Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

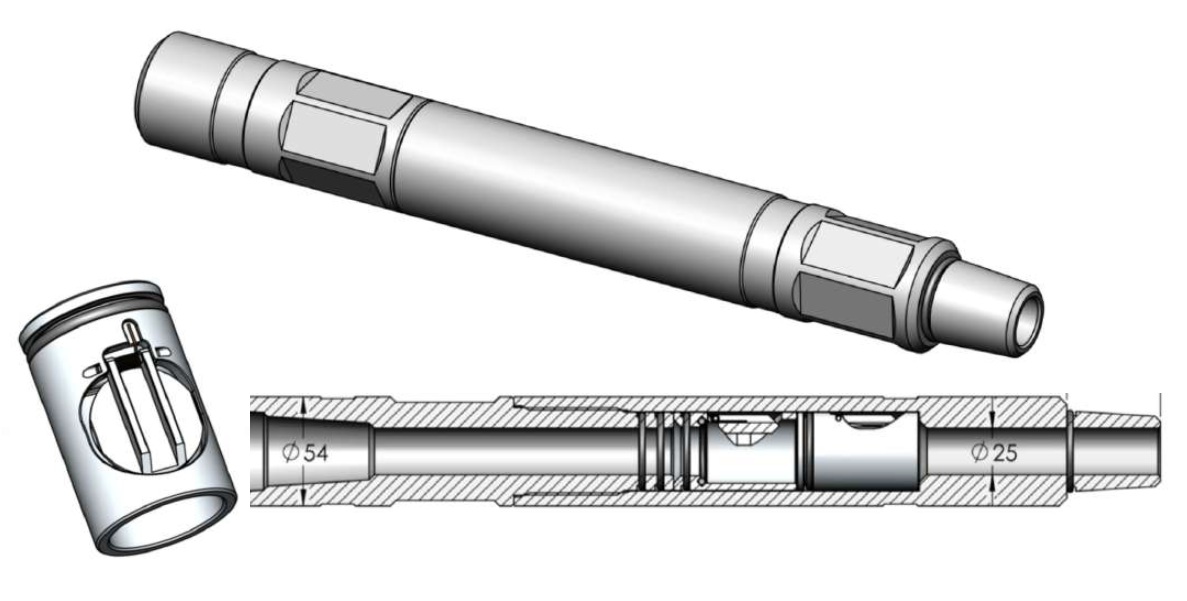

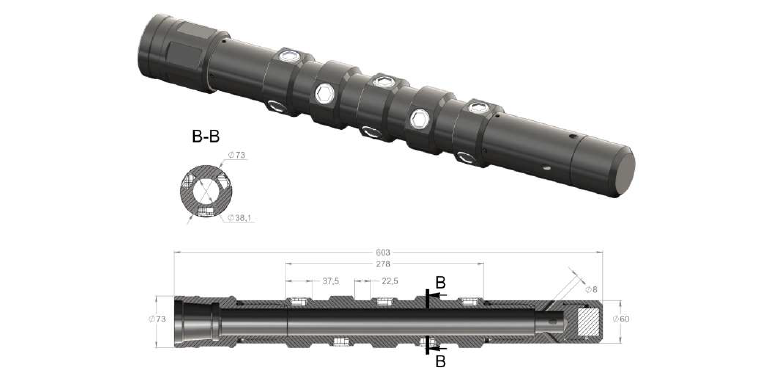

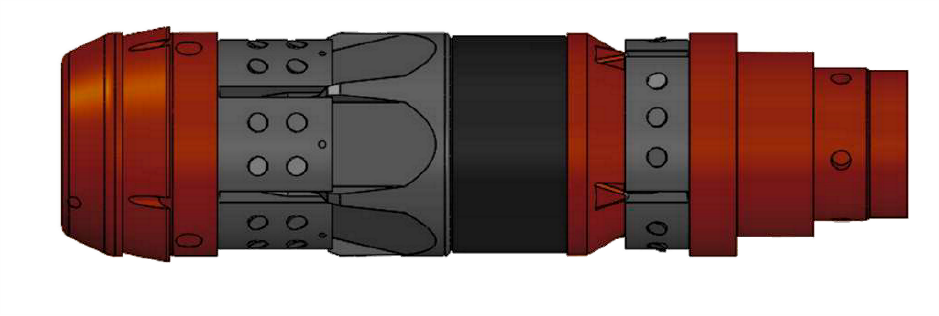

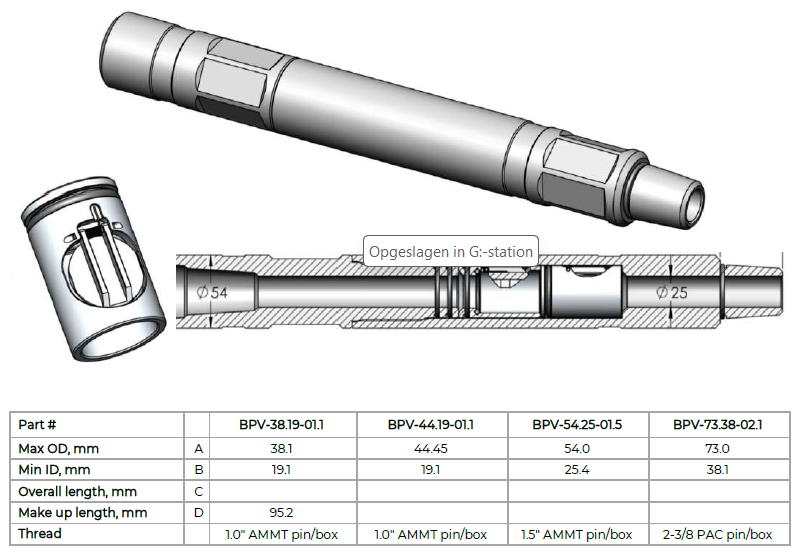

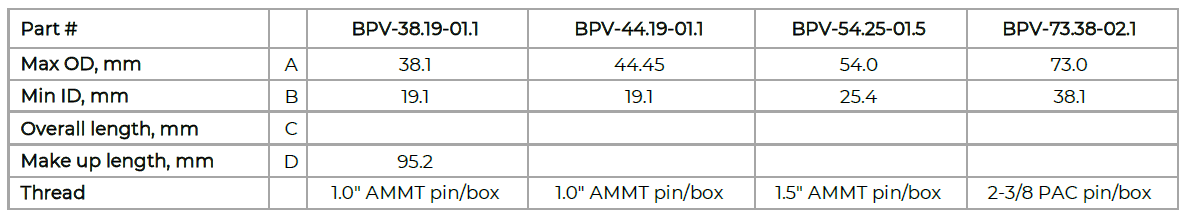

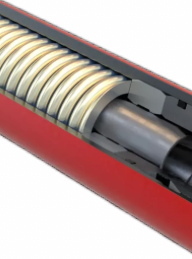

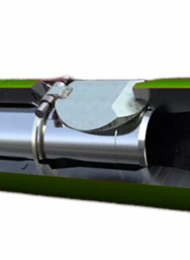

BPV Coiled Tubing Tool

Also known as:

Coiled Tubing Downhole Tool, Dual Flapper Check Valve, DFCVBuy

Made to Order

Manufacturer

New

API

Land Freight

Title:

Back Pressure Valve for Coiled TubingModel Number:

BPV-38.19-01.1Availability:

Made to OrderDelivery Time (weeks):

2 - 4 WeeksIn Stock

Transaction Type

BuyCondition

NewWeight

Based on Specs lbsLocation

CanadaCompany Type

ManufacturerQuality Assurance

APIPrice

Request for QuoteMaterial

SteelBrand Name

Marlin Oil ToolsShipping

Land FreightNotes

Double flapper back pressure valve this is a downhole tool, which installed in the bore hole assembly (BHA) during well intervention and let the fluid flow only in one direction – downwards.

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the SBA Straight Bar from Marlin Oil Tools: The Essential Downhole Tool for Enhanced Well Intervention Precision Marlin Oil Tools proudly presents the SBA Straight Bar, a specially designed downhole tool that revolutionizes well intervention operations. As an integral part of the Bottom Hole Assembly (BHA), the SBA Straight Bar addresses the critical challenge of coil tubing deformation, ensuring a straighter and more effective pathway for well intervention tools. Key Features of the SBA Straight Bar: Enhanced BHA Stability: The SBA Straight Bar provides the necessary rigidity and straightness to the BHA, minimizing the risk of deformation and ensuring smoother operations. Improved Wellbore Navigation: By maintaining a straighter path, the SBA Straight Bar significantly reduces the chances of the BHA resting against the well walls or encountering obstacles during transitions. Optimal Centering: Its rigid and straight design aids in better centering of the BHA within the wellbore, crucial for the precision of well intervention tasks. Seamless Passage: The SBA Straight Bar facilitates seamless passage through wellbore expansions and recessions, including critical points like blowout preventers, enhancing operational safety and efficiency. Versatile Integration: Designed for easy integration into any BHA configuration, the SBA Straight Bar is suitable for a wide range of well intervention activities, offering unparalleled adaptability. Elevate your well intervention strategies with the SBA Straight Bar from Marlin Oil Tools, a leading-edge solution designed to combat coil tubing deformation and ensure precise downhole operations in the oil and gas industry. The SBA Straight Bar enhances BHA stability, improves wellbore navigation, and ensures optimal centering and seamless passage through wellbore transitions. This tool is an indispensable addition to your BHA, providing the rigidity and straightness necessary for effective well intervention. Choose the SBA Straight Bar for a reliable, efficient, and versatile solution to well intervention challenges. Why Choose the SBA Straight Bar from Marlin Oil Tools? Superior Operational Precision: Ensures straighter coil tubing pathways for enhanced precision in well intervention tasks. Increased Operational Safety: Minimizes the risk of BHA hang-ups and obstructions, ensuring safer operations. Adaptability to Well Conditions: Capable of navigating through complex well architectures, including areas of expansion and recession. Streamlined Well Intervention: Promotes smoother, faster, and more efficient well intervention procedures. The SBA Straight Bar by Marlin Oil Tools represents the forefront of downhole tool technology, providing operators with the means to enhance well intervention accuracy and operational success. Incorporate the SBA Straight Bar into your well intervention toolkit to achieve superior performance and outcomes.

Buy

Made to Order

Manufacturer

New

API

Land Freight

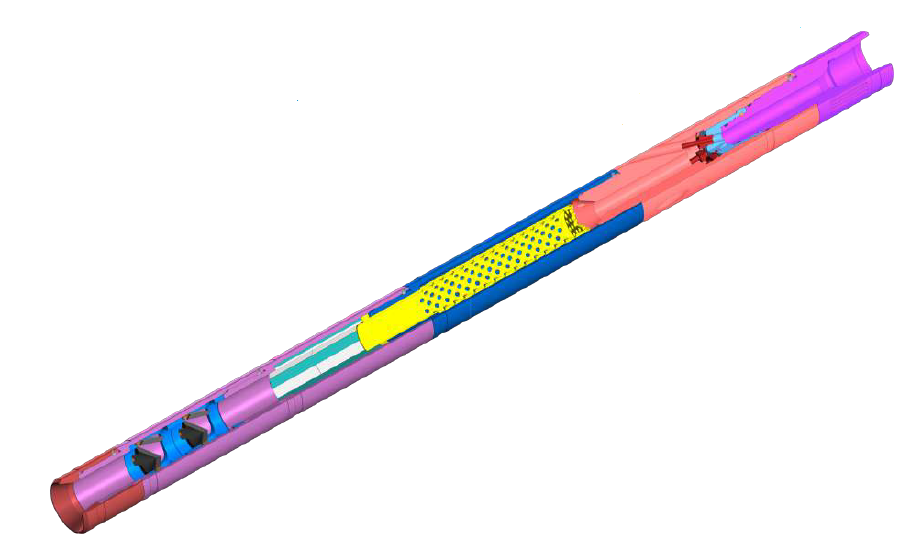

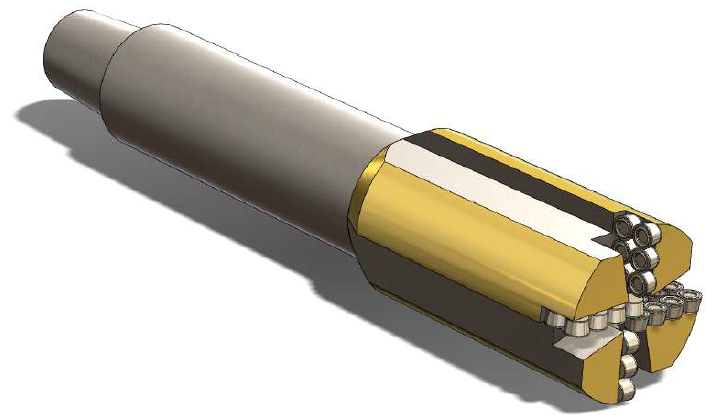

Positive Displacement Motor for Coiled Tubing Applications

PDM Positive Displacement Motor![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the PDM (Positive Displacement Motor) from Marlin Oil Tools: The Ultimate Downhole Tool for Enhanced Coil Tubing Operations Marlin Oil Tools is proud to unveil the PDM (Positive Displacement Motor), a revolutionary downhole tool designed to maximize efficiency in coil tubing operations across the oil and gas industry. Engineered to convert the flow energy of pumping fluid into rotational force, the PDM is essential for a range of operations, from milling and cleanouts to supporting mechanical tubing cutters and Venturi junk baskets. Key Features of the PDM (Positive Displacement Motor): Energy Conversion: The PDM's main function is to transform pumping fluid energy into the rotation of the bearing mandrel, optimizing the performance of downhole tasks. Versatile Applications: Ideal for milling, cleanout operations, and as a driving force for mechanical tubing cutters and Venturi junk baskets, enhancing operational flexibility. Dual-Section Design: Comprises a robust bearing section and a power section, each designed to withstand the demands of downhole environments. Innovative Power Section: Features a stator with an inner spiral surface and a rotor with an outer spiral surface, ensuring efficient energy conversion and consistent torque. Continuous Tool Rotation: Guarantees that any tool installed below the motor receives continuous rotation, improving operational efficiency and effectiveness. Optimized for Coil Tubing: Specifically tailored for integration into the BHA during coil tubing operations, ensuring seamless performance and reliability. Elevate your coil tubing operations with the PDM (Positive Displacement Motor) from Marlin Oil Tools, a cutting-edge solution designed to transform fluid energy into mechanical rotation, optimizing downhole tasks. Whether it's milling, cleanouts, or supporting other downhole tools, the PDM enhances operational flexibility and efficiency. With its innovative power section and robust bearing assembly, the PDM ensures consistent tool rotation and performance, making it an indispensable tool for the oil and gas industry. Choose the PDM from Marlin Oil Tools for unparalleled efficiency and reliability in your downhole operations. Why Choose the PDM from Marlin Oil Tools? Enhanced Milling and Cleanout Efficiency: Specifically engineered to boost performance in critical downhole tasks. Broad Operational Flexibility: Compatible with a variety of tools and tasks, ensuring adaptability to your operational needs. Reliable Performance: Designed with durable components that guarantee consistent operation and longevity. Seamless Integration: Easily integrates into your existing BHA setup, providing a smooth operation during coil tubing interventions. The PDM (Positive Displacement Motor) by Marlin Oil Tools represents the forefront of downhole tool technology, offering oil and gas operators a powerful tool for improving efficiency and outcomes in well interventions. Incorporate the PDM into your operations to achieve superior results and operational excellence.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the MGN Flat Bottom Downhole Magnet from Marlin Oil Tools: The Premier Solution for Well Cleaning and Debris Removal in the Oil and Gas Industry Marlin Oil Tools is proud to unveil the MGN Flat Bottom Downhole Magnet, a specialized downhole tool engineered to address the critical need for thorough well cleaning in oil and gas operations. Designed to efficiently remove small metal debris, such as chips and scale, the MGN Flat Bottom Downhole Magnet is essential for maintaining the integrity and operational efficiency of wells. With its unique flat bottom design and internal passage for simultaneous flushing, this tool is a game-changer for well work preparation. Key Features of the MGN Flat Bottom Downhole Magnet: Optimized Debris Removal: The flat bottom design enhances the magnet's ability to capture and remove metal debris from the well, ensuring a cleaner wellbore environment. Simultaneous Well Flushing: Features an internal passage hole, allowing for well flushing during magnet operation, thereby maximizing cleaning efficiency and reducing downtime. Versatile Design: Capable of accommodating various well conditions with a magnetic surface that can be located along the tool body or from the end, offering flexibility in application. Customizable Connections: Marlin Oil Tools provides customizable connecting threads to ensure seamless integration with your existing downhole tool configurations. Prevention of Complications: By removing foreign metal objects and debris, the MGN Flat Bottom Downhole Magnet minimizes the potential for operational complications and accidents. Essential for Well Maintenance: Acts as a crucial step in well work preparation, helping to clear the way for further well intervention and maintenance activities. Elevate your well intervention and maintenance strategies with the MGN Flat Bottom Downhole Magnet from Marlin Oil Tools, a leading-edge solution for effective well cleaning in the oil and gas sector. This downhole magnet is specifically designed to remove metal debris, ensuring well integrity and operational efficiency. With its unique flat bottom design and internal flushing capability, the MGN Flat Bottom Downhole Magnet stands out as an essential tool for any well work preparation, offering customizable connections for a perfect fit with your operations. Choose Marlin Oil Tools for reliable, efficient, and versatile well cleaning solutions. Why Choose the MGN Flat Bottom Downhole Magnet from Marlin Oil Tools? Superior Cleaning Efficiency: Designed to effectively capture and remove a wide range of metal debris from wells. Operational Versatility: Adapts to various well conditions and integrates seamlessly with your BHA for comprehensive cleaning. Enhanced Safety Measures: By clearing metal debris, it significantly reduces the risk of downhole complications and accidents. Customization Options: Offers tailor-made connecting threads to fit your specific operational requirements and tool setups. The MGN Flat Bottom Downhole Magnet by Marlin Oil Tools represents the forefront of downhole cleaning technology, providing operators with a robust tool for enhancing well performance and safety. Incorporate the MGN Flat Bottom Downhole Magnet into your well maintenance protocols to achieve cleaner, safer, and more efficient well operations.

Buy

Made to Order

Manufacturer

New

API

Land Freight

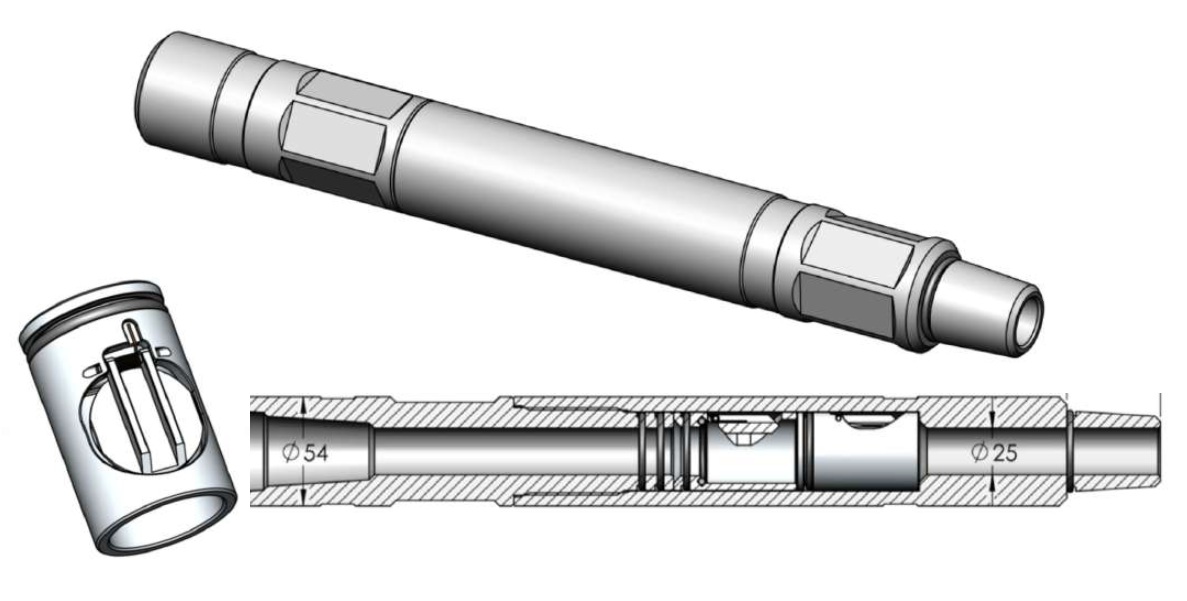

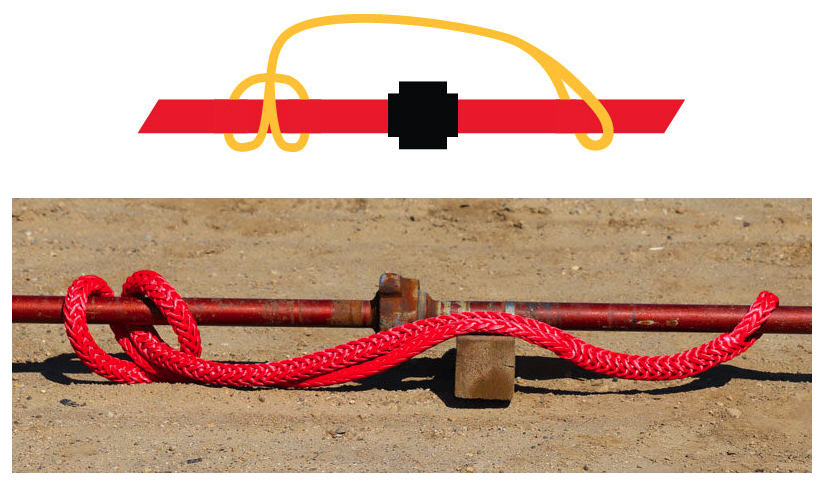

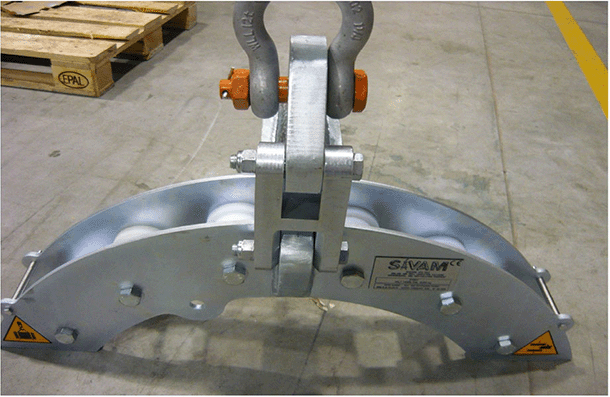

Double Roll-on Connector for Coiled Tubing

DRC Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

DRC Coiled Tubing Connector | Double Roll-On Link | Marlin Oil Tools Description: Introducing the DRC (Double Roll-on Connector) from Marlin Oil Tools, the essential connecting link between two ends of splicing Coil Tubing (CT) in the oil and gas industry. Engineered for seamless integration and reliable performance, the DRC Connector features three grooves on each end, facilitating secure fixing (rolling) of the CT and ensuring optimal stability during operations. Key Features: Double Roll-On Design: The DRC Connector boasts a double roll-on design, with three grooves on each end for enhanced stability and secure attachment of splicing Coil Tubing. This innovative design minimizes the risk of movement or displacement, ensuring uninterrupted operations in challenging wellbore environments. Robust Sealing: Equipped with O-rings positioned between the grooves, the DRC Connector provides a reliable barrier against in-line working pressures. These O-rings effectively seal the connection, preventing leaks and enhancing operational safety and efficiency during Coil Tubing applications. Streamlined Installation: With its roll-on design and precision engineering, the DRC Connector simplifies the installation process, minimizing downtime and optimizing operational efficiency. The grooves allow for easy and secure attachment of splicing Coil Tubing, facilitating swift deployment in well intervention projects. Versatile Compatibility: Designed to accommodate a wide range of splicing Coil Tubing applications, the DRC Connector offers versatile compatibility with various sizes and configurations. Its robust construction and reliable sealing capabilities make it suitable for diverse operational requirements in the oil and gas industry. Engineered Reliability: Built to withstand the rigors of oil and gas operations, the DRC Coiled Tubing Connector delivers unmatched reliability and performance. Its durable construction, combined with advanced sealing technology, ensures consistent and dependable operation, minimizing downtime and maximizing productivity. Experience enhanced efficiency and reliability in Coil Tubing applications with the DRC Connector from Marlin Oil Tools. Trust in our expertise and commitment to quality engineering for your well intervention needs.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the CEM Cement Mill from Marlin Oil Tools: The Premier Solution for Efficient Wellbore Milling Operations Marlin Oil Tools proudly presents the CEM Cement Mill, a state-of-the-art milling tool designed to optimize cement mill-out operations and tackle various downhole obstacles in oil and gas wells. Engineered for versatility and efficiency, the CEM Cement Mill is capable of grinding and washing out any object within the well that is softer than the mill's cutters, ranging from intentionally placed equipment like bridge plugs to inadvertently lost tools. Key Features of the CEM Cement Mill: Optimized for Cement Removal: Specifically designed to excel in cement mill-out operations, ensuring a clean and clear wellbore for subsequent interventions. Broad Milling Applications: Capable of milling a wide array of downhole obstacles, providing flexibility across well intervention tasks. Effective Debris Management: Equipped with multiple flushing holes, the CEM Cement Mill facilitates the circulation of drilling fluid, which efficiently removes milled particles and cools the cutting edge. Superior Cutting Technology: Features durable carbide inserts welded inside the mill body, offering exceptional grinding performance and longevity. Cooling and Lubrication: The circulation of drilling fluid not only removes debris but also prevents overheating, extending the life of the carbide inserts. Redress Services: Marlin Oil Tools offers comprehensive redress services for worn carbide inserts, ensuring your CEM Cement Mill remains at peak performance. Elevate your well intervention and milling operations with the CEM Cement Mill from Marlin Oil Tools, a leading-edge solution designed for unparalleled efficiency in cement mill-out and obstacle removal in the oil and gas industry. With its advanced design, the CEM Cement Mill tackles downhole challenges with ease, ensuring operational success. Whether you're dealing with cement, bridge plugs, or lost equipment, the CEM Cement Mill's carbide inserts and flushing holes ensure effective milling and debris removal, enhancing wellbore integrity and facilitating subsequent operations. Opt for Marlin Oil Tools' CEM Cement Mill for your milling needs and experience the difference in precision, efficiency, and durability. Why Choose the CEM Cement Mill from Marlin Oil Tools? Versatile Milling Solution: Offers a versatile tool for a wide range of downhole milling challenges. Enhanced Operational Efficiency: Designed to maximize milling efficiency and minimize downtime. Durable and Reliable: Built with high-quality materials and carbide inserts for prolonged service life. Comprehensive Support: Backed by Marlin Oil Tools' expert redress services, ensuring your tool is always in optimal condition. The CEM Cement Mill by Marlin Oil Tools represents the forefront of downhole milling technology, providing oil and gas operators with a reliable, efficient, and versatile tool for enhancing well intervention outcomes. Incorporate the CEM Cement Mill into your operations for smoother, more effective wellbore preparation and obstacle management.

Buy

Made to Order

Manufacturer

New

API

Land Freight

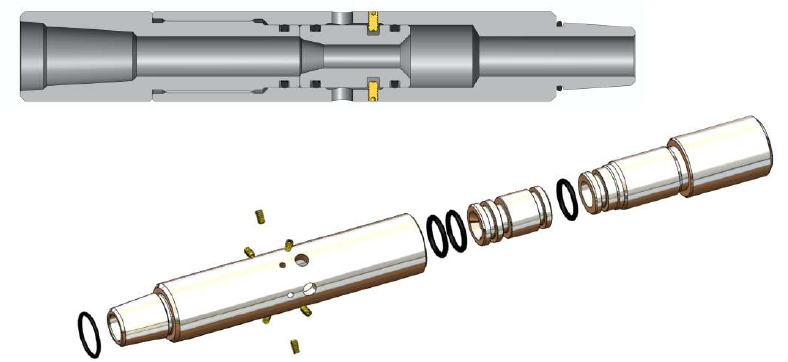

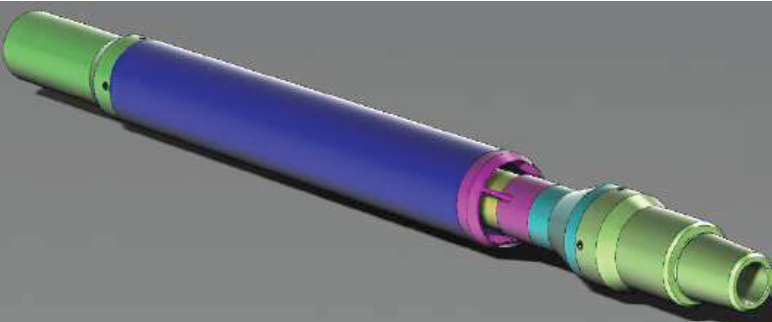

Dual Circulation Sub for Coiled Tubing

DCS Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the DCS (Dual Circulation Sub) from Marlin Oil Tools: A Pioneering Solution for Enhanced Coiled Tubing Operations in the Oil and Gas Industry Marlin Oil Tools is proud to present the DCS (Dual Circulation Sub), a state-of-the-art downhole tool designed to revolutionize coiled tubing operations. Engineered for seamless integration into the borehole assembly (BHA), the DCS is typically installed just below the hydraulic disconnect, offering unparalleled flexibility and efficiency in managing downhole circulation. Here’s a comprehensive look at the DCS’s functionality, benefits, and why it's an indispensable tool for your operations. Key Features of the DCS (Dual Circulation Sub): Activation by Steel Ball: The DCS is activated by dropping a specific size steel ball inside the coiled tubing from the surface, which travels down to seat in the shifting piston, initiating the tool's function. Pressure-Activated Circulation: Once the ball seats, it blocks downward flow, causing pressure to build above the ball. Reaching a predetermined shear level cuts the shear screws, allowing the piston to move down and open the circulation holes. Burst Disc Feature for Lost Circulation: In scenarios where circulation through the coiled tubing is lost, and the activation ball cannot be pumped down, the DCS includes a burst disc. This disc bursts under specific pressure, opening a small circulation hole to the annulus and allowing for the activation ball to be circulated down. Enhanced Operational Flexibility: The DCS offers dual circulation paths, enabling operators to manage downhole conditions more effectively and maintain continuity in operations, even in challenging circumstances. Elevate your coiled tubing operations with the DCS (Dual Circulation Sub) from Marlin Oil Tools, a leading-edge downhole tool designed for optimal fluid management and operational efficiency in the oil and gas sector. Featuring an innovative activation mechanism via a steel ball and a pressure-activated system for opening circulation holes, the DCS ensures reliable control over downhole fluid dynamics. With the added burst disc feature for overcoming lost circulation challenges, the DCS enhances operational flexibility and safety, making it a vital component of any BHA during coiled tubing interventions. Choose the DCS for a robust solution to maintaining effective circulation and operational integrity under varying downhole conditions. Why Choose the DCS from Marlin Oil Tools? Innovative Activation Mechanism: Simplifies operations with a steel ball drop method for tool activation. Dual Circulation Capability: Offers versatile circulation options to adapt to changing downhole conditions. Safety and Efficiency in Lost Circulation: The burst disc feature provides a fail-safe option for maintaining circulation. Operational Continuity: Ensures uninterrupted operations, even in challenging downhole environments. The DCS (Dual Circulation Sub) by Marlin Oil Tools represents the cutting edge in coiled tubing technology, providing operators with the tools necessary to achieve safer, more efficient, and flexible downhole operations. Incorporate the DCS into your coiled tubing operations to experience improved operational outcomes and enhanced control over well intervention processes.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the MGN Radial Downhole Magnet from Marlin Oil Tools: Your Premier Solution for Well Cleaning and Metal Debris Removal Marlin Oil Tools is proud to unveil the MGN Radial Downhole Magnet, a highly efficient downhole tool designed specifically for the oil and gas industry to address the critical need for well cleaning and maintenance. Engineered to remove small metal debris, such as chips and scale, the MGN Radial Downhole Magnet is essential for maintaining well integrity and preventing operational complications. Key Features of the MGN Radial Downhole Magnet: Efficient Debris Removal: Utilizes a powerful radial magnetic field to capture and remove small metal debris accumulated during the operation of metal tools and milling operations. Prevention of Operational Complications: By extracting small metal parts and foreign objects, the MGN Radial Downhole Magnet minimizes the risk of well complications or accidents, ensuring smoother operations. Versatile Design: Features various designs with magnetic surfaces located along the tool body or from the end, tailored to maximize debris capture efficiency. Simultaneous Well Flushing Capability: Equipped with an internal passage hole, it allows for well flushing simultaneously with magnet operation, enhancing cleaning efficiency. Customizable Connections: Offers the flexibility to manufacture any connecting threads as per customer requirements, ensuring compatibility with existing downhole tool configurations. Crucial for Well Preparation: Acts as a vital step in well work preparation, ensuring a clean operational environment free from hazardous metal debris. Elevate your well maintenance regime with the MGN Radial Downhole Magnet from Marlin Oil Tools, a leading-edge solution crafted for the effective removal of metal debris in oil and gas wells. This downhole magnet, engineered for precision and efficiency, safeguards your well operations against potential complications caused by foreign metal objects and accumulated debris. With its versatile design and simultaneous well flushing capability, the MGN Radial Downhole Magnet is indispensable for any well intervention or maintenance activity. Opt for Marlin Oil Tools’ customizable and reliable downhole magnet to ensure your well remains clean, safe, and productive. Why Choose the MGN Radial Downhole Magnet from Marlin Oil Tools? Targeted Debris Removal: Optimized for capturing a wide range of metal debris, ensuring a clean wellbore. Operational Safety: Significantly reduces the risk of well operation complications and accidents. Enhanced Cleaning Efficiency: Simultaneous flushing feature streamlines well cleaning processes. Flexible and Compatible: Customizable thread options offer seamless integration into your BHA. Essential for Well Maintenance: A critical tool for preparing wells for intervention and maximizing operational longevity. The MGN Radial Downhole Magnet by Marlin Oil Tools represents the pinnacle of downhole cleaning technology, providing operators with a robust tool for ensuring well integrity and operational efficiency. Incorporate the MGN Radial Downhole Magnet into your well maintenance toolkit for a cleaner, safer, and more productive well operation.

Buy

Made to Order

Manufacturer

New

API

Land Freight

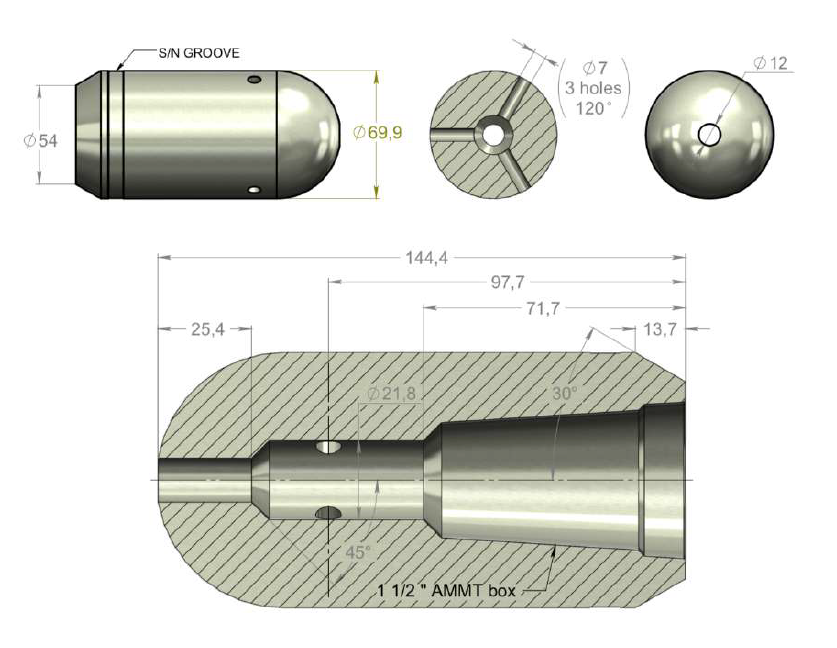

Venturi Junk Basket for Coiled Tubing Applications

VJB Venturi Junk Basket![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the VJB Venturi Junk Basket from Marlin Oil Tools: The Advanced Solution for Efficient Well Cleanout Operations Marlin Oil Tools is proud to unveil the VJB Venturi Junk Basket, a cutting-edge downhole tool engineered to tackle the challenge of removing solid debris from wells, especially when particles are too heavy for standard circulation removal. This innovative tool is designed to enhance well intervention procedures, ensuring a clean and unobstructed wellbore essential for optimal production and operational safety. Key Features of the VJB Venturi Junk Basket: Venturi Effect Cleaning: Utilizes the Venturi effect, generated by flow through the tool's nozzles, to efficiently suck solid debris and well fluid into the basket for removal. Selective Debris Filtration: Features a filter that captures large particles (>3 mm in diameter) while allowing liquid to return to the annulus, ensuring effective debris removal without losing valuable well fluids. Secure Debris Retention: Equipped with cartridges and flapper valves inside the basket to securely hold debris, even when circulation is halted, preventing backflow. Magnetic Debris Capture: Offers the option to install a magnet within the tool, enhancing the capture of small metal particles and ensuring a thorough cleanout. Expandable Collection Volume: Can be fitted with an extended housing to increase the internal volume for debris collection, accommodating larger cleanout operations. Integrated Milling Capability: When faced with compressed debris, the VJB can be mounted on a downhole motor with a crown mill shoe, allowing for the milling of compressed debris while simultaneously sucking up drilled particles. Elevate your well cleanout operations with the VJB Venturi Junk Basket from Marlin Oil Tools, a premier downhole tool designed for the efficient removal of solid debris in oil and gas wells. By harnessing the Venturi effect, the VJB enhances debris removal capabilities, particularly for heavy particles that are difficult to extract via standard circulation. With its innovative features, including selective filtration, secure debris retention, and optional magnetic capture, the VJB Venturi Junk Basket is an essential tool for maintaining well integrity and optimizing production. Whether dealing with loose or compressed debris, the VJB offers customizable solutions, including expandable collection volumes and integrated milling functionality, making it a versatile choice for comprehensive well cleanout needs. Why Choose the VJB Venturi Junk Basket from Marlin Oil Tools? Enhanced Cleanout Efficiency: Leverages the Venturi effect for superior debris removal performance. Versatile Debris Management: Captures a wide range of particle sizes, from large solids to small metal fragments. Customizable Tool Options: Adaptable design with optional extensions and magnetic capabilities to suit specific operational needs. Operational Versatility: Suitable for both loose and compressed debris, ensuring thorough well cleanout under various conditions. The VJB Venturi Junk Basket by Marlin Oil Tools represents the forefront of well cleanout technology, offering unparalleled efficiency and adaptability in debris removal operations. Incorporate the VJB into your well maintenance and intervention strategies for cleaner, safer, and more productive wells.

Buy

Made to Order

Manufacturer

New

API

Land Freight

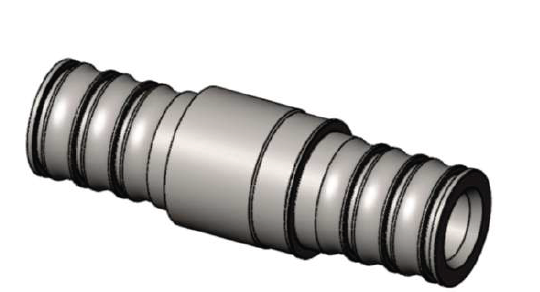

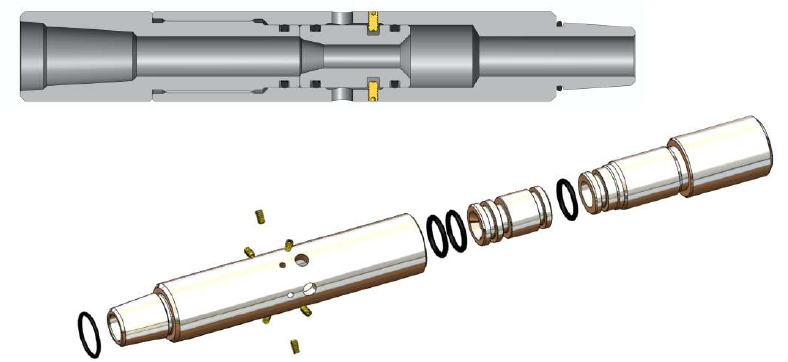

Internal Roll-on Connector for Coiled Tubing

IRC Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the Revolutionary IRC (Internal Roll-on Connector) by Marlin Oil Tools: Your Key to Efficient and Reliable Coiled Tubing Connections in the Oil and Gas Industry Marlin Oil Tools proudly presents the IRC (Internal Roll-on Connector), a cutting-edge solution engineered to enhance the efficiency and reliability of well intervention operations. Designed to seamlessly connect the smooth lower end of coiled tubing (CT) to any downhole tool, the IRC stands out for its innovative design and superior performance in the demanding environments of the oil and gas industry. Here's why the IRC is an essential tool for your well intervention operations. Key Features of the IRC (Internal Roll-on Connector): Innovative Groove Design: The IRC features unique grooves in its upper part, which are specifically designed for the secure fixing of coiled tubing through a rolling process. This design ensures a tight and reliable connection, crucial for the successful execution of well intervention tasks. Threaded Lower Part for Versatile Tool Attachment: Equipped with a threaded lower section, the IRC allows for easy and secure attachment of various downhole tools. This feature provides the versatility needed to adapt to different operational requirements, making the IRC a versatile tool in your well intervention toolkit. Enhanced Sealing with FKM 90 O-rings: To ensure the integrity of well operations, the IRC is fitted with two O-rings made from the high-quality FKM 90 material. This offers superior sealing capabilities, effectively isolating the connector's internal space from the annulus and preventing fluid leakage. Efficient Installation Process: The installation of the IRC is simplified and efficient, utilizing a mechanical tubing cutter with rolling wheels. This process not only ensures a secure connection but also minimizes downtime, allowing for quicker setup and transition between operations. Elevate your well intervention operations with the IRC (Internal Roll-on Connector) from Marlin Oil Tools, a leading innovator in coiled tubing technology for the oil and gas sector. Designed for the secure connection of coiled tubing to downhole tools, the IRC features a unique groove design for rolling fixation and a threaded lower part for versatile tool attachment. Equipped with dual O-rings made from durable FKM 90 material, it provides exceptional sealing, enhancing operational integrity. The IRC is engineered for easy installation, offering efficiency and reliability in well intervention tasks. Choose the IRC for a seamless, leak-proof connection in your coiled tubing operations. Why Choose the IRC from Marlin Oil Tools? Secure and Reliable Connection: The unique groove design ensures a robust connection between coiled tubing and downhole tools, critical for the success of well intervention operations. Operational Versatility: The threaded lower part enhances the IRC's compatibility with a wide range of downhole tools, offering operational flexibility. Superior Sealing Performance: Dual O-rings made from FKM 90 material provide outstanding sealing, protecting against fluid leakage and ensuring the safety of well operations. Streamlined Installation: Designed for efficiency, the IRC's installation process reduces operational downtime, enhancing productivity and operational flow. Marlin Oil Tools is dedicated to providing the oil and gas industry with innovative solutions like the IRC (Internal Roll-on Connector), designed to meet the rigorous demands of well intervention operations. Contact us today to discover how our advanced coiled tubing tools can optimize your operational efficiency and success.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the WNZ Wash Nozzle from Marlin Oil Tools: The Ultimate Solution for Efficient Well Cleanout Operations Marlin Oil Tools proudly presents the WNZ Wash Nozzle, a specialized downhole tool engineered for superior well intervention and cleanout operations. As an integral component of the Bottom Hole Assembly (BHA), the WNZ Wash Nozzle is designed to enhance the efficiency of well cleanouts by utilizing high-speed jets to break up and remove dense deposits from the wellbore. Key Features of the WNZ Wash Nozzle: High-Speed Jet Technology: The WNZ Wash Nozzle features nozzles that restrict cleanout fluid passage, thereby increasing the speed of the jet for effective deposit removal. Customizable Flushing Options: Offers the flexibility to customize the number, direction, and inner diameter of flushing holes to meet specific operational needs, ensuring targeted cleanout. Seamless BHA Integration: Designed to run as part of the BHA, the WNZ Wash Nozzle seamlessly integrates into well intervention workflows. Efficient Deposit Breakup: The high-speed jet mechanism is specifically engineered to break up dense deposits, making cleanout operations more efficient. Rapid Customization Capability: Marlin Oil Tools responds quickly to client requests for customized tool designs, ensuring minimal downtime and optimal tool performance. Versatile Application: Suitable for a wide range of well intervention cleanout tasks, the WNZ Wash Nozzle enhances operational flexibility and effectiveness. Elevate your well intervention and cleanout strategies with the WNZ Wash Nozzle from Marlin Oil Tools, a cutting-edge solution designed to optimize wellbore cleaning in the oil and gas industry. Leveraging high-speed jet technology, the WNZ Wash Nozzle efficiently breaks up and removes dense deposits, ensuring a clean wellbore conducive to optimal production and operational safety. With customizable flushing options and seamless BHA integration, the WNZ Wash Nozzle offers unparalleled flexibility and efficiency in well cleanout operations. Opt for Marlin Oil Tools’ WNZ Wash Nozzle for targeted, efficient, and customizable wellbore cleaning solutions. Why Choose the WNZ Wash Nozzle from Marlin Oil Tools? Targeted Cleaning Efficiency: Achieves superior cleanout performance with customizable high-speed jets. Customization to Suit Needs: Tailored flushing options provide precise control over cleanout operations. Enhanced Operational Flexibility: Adapts to various well conditions and cleanout requirements, improving operational outcomes. Quick Turnaround on Custom Designs: Marlin Oil Tools’ rapid customization process ensures tools are optimized for your specific operational needs. The WNZ Wash Nozzle by Marlin Oil Tools represents the forefront of downhole cleanout technology, providing operators with a powerful tool for maintaining well integrity and enhancing productivity. Incorporate the WNZ Wash Nozzle into your well intervention toolkit for cleaner, more efficient, and customized wellbore cleaning operations.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Grub Screw Connector Preparation Tool

GPT, Grub screw connector Preparation Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the GPT Grub Screw Connector Preparation Tool from Marlin Oil Tools: Your Essential Partner for Coil Tubing Operations Marlin Oil Tools is proud to present the GPT Grub Screw Connector Preparation Tool, a meticulously designed hand tool engineered to streamline the process of making up and removing grub screw connectors at the coil tubing end. This tool is an indispensable asset for oil and gas field operations, offering unmatched reliability and convenience for technicians and engineers alike. Key Features of the GPT Grub Screw Connector Preparation Tool: Reliable Design: The GPT features a robust construction that includes a dimple block, back hammer, and thread box, ensuring durable and dependable operation under field conditions. Efficient Operation: Designed for quick and convenient mounting or disassembly of grub screw connectors on coil tubing, the GPT enhances operational efficiency and reduces downtime. Ease of Use: As a hand tool, the GPT is engineered for ease of use in the field, enabling technicians to perform connector changes swiftly and with minimal effort. Versatile Compatibility: Suitable for a wide range of grub screw connector types and sizes, the GPT is a versatile tool that meets the diverse needs of coil tubing operations. Durable Construction: Built to withstand the rigors of oil and gas field use, the GPT promises long service life and consistent performance across countless operations. Optimized for Field Conditions: With its compact and user-friendly design, the GPT is optimized for use in various field conditions, ensuring reliability when it matters most. Elevate your coil tubing operations with the GPT Grub Screw Connector Preparation Tool from Marlin Oil Tools, a leading-edge solution designed for the efficient management of grub screw connectors in the oil and gas industry. The GPT combines a reliable design with user-friendly features, including a dimple block, back hammer, and thread box, to facilitate quick and convenient connector changes. Ideal for field technicians seeking to enhance operational efficiency, the GPT offers ease of use, durable construction, and versatile compatibility with various connector types and sizes. Opt for Marlin Oil Tools’ GPT Grub Screw Connector Preparation Tool for streamlined connector preparation and removal, ensuring smooth and efficient coil tubing operations. Why Choose the GPT Grub Screw Connector Preparation Tool from Marlin Oil Tools? Streamlined Connector Changes: Simplifies the process of making up and removing connectors, enhancing workflow efficiency. Field-Ready Design: Offers a compact and robust design tailored for the demands of oil and gas field operations. User-Centric Operation: Designed as a hand tool for maximum ease of use and operational convenience. Long-Term Reliability: Engineered with durable materials to ensure longevity and consistent performance in challenging environments. The GPT Grub Screw Connector Preparation Tool by Marlin Oil Tools represents the pinnacle of innovation in coil tubing equipment, providing a practical, efficient, and reliable solution for connector management in the field. Incorporate the GPT into your toolkit for enhanced operational efficiency and convenience in all your coil tubing endeavors.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the BBT Boot Basket from Marlin Oil Tools: The Ultimate Solution for Efficient Debris Management in Oil and Gas Operations Marlin Oil Tools is proud to present the BBT Boot Basket, a cutting-edge tool designed for optimal debris management during oil and gas drilling, milling, or garbage collection operations. Engineered to trap large pieces of sludge that cannot be circulated out of the well to the surface, the BBT Boot Basket is an essential component for maintaining clean and efficient wellbore conditions. Here’s why the BBT Boot Basket is a must-have for your operations. Key Features of the BBT Boot Basket: Efficient Debris Capture: Utilizing a unique design, the BBT Boot Basket efficiently captures large particles. The high-speed upstream flow created by the annular space's small restriction in the lower part of the tool allows for effective trapping as the flow slows down when it passes the upper part, where the gap increases sharply. Optimal Positioning: Designed to be positioned as close to the mill or bit as possible, the BBT Boot Basket ensures that milling procedures can be carried out in normal mode with standard circulation, maximizing debris capture efficiency. Enhanced Capacity Options: To accommodate varying operational needs, several BBT Boot Baskets can be used within the same Bottom Hole Assembly (BHA) to increase overall debris trapping capacity. Customizable Length: Recognizing the diverse requirements of our clients, Marlin Oil Tools offers the option to produce the BBT Boot Basket in different lengths, ensuring a perfect fit for every operation. Durability and Ease of Maintenance: The simple yet robust design of the BBT Boot Basket not only ensures excellent strength characteristics for withstanding torsion and tension but also allows for quick and easy redress, minimizing downtime and extending tool life. Elevate your wellbore cleaning operations with the BBT Boot Basket from Marlin Oil Tools, a premier solution for trapping large sludge particles during drilling, milling, or garbage collection in the oil and gas industry. Featuring an efficient design for optimal debris capture and customizable length options, the BBT Boot Basket enhances operational cleanliness and efficiency. With the capability to position the tool close to the mill or bit and the option to use multiple units for increased capacity, the BBT Boot Basket is adaptable to various operational needs. Its durable construction and easy maintenance ensure long-term reliability and performance. Choose the BBT Boot Basket for a cleaner, more efficient wellbore. Why Choose the BBT Boot Basket from Marlin Oil Tools? Superior Debris Management: Effectively traps large particles, ensuring cleaner wellbore conditions. Customizable and Versatile: Offers options for different lengths and the use of multiple baskets for increased capacity. Durable and Easy to Maintain: Designed for durability and easy redress, reducing operational downtime and costs. Optimized for Efficiency: Enhances milling procedures and maintains normal circulation, optimizing well intervention operations. For operators looking to improve their debris management strategy and maintain efficient well operations, the BBT Boot Basket by Marlin Oil Tools is the ideal solution. Contact us today to learn more about how our innovative oil and gas coiled tubing tools can benefit your operations.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the SBP Solvable Bridge Plug from Marlin Oil Tools: A Revolutionary Approach to Temporary Well Barrier Solutions Marlin Oil Tools is proud to unveil the SBP Solvable Bridge Plug, an innovative downhole tool designed for the efficient and environmentally friendly isolation of oil and gas wells. Engineered with state-of-the-art materials that fully dissolve in downhole conditions, the SBP offers a temporary barrier solution that simplifies well intervention processes and enhances operational efficiency. Key Features of the SBP Solvable Bridge Plug: Eco-Friendly Dissolution: Designed to completely dissolve over time, the SBP eliminates the need for mechanical removal, reducing environmental impact and operational costs. Efficient Well Isolation: The plug is set using a hydraulic Setting Tool (STT), ensuring a quick and secure installation to create a reliable temporary barrier and isolate underlying intervals. Fully Soluble Materials: Constructed from entirely soluble materials for both collets and the sealing element, ensuring that the plug will fully disintegrate without leaving residue. Field-Proven Reliability: The effectiveness and reliability of the SBP Solvable Bridge Plug have been rigorously tested and confirmed through extensive field work, offering peace of mind in its performance. Optimized for Oil and Gas Wells: Specifically tailored for use in oil and gas wells, the SBP is an ideal solution for operators seeking to enhance well management and operational flexibility. Streamlined Operations: By dissolving directly in the well, the SBP streamlines the workflow, eliminating the need for follow-up interventions for plug removal. Maximize your operational efficiency and environmental stewardship with the SBP Solvable Bridge Plug from Marlin Oil Tools, a leading-edge solution engineered for temporary well isolation in the oil and gas industry. Utilizing fully soluble materials that dissolve in downhole conditions, the SBP offers a reliable, cost-effective, and eco-friendly alternative to traditional bridge plugs. Set with a hydraulic Setting Tool (STT), this plug is designed to create an effective barrier and then dissolve, simplifying well interventions and eliminating the need for mechanical removal. Choose the SBP Solvable Bridge Plug for its field-proven reliability, operational efficiency, and commitment to environmental sustainability. Why Choose the SBP Solvable Bridge Plug from Marlin Oil Tools? Sustainable Well Management: Provides an environmentally friendly solution that reduces the ecological footprint of well operations. Cost-Effective Operations: Eliminates the expense and time associated with traditional plug removal, enhancing operational efficiency. Reliable Temporary Isolation: Ensures secure and effective temporary well isolation, supporting a wide range of intervention tasks. Proven in Field Applications: Backed by rigorous field testing, the SBP offers reliability and peace of mind for operators. The SBP Solvable Bridge Plug by Marlin Oil Tools represents the cutting edge in downhole tool technology, providing oil and gas operators with a smart, sustainable, and efficient solution for well isolation. Incorporate the SBP into your operations to benefit from its innovative design, operational excellence, and environmental benefits.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the MGN Radial Downhole Magnet from Marlin Oil Tools: Your Premier Solution for Well Cleaning and Metal Debris Removal Marlin Oil Tools is proud to unveil the MGN Radial Downhole Magnet, a highly efficient downhole tool designed specifically for the oil and gas industry to address the critical need for well cleaning and maintenance. Engineered to remove small metal debris, such as chips and scale, the MGN Radial Downhole Magnet is essential for maintaining well integrity and preventing operational complications. Key Features of the MGN Radial Downhole Magnet: Efficient Debris Removal: Utilizes a powerful radial magnetic field to capture and remove small metal debris accumulated during the operation of metal tools and milling operations. Prevention of Operational Complications: By extracting small metal parts and foreign objects, the MGN Radial Downhole Magnet minimizes the risk of well complications or accidents, ensuring smoother operations. Versatile Design: Features various designs with magnetic surfaces located along the tool body or from the end, tailored to maximize debris capture efficiency. Simultaneous Well Flushing Capability: Equipped with an internal passage hole, it allows for well flushing simultaneously with magnet operation, enhancing cleaning efficiency. Customizable Connections: Offers the flexibility to manufacture any connecting threads as per customer requirements, ensuring compatibility with existing downhole tool configurations. Crucial for Well Preparation: Acts as a vital step in well work preparation, ensuring a clean operational environment free from hazardous metal debris. Elevate your well maintenance regime with the MGN Radial Downhole Magnet from Marlin Oil Tools, a leading-edge solution crafted for the effective removal of metal debris in oil and gas wells. This downhole magnet, engineered for precision and efficiency, safeguards your well operations against potential complications caused by foreign metal objects and accumulated debris. With its versatile design and simultaneous well flushing capability, the MGN Radial Downhole Magnet is indispensable for any well intervention or maintenance activity. Opt for Marlin Oil Tools’ customizable and reliable downhole magnet to ensure your well remains clean, safe, and productive. Why Choose the MGN Radial Downhole Magnet from Marlin Oil Tools? Targeted Debris Removal: Optimized for capturing a wide range of metal debris, ensuring a clean wellbore. Operational Safety: Significantly reduces the risk of well operation complications and accidents. Enhanced Cleaning Efficiency: Simultaneous flushing feature streamlines well cleaning processes. Flexible and Compatible: Customizable thread options offer seamless integration into your BHA. Essential for Well Maintenance: A critical tool for preparing wells for intervention and maximizing operational longevity. The MGN Radial Downhole Magnet by Marlin Oil Tools represents the pinnacle of downhole cleaning technology, providing operators with a robust tool for ensuring well integrity and operational efficiency. Incorporate the MGN Radial Downhole Magnet into your well maintenance toolkit for a cleaner, safer, and more productive well operation.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the JKM Junk Mill from Marlin Oil Tools: The Ultimate Downhole Tool for Efficient Well Intervention and Milling Operations Marlin Oil Tools proudly presents the JKM Junk Mill, a premier downhole tool designed to optimize well intervention jobs by efficiently grinding and removing unwanted objects from the wellbore. Whether you're dealing with intentionally placed equipment such as bridge plugs or facing challenges with emergency lost equipment, the JKM Junk Mill is engineered to handle a variety of downhole obstacles with unmatched efficiency. Key Features of the JKM Junk Mill: Superior Milling Performance: Capable of grinding and washing out any object softer than the mill's cutters, ensuring clean and clear wellbores. Effective Debris Removal: Features multiple flushing holes for drilling fluid circulation, efficiently removing milled particles and cooling the cutting edge. Durable Carbide Construction: Equipped with carbide welded onto the body for robust milling action, available in crushed carbide and various insert designs to suit different milling needs. Customizable Milling Solutions: Offers a range of carbide welding designs including flat, concave, and convex bottoms, as well as top and side carbide surfacing, providing versatility for specific well intervention requirements. Extended Service Life: The durability of the carbide elements depends on the milling conditions, with Marlin Oil Tools providing redress services for worn carbide to ensure continued high performance. Powered by Downhole Motors: Rotation of the mill is performed by a downhole motor, enhancing milling efficiency and effectiveness. Elevate your well intervention strategies with the JKM Junk Mill from Marlin Oil Tools, a cutting-edge solution designed for the efficient removal of downhole obstacles in the oil and gas industry. Featuring advanced milling capabilities, effective debris removal, and durable carbide construction, the JKM Junk Mill ensures your wellbore is free from unwanted materials, enhancing operational efficiency and well productivity. With customizable carbide designs and comprehensive redress services, Marlin Oil Tools provides a versatile and reliable tool for tackling a wide range of milling challenges. Choose the JKM Junk Mill for its superior performance, durability, and adaptability, making it an essential component of your well intervention toolkit. Why Choose the JKM Junk Mill from Marlin Oil Tools? Enhanced Milling Efficiency: Delivers unparalleled performance in grinding down and removing wellbore obstructions. Versatile Application: Adaptable to various well intervention scenarios, from routine cleanouts to emergency equipment retrieval. Long-Term Durability: Constructed with high-quality carbide for extended tool life, even in the most challenging milling operations. Tailored to Your Needs: Offers customization options to match your specific well intervention requirements, maximizing tool effectiveness. The JKM Junk Mill by Marlin Oil Tools represents the forefront of downhole milling technology, offering oil and gas operators a powerful solution for enhancing well intervention outcomes. Incorporate the JKM Junk Mill into your operations for smoother, more effective wellbore preparation and obstacle management.

Buy

Made to Order

Manufacturer

New

API

Land Freight

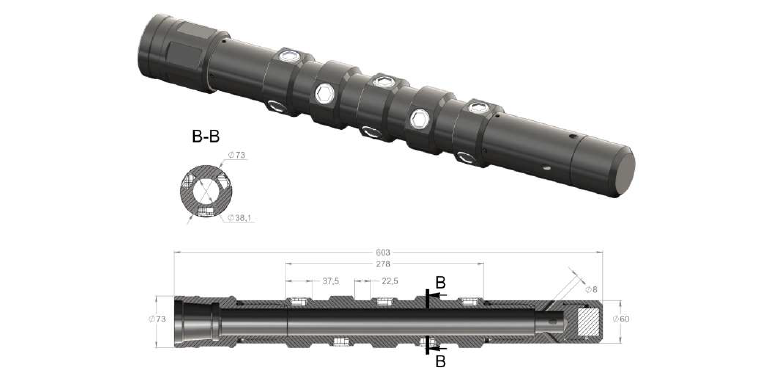

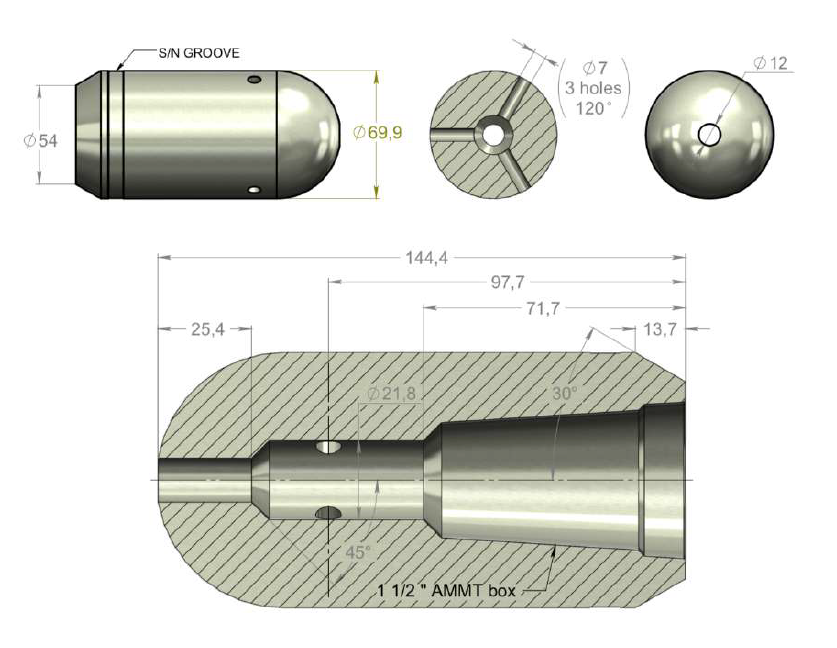

Introducing the BPV (Back Pressure Valve) from Marlin Oil Tools: The Essential Safety Barrier for Coiled Tubing Operations in the Oil and Gas Industry Marlin Oil Tools is proud to present our BPV (Back Pressure Valve), a paramount downhole tool designed to enhance safety and operational integrity during well intervention tasks. Engineered with precision and reliability, the BPV is an indispensable component for maintaining control over well pressure and ensuring the protection of coiled tubing (CT) from potential hazards. Here's a detailed look at the BPV's design, functionality, and benefits, making it a must-have tool for any oil and gas operation. Key Features of the BPV (Back Pressure Valve): Directional Fluid Flow Control: The BPV is designed to allow fluid flow exclusively in one direction—downwards. This capability is crucial for preventing backflow and maintaining operational control during well intervention processes. Dual Flapper Valve System: Equipped with two duplicate cartridges featuring reliable flapper valves, the BPV offers an enhanced level of safety and redundancy. This double flapper back pressure valve system ensures that even if one valve encounters an issue, the other can continue to function effectively, providing an uninterrupted safety barrier. Comprehensive Well Pressure Control: The primary function of the BPV is to act as a safety barrier, preventing well fluids from entering the coiled tubing through the bottom of the Bore Hole Assembly (BHA). This function is vital for the safety of operations and the preservation of equipment integrity. Protection Against Mechanical Particles and Aggressive Environments: In addition to controlling well pressure, the BPV serves an auxiliary role in protecting the coiled tubing from mechanical particles and potentially aggressive well environments, such as those containing H2S and CO2. These elements can cause significant damage to the CT if allowed entry, making the BPV's protective capability critical for long-term equipment durability. Essential Tool for Every Job: Given its crucial safety and protective functions, the BPV is typically run on each well intervention job, underscoring its importance in the toolkit of downhole operations. Elevate your well intervention safety and efficiency with the BPV (Back Pressure Valve) from Marlin Oil Tools, a leading solution in oil and gas coiled tubing tools. Designed for downhole applications, the BPV features a double flapper valve system to ensure fluid flows only downwards, creating an effective barrier against well pressure. This safety essential prevents well fluid backflow into the CT, offering protection from mechanical particles and harsh environments like H2S and CO2. With dual reliable cartridges, the BPV is a critical component for every well intervention job, safeguarding both personnel and equipment by maintaining operational integrity and preventing damage from aggressive well conditions. Why Choose the BPV from Marlin Oil Tools? Unparalleled Safety and Control: Provides a reliable safety barrier for well pressure control, crucial for operational safety. Dual Valve Redundancy: Ensures continued operation and safety even if one valve fails, thanks to its double flapper valve design. Comprehensive Protection: Guards coiled tubing against mechanical damage and corrosion from aggressive well environments. Operational Necessity: An indispensable tool for every well intervention job, highlighting its importance in maintaining a safe and efficient operation. The BPV (Back Pressure Valve) by Marlin Oil Tools represents the pinnacle of safety and efficiency in coiled tubing operations within the oil and gas industry. Incorporate the BPV into your operations to ensure the highest standards of safety and equipment integrity. Contact Marlin Oil Tools today to learn more about how our innovative solutions can support your operational needs.

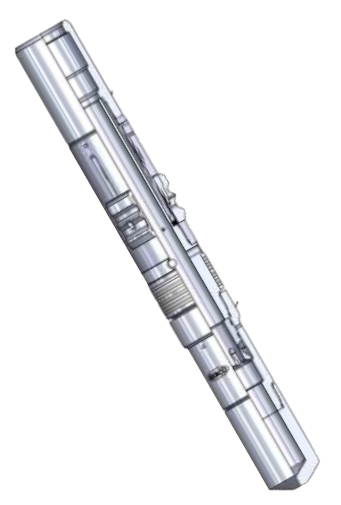

X-Span Casing Patch Deployment System

Casing Patch Setting Tool![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Deploying X-SPAN systems has never been easier! With a range of multi-stage explosive, electric line non-explosive or hydraulic setting tools available, our X-SPAN systems can be deployed quickly and efficiently in any well application. Our explosive setting tools can be initiated electrically, on e-line or slick line using a variety of compatible firing systems. For conventional tubing or coil tubing deployment requirements, several sizes of hydraulically operated setting tools are available to meet your specific needs. Our X-SPAN systems are not only easy to deploy, but they are also easy to remove. Simply mill off the sealing elements and your well is ready for the next application. We take pride in the reliability and quality of our X-SPAN systems, which have been proven many times with over 2900 successful installations completed with a 98% success rate when setting depth has been achieved. At ID OILTOOLS, we are committed to providing our customers with the highest quality and most reliable products on the market. Contact our Tech Services department today to learn more about our X-SPAN systems and how they can benefit your well application.

Buy

In Stock

Product & Service

New

API

Sea Freight

![]() CWB National Leasing in Winnipeg

CWB National Leasing in Winnipeg

Advance Your Manufacturing with Laser Cutting Tool Leasing from CWB National Leasing Elevating Precision and Efficiency in Your Operations with Strategic Leasing Solutions For businesses in manufacturing, engineering, or design, laser cutting tools are indispensable for precision cutting and fabrication. Leasing laser cutting tools through Canadian Western Bank (CWB) National Leasing offers a flexible, financially savvy solution for businesses aiming to enhance their manufacturing capabilities. Here’s how leasing laser cutting tools can revolutionize your operational processes: 1. Rapid Equipment Access CWB National Leasing values the pace of your business operations and offers a quick leasing process. Decisions are typically made within 48 hours of your application, ensuring fast notification to your equipment dealer. This efficiency means your laser cutting tools can be delivered and operational quickly, minimizing downtime and boosting productivity. 2. Enhanced Financial Flexibility Leasing laser cutting tools with CWB National Leasing increases your buying power. Opting for periodic payments over a large upfront purchase helps free up capital for other critical aspects of your business. Furthermore, the option to add extra features or accessories to your laser cutting tools for a small payment increase allows for customization to meet specific operational needs. 3. Effective Cash Flow Management With manageable lease payments spread over the term, your laser cutting tools begin contributing to your business’s revenue while still being paid off. This balanced financial strategy is key in maintaining a healthy expense-to-revenue ratio, essential for business growth and sustainability. 4. Customizable Payment Plans CWB National Leasing offers a range of payment options, including seasonal, semi-annual, or annual plans, tailored to align with your business’s financial cycle. This flexibility is especially beneficial for businesses with variable or seasonal income, ensuring that payments are practical and aligned with your financial situation. 5. Potential Tax Advantages Leasing laser cutting tools can offer tax benefits, such as the ability to expense lease payments instead of capitalizing the cost of the equipment. Consulting with a tax advisor is advisable to understand how leasing can positively impact your business’s tax position. Conclusion Opting to lease laser cutting tools through CWB National Leasing is a strategic decision that empowers your business with advanced manufacturing equipment while maintaining financial agility. It ensures access to state-of-the-art laser cutting technology, vital for precision and efficiency in production, without the financial strain of a large upfront investment. This leasing approach enables enhanced operational capabilities, increased production capacity, and greater profitability, helping your business to excel in the competitive manufacturing industry.

Service

In Stock

Service

New

ISO

HDI Gauge Batteries, Parts, and Repair Kits

Gauge Parts![]() Houston Digital Instruments in Houston

Houston Digital Instruments in Houston

At Houston Digital Instruments (HDI Gauges), we prioritize providing our customers with cost-effective solutions that maximize the lifespan and performance of our products. We understand the importance of minimizing downtime and inventory costs while ensuring optimal functionality. That's why we offer a range of options for maintenance and repair, including spare parts, batteries, and repair kits. Additionally, our certified repair and calibration services guarantee the highest level of quality and precision. Let's explore how HDI Batteries, Parts, and Repair Kits can enhance your operational efficiency. Field Repairability: Minimize Lifecycle Costs HDI products are designed with field repairability in mind, significantly reducing the lifecycle costs associated with using our instruments. We believe in empowering our customers to perform maintenance and repairs on their own, enabling them to minimize downtime and spare unit inventory costs. Our DIY maintenance options are user-friendly and straightforward, ensuring that you can quickly resolve issues and keep your operations running smoothly. Spare Parts and Batteries: Keep Your Instruments Performing Optimally To support your maintenance efforts, HDI offers a comprehensive range of spare parts and batteries for our products. Whether you need replacement components, sensors, connectors, or other essential parts, our inventory has you covered. By utilizing genuine HDI spare parts, you can maintain the integrity and performance of your instruments, ensuring accurate and reliable measurements in the field. Furthermore, HDI batteries are specifically designed to deliver long-lasting power and reliability. We understand the critical nature of uninterrupted operation, and our batteries are engineered to provide optimal performance, even in demanding environments. With HDI batteries, you can trust that your instruments will continue to perform at their best, enhancing your productivity and efficiency. Repair Kits: Convenient Solutions for Maintenance and Repairs HDI Repair Kits are carefully curated packages that include all the necessary components and tools to perform maintenance and repairs on your HDI instruments. These kits are designed to simplify the process, providing you with a convenient solution to address common issues quickly. With HDI Repair Kits, you can efficiently resolve minor problems, minimize downtime, and restore your instruments to peak performance. Certified Repair and Calibration: Uncompromising Quality and Precision For more complex repairs or calibration needs, HDI offers certified repair and calibration services. If you prefer to have our expert technicians handle the maintenance and calibration of your instruments, simply ship them back to HDI. Our skilled professionals will carefully assess, repair, and calibrate your instruments, ensuring they meet our stringent quality standards. With HDI certified repair and calibration, you can have complete confidence in the accuracy and reliability of your instruments. HDI Batteries, Parts, and Repair Kits provide you with comprehensive solutions to enhance the lifespan and performance of your HDI instruments. Our commitment to field repairability allows you to minimize lifecycle costs, reduce downtime, and optimize inventory management. By utilizing genuine HDI spare parts, reliable batteries, and convenient repair kits, you can keep your instruments performing at their best. Additionally, our certified repair and calibration services ensure uncompromising quality and precision. Trust HDI Gauges for all your maintenance and repair needs, and experience the benefits of our cost-effective solutions. Contact HDI today to explore our range of batteries, parts, and repair kits tailored to meet your specific requirements.

Buy

In Stock

Manufacturer

New

API

Air Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

InWaTec Combined: Ensuring Well Integrity with Advanced Pulling and Setting SCSSV Services The oil and gas industry faces the critical challenge of maintaining well integrity for uninterrupted production. At InWaTec Combined, we understand the importance of robust well operations, and our Pulling and Setting Surface Controlled Subsurface Safety Valve (SCSSV) services are at the forefront of addressing this challenge. Revolutionizing DHSV Repair A malfunctioning Downhole Safety Valve (DHSV) can halt production and compromise well integrity, making timely and efficient repairs crucial. Our services are meticulously designed to repair Tubing Retrievable Subsurface Safety Valves (TRSSSV), a process that not only restores well integrity but also resumes production swiftly. By repairing TRSSSVs, we circumvent the need for lock open operations, avoiding the necessity of installing a Wireline Retrievable Subsurface Safety Valve (WRSSSV) which could potentially restrict production flow. Optimized Repair Techniques Conventional repair methods are often time-consuming and costly, requiring extensive workover operations. InWaTec Combined’s approach replaces these outdated methods with cutting-edge techniques that save time and reduce costs. Our expertise in pulling and setting SCSSVs ensures that if a TRSSSV's functionality and integrity cannot be restored, it can be locked open efficiently. We then install a WRSSSV, which is a strategic move that prevents the need for a complex workover, thereby optimizing the repair process. Maintaining Peak Performance The ability to swiftly switch from a TRSSSV to a WRSSSV without a full workover is a game-changer in well service operations. It minimizes downtime and ensures that wells can continue to operate at peak performance levels. Our dedicated teams are equipped with the latest technology and have the expertise to execute these operations seamlessly, ensuring minimal disruption to your production schedules. A Partner in Well Integrity At InWaTec Combined, we pride ourselves on being your trusted partner in maintaining well integrity. Our Pulling and Setting SCSSV services are not just about repairs; they are about providing a comprehensive solution that safeguards your operations against future integrity issues. With our advanced techniques and committed service, we guarantee that your wells remain productive, secure, and profitable. In conclusion, InWaTec Combined is dedicated to providing superior service in the repair and maintenance of SCSSVs. Our innovative approach is designed to keep your wells functioning smoothly, ensuring that well integrity is not just restored but fortified. Trust us to be the guardians of your well's safety and productivity.

Service

In Stock

Service

New

API

Land Freight

![]() Canaweld Inc. in Vaughan

Canaweld Inc. in Vaughan

Introducing the Canaweld Welder Cart for Single Phase Machines - Your Ultimate Welding Companion! When it comes to welding, having the right equipment at your fingertips is essential. That's why we've designed the Canaweld Welder Cart - a sturdy and reliable cart that will keep your single-phase machines organized and accessible at all times. With its thoughtful features and robust construction, this cart is the perfect addition to your welding setup. Built for Strength and Durability: The Canaweld Welder Cart is crafted with a strong steel construction that ensures it can handle the demands of the oil and gas industry. Its powder coat finish adds an extra layer of protection, making it resistant to wear and tear from daily use. Rest assured, this cart is built to last. Maximum Convenience, Minimum Effort: Moving your welding equipment has never been easier. The front caster wheels on our cart swivel a full 360 degrees, allowing for smooth and effortless turning. No more struggling to maneuver your machines - our cart does the work for you. Ample Storage Space: Organize your welding essentials with ease. The Canaweld Welder Cart features three-tier shelves thoughtfully designed to accommodate all your portable MIG welders, stick welders, plasma cutters, and necessary accessories. Plus, there's enough room for consumables and a gas cylinder, ensuring you have everything you need at your fingertips. Secure Your Equipment: Your safety is our priority. That's why we've equipped the cart with a chain to secure the gas tank firmly in place. Worried about keeping your cables and helmet tidy? The side hook provides a convenient storage solution for them, eliminating clutter and potential hazards. Unbeatable Dimensions: The Canaweld Welder Cart boasts spacious shelf dimensions that perfectly cater to your welding equipment: • Top Shelf: 18 X 11 X 1 inches • Middle Shelf: 15.5 X 11 X 1 inches • Lower Tray: 27.7 X 11.5 X 2 inches • Gas Bottle Space: 10.2 X 11.4 X 2 inches Ultimate Load Capacity: Our cart can handle the weight. With a load capacity of 110 lbs. (50 kg), you can trust that your valuable equipment is safe and secure while on the move. Efficiency Meets Style: The Canaweld Welder Cart is more than just a functional tool - it's a sleek and stylish addition to your welding setup. Its design not only optimizes your workflow but also adds a touch of professionalism to your workspace. Upgrade Your Welding Experience: Say goodbye to the hassle of transporting your welding equipment and embrace the convenience of the Canaweld Welder Cart. It's time to work smarter, not harder. Elevate your welding experience today with Canaweld - your trusted partner in welding solutions.

Buy

In Stock

Manufacturer

New

ASME

Land Freight

Offshore Electric Line Services

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Navigating the Depths: InWaTec Combined's Advanced Offshore E-Line Services In the challenging and complex world of offshore operations, precise and dependable wellbore data transmission is not just beneficial—it's crucial. At InWaTec Combined, our Offshore Electric Line (E-Line) services are the cornerstone of our well diagnostics and intervention solutions, designed to conquer the unique demands of the offshore environment. An E-Line, in its simplest form, is a robust electric cable. Yet, when deployed by InWaTec Combined, it becomes an integral part of offshore operations, a sophisticated tool that delves into the wellbore's mysterious realms. Our E-Line services excel in transmitting real-time data about the wellbore's conditions back to our offshore experts, ensuring that critical decisions are made with the utmost information at hand. Our E-Line's forte lies in its versatility and utility in conducting a plethora of logging activities essential for evaluating the well's integrity, formation properties, and hydrocarbon potential. These activities enable a comprehensive understanding of the well, providing insights necessary for optimizing production and ensuring the safety of offshore operations. The offshore environment poses unique challenges with its unpredictable nature and the sheer scale of operations. InWaTec Combined's E-Line services are designed to be resilient and adaptable, capable of withstanding the high pressures and corrosive elements found in the deep sea. Our commitment to innovation means that our E-Line technology is continuously evolving, pushing the boundaries of what is possible in offshore data gathering. By choosing InWaTec Combined's Offshore E-Line services, our clients receive more than just data—they gain a strategic advantage. With our advanced technology and expert analysis, we provide the insights necessary to maximize well performance, extend the life of offshore assets, and enhance the overall safety and efficiency of offshore operations. In an industry where the margin for error is slim and the consequences significant, InWaTec Combined stands as a beacon of reliability and excellence. Our Offshore E-Line services are not just a component of your operations—they are a pivotal part of your success story, deep beneath the waves.

Service

In Stock

Service

New

API

Land Freight

![]() ALCiT in Mississauga

ALCiT in Mississauga

Stay Cybersecure with ALCiT: Your Shield in an Uncertain Digital Realm In a world where digital threats lurk at every corner, staying cybersecure is no longer an option—it's a necessity. But we get it; navigating the intricacies of cybersecurity can be overwhelming, even frightening. That's where we come in, your unwavering allies in the pursuit of digital safety. Empowerment Through Expertise ALCiT stands as a beacon of assurance in the cybersecurity landscape. As trusted experts, we specialize in assisting Small and Medium Enterprises (SMEs) on their journey to become and remain cybersecure. You've laid the foundation, you've improved your cyber resiliency, and now it's time to complete the puzzle by staying cybersecure. Master the Art of Staying Secure Cyber threats are relentless, but so are we. With ALCiT's managed services, you can confidently detect cyber threats, respond to incidents, and maintain your cybersecure stronghold. Our solutions go beyond the traditional; they encompass a holistic approach that equips your organization with the tools and strategies needed to stay ahead. Why Choose Cybersecurity with ALCiT? Tech in Check: Keeping your technology secure is our priority. We diligently monitor, update, and optimize your tech environment, ensuring every vulnerability is addressed and every weakness fortified. Team Training: Empower your team to be your first line of defense. Our comprehensive training programs arm them with the knowledge to identify and respond effectively to potential threats. Vigilance is Key: Staying vigilant is half the battle. Our managed services include real-time monitoring, ensuring that any abnormal activity is detected and neutralized promptly. Effective Response: Cyber incidents can strike anytime. With ALCiT by your side, you're equipped to respond swiftly and effectively, minimizing potential damage and ensuring business continuity. Efficient Recovery: The aftermath of an attack can be daunting, but we've got your back. ALCiT's recovery strategies are designed to expedite your return to normalcy, reducing downtime and impact. Secure Today, Thrive Tomorrow ALCiT stands for more than just services; we stand for security, empowerment, and peace of mind. Let us be your cybersecurity partner as you navigate the intricate landscape of digital threats.

Service

Made to Order

Service

New

ISO

![]() ALCiT in Mississauga

ALCiT in Mississauga

Unlock Seamless Cloud Connectivity with ALCiT's Megaport Partnership In today's digital landscape, the power of connectivity reigns supreme. ALCiT stands shoulder to shoulder with Megaport, a trailblazing company founded in Australia in 2013. Our partnership brings you a future where simplicity, control, and choice converge to transform how you connect, collaborate, and innovate. Welcome to a realm where cloud-to-cloud connections are optimized with unprecedented ease. Megaport: Shaping Connectivity with Vision Founded on the principles of simplicity, control, and choice, Megaport sets the stage for a new era of connectivity. Their mission? To empower you with the ability to shape your connections, services, and applications to align with your business's unique needs. ALCiT proudly embraces this mission, offering you the power of seamless cloud connectivity. Cloud-to-Cloud: Seamlessly and Securely Connected Megaport's hybrid cloud architecture revolutionizes cloud-to-cloud connections. Whether it's data mobility, flexibility, or affordability, Megaport ensures that your cloud-based assets seamlessly flow to where you need them. Say goodbye to complexity; say hello to convenience. Exploring Megaport's Infrastructure Benefits Simplicity at Your Fingertips: Megaport's platform offers a unified hub where all your cloud-based apps and products converge. Manage everything in one place, streamlining your operations with ease. Speed Beyond Limits: Megaport's multi-region network guarantees lightning-fast connectivity, enabling you to work anytime, anywhere. Time is of the essence, and Megaport ensures you're never left waiting. Control in Your Hands: With centralized management and adaptable bandwidth options, Megaport's solution molds to your needs. It's not just cost-effective; it's also a secure route to optimized connectivity. Shape Your Connectivity, Define Your Success ALCiT and Megaport are more than partners; we're architects of your digital future. Our collaboration reshapes how you connect, innovate, and succeed in the digital realm. Experience the power of ALCiT's partnership with Megaport.

Service

Made to Order

Service

New

ISO

![]() Cleanstream B.V. in Ter Apel

Cleanstream B.V. in Ter Apel

Introducing HCR-3000: The Safe and Effective Synthetic Acid™ Replacement At Cleanstream, we're committed to delivering high-performance oilfield solutions that are both environmentally responsible and safe for workers. That's why we're proud to introduce HCR-3000, our latest Synthetic Acid™ replacement product that delivers the same results as mineral acids but without the halogen content. HCR-3000 is a strong, non-fuming, and non-oxidizing acid alternative that can be used in a variety of oilfield applications, including scale removal, well stimulation, and acidizing. Unlike traditional mineral acids, HCR-3000 is non-corrosive to skin and safe on chrome and chrome plating, making it a safer and more reliable choice for your operations. With its comprehensive spending nature, HCR-3000 is an excellent choice for operators looking to cut down on chemical costs. Plus, its non-fuming, non-regulated formula makes it easy and safe to transport and handle, reducing the risk of accidents and exposure to hazardous chemicals. But don't let its eco-friendly and worker-safe properties fool you. HCR-3000 is a powerful acid replacement that delivers high-temperature stability of over 1800C, making it an excellent choice for high-temperature applications. And with the ability to be enhanced through the addition of conventional oilfield chemistry, HCR-3000 can be customized to meet your specific needs and requirements. Say goodbye to traditional mineral acids and hello to HCR-3000, the safer, more effective Synthetic Acid™ replacement from Cleanstream.

Buy

In Stock

Manufacturer

New

ISO

Land Freight

![]() CWB National Leasing in Winnipeg

CWB National Leasing in Winnipeg