin Oil Tools, a leading solution for connecting downhole tools and pipes with varying thread types in the oil and gas industry. This highly adaptable crossover tool is engineered to offer precision, durability, and versatility, featuring customizable options for thread sizes, diameters, and designs to meet the specific needs of your operations. With its capability for rapid customization and reliable performance, the XOV Crossover Tool is the ideal choice for ensuring seamless connections and enhancing the integrity of your downhole tool assemblies. Choose Marlin Oil Tools for your crossover needs and experience the difference in quality and service. Why Choose the XOV Crossover Tool from Marlin Oil Tools? Operational Versatility: Ensures compatibility across a broad spectrum of downhole tools and pipe threads. Customization to Fit: Tailors to your specific operational needs with customizable designs and precise threading. Quick Response Time: Provides fast turnaround on custom requests, keeping your projects on schedule. Enhanced Connectivity: Guarantees secure and reliable connections, reducing the risk of operational issues. The XOV Crossover Tool by Marlin Oil Tools represents the cutting edge in downhole connectivity solutions, offering unparalleled adaptability, precision, and reliability for your oil and gas operations. Incorporate the XOV Crossover Tool into your tool assembly to achieve optimal performance and operational success.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Poseidon Robotics in Chandler

Poseidon Robotics in Chandler